Polycrystalline silicon ingot furnace

A polysilicon ingot casting furnace and furnace body technology, which is applied in the direction of polycrystalline material growth, crystal growth, single crystal growth, etc., can solve the problems of unreasonable distribution of heat insulators, short service life, poor safety performance, etc., and achieve good Crystal growth effect, good purification, and safety protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

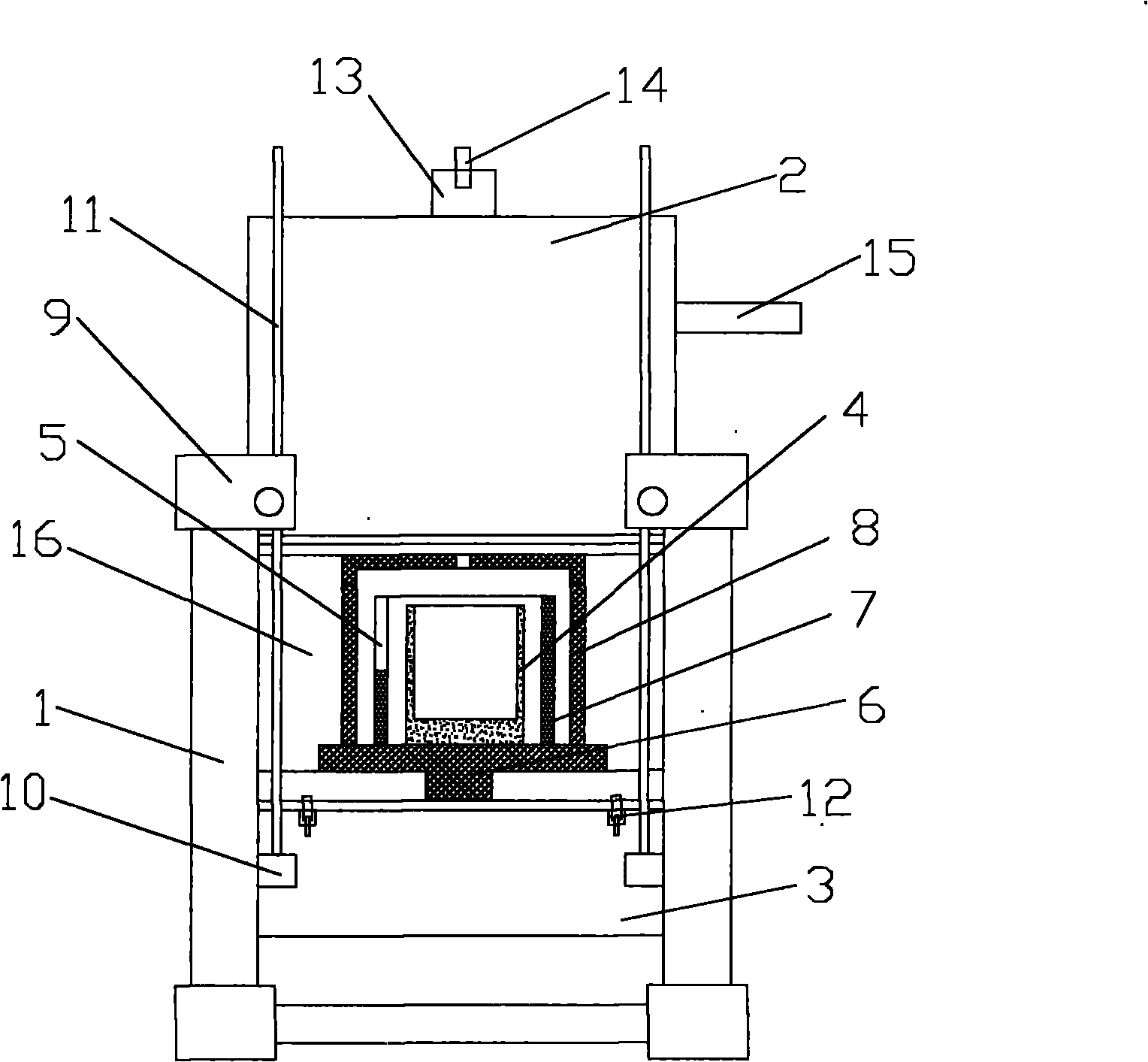

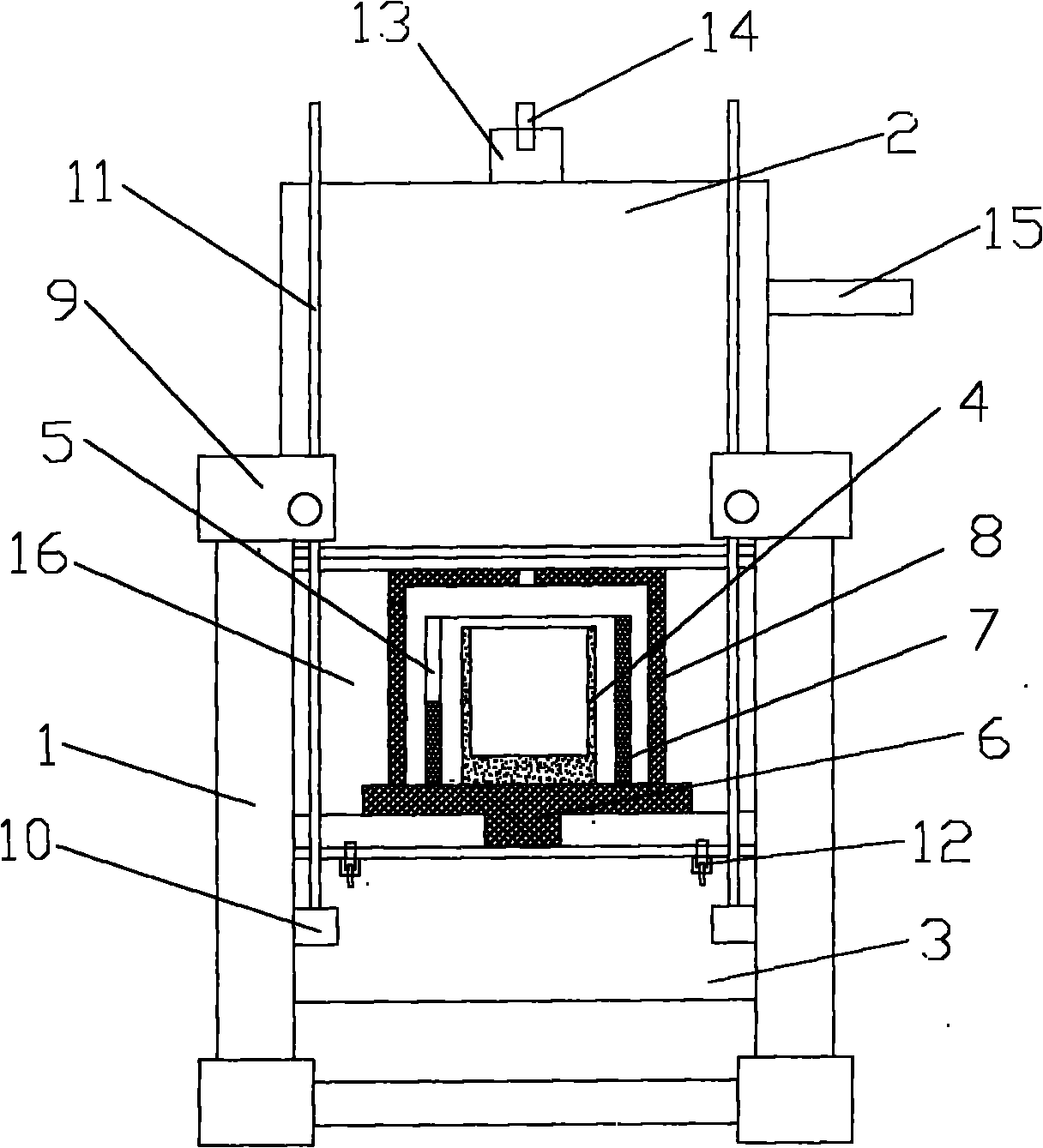

[0016] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0017] Such as figure 1 A polysilicon ingot casting furnace shown includes a furnace body and a support 1, the furnace body is fixed on the support 1, a support plate 6 is arranged in the furnace body, a crucible 4 is arranged on the support plate 6, and the The furnace body includes an upper furnace body 2 and a lower furnace body 3, a lifting device is connected between the upper furnace body 2 and the lower furnace body 3, a vacuum interface 15 is provided at one end of the upper furnace body 2, and a vacuum interface 15 is provided outside the crucible 4 There is a heater 5, and the outer button of the heater 5 is cover...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap