Conical surface mechanical sealing device

A mechanical seal device and conical surface technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of increased friction and wear, circumferential pressure pulsation, and the mechanical seal on the end face needs to be strengthened, etc. , Good resistance to torsional deformation of shaft section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

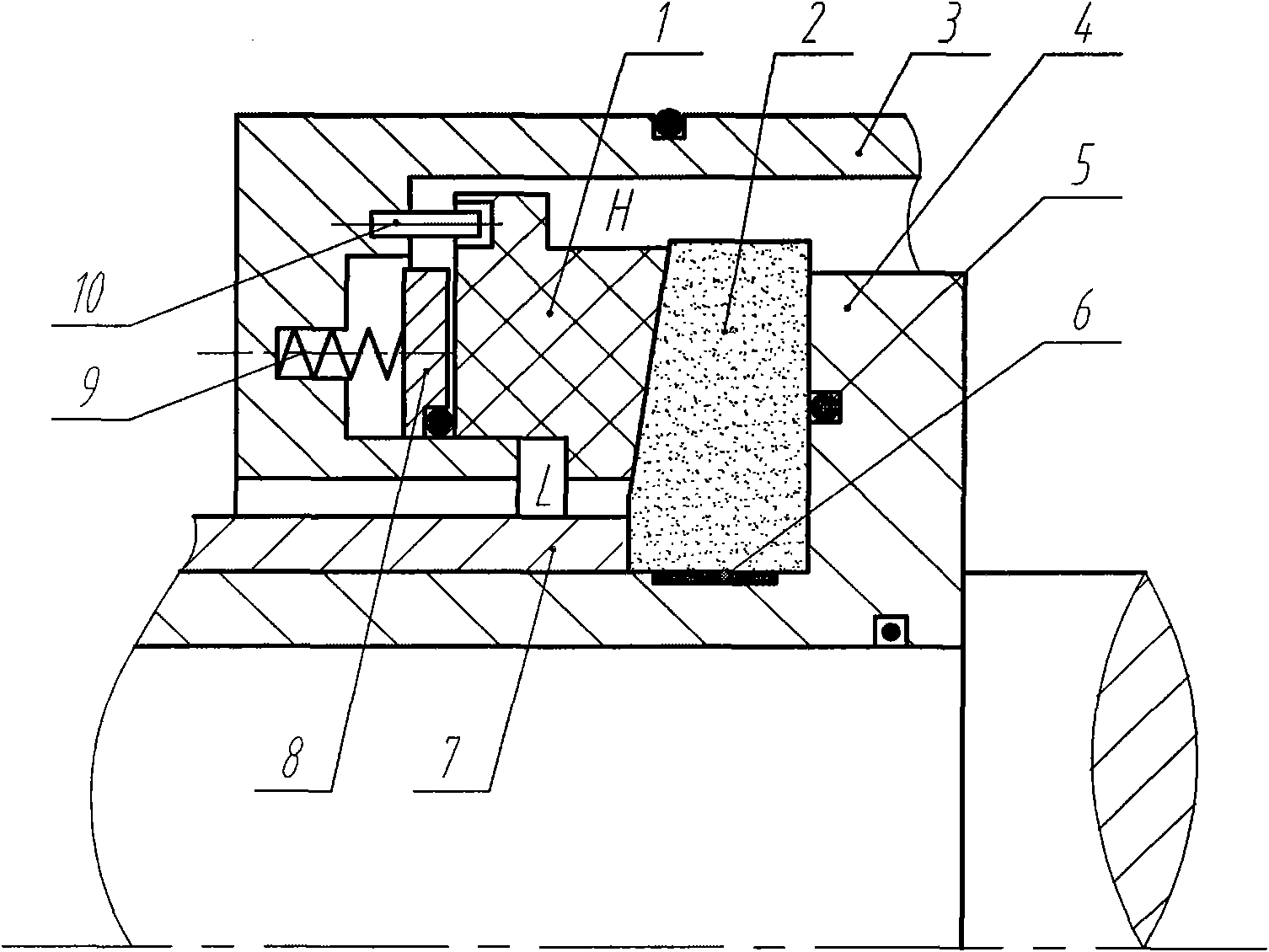

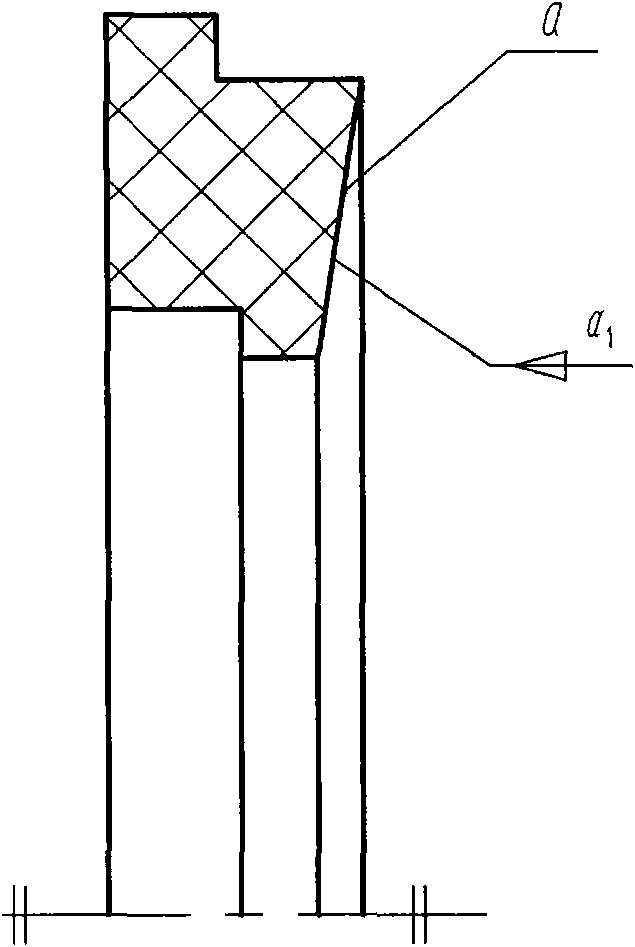

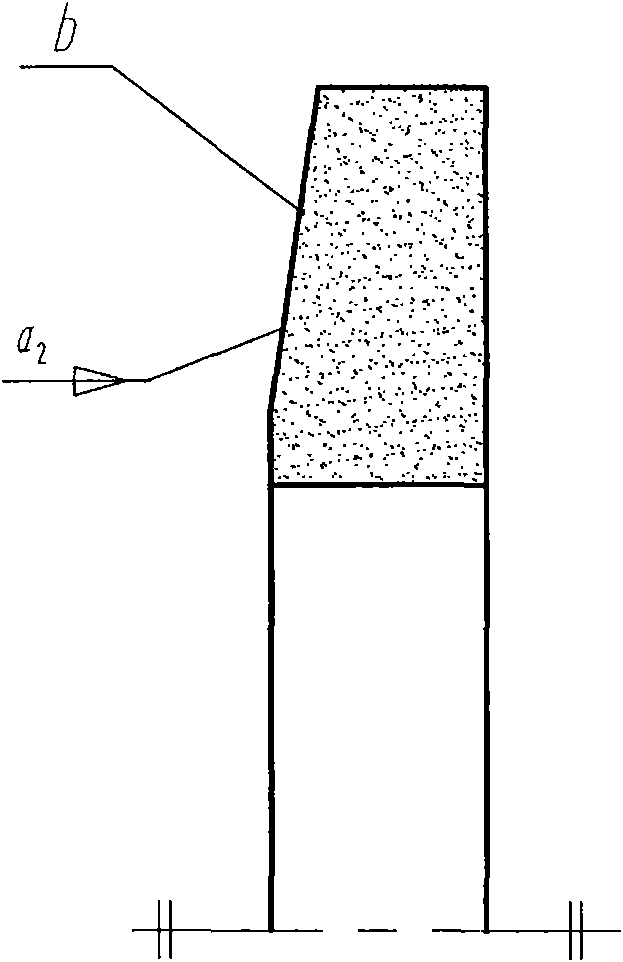

[0047] Embodiment 1: see figure 1 , figure 2 , image 3

[0048] figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention. The tapered mechanical seal device includes a stationary ring 1 with a tapered surface a, a rotating ring 2 with a tapered surface b, a stationary ring seat 3, a shaft sleeve 4, an "O" ring 5, a tolerance ring 6, and a compression sleeve 7. Push ring 8, spring 9, anti-rotation pin 10, etc. The feature of this embodiment is that the two sealing surfaces (namely: the cone surface a and the cone surface b) are in direct contact.

[0049] according to figure 1 , figure 2 , image 3 , the tapered surface a on the stationary ring 1 is a tapered hole surface, and its taper is α 1 , the conical surface b on the rotating ring 2 is a conical surface, and its taper is α 2 , the relationship between the two tapers is: α 1 ≥α 2 . The stationary ring 1 and the rotating ring 2 are installed face-to-face and coaxially to form a...

Embodiment 2

[0051] Embodiment 2: see Figure 4

[0052] Figure 4 It is a structural schematic diagram of Embodiment 2 of the present invention. The tapered mechanical seal device includes a stationary ring 1 with a tapered surface a, a rotating ring 2 with a tapered surface b, a stationary ring seat 3, a shaft sleeve 4, an "O" ring 5, a tolerance ring 6, and a compression sleeve 7. Push ring 8, spring 9, anti-rotation pin 10, etc. The characteristic of this embodiment is that the two sealing surfaces (namely: the cone surface a and the cone surface b) are separated by a small gap h0.

[0053] according to Figure 4 , the tapered surface a on the stationary ring 1 is a tapered hole surface, and its taper is α1 , the conical surface b on the rotating ring 2 is a conical surface, and its taper is α 2 , the relationship between the two tapers is: α 1 ≥α 2 . The stationary ring 1 and the rotating ring 2 are installed face-to-face and coaxially to form a tapered sealing surface, and a ...

Embodiment 3

[0055] Embodiment 3: see Figure 5 , Image 6

[0056] Figure 5 , Image 6 It is a structural schematic diagram of Embodiment 3 of the present invention. The tapered mechanical seal device includes a stationary ring 1 with a tapered surface a, a rotating ring 2 with a tapered surface b, a stationary ring seat 3, a shaft sleeve 4, an "O" ring 5, a tolerance ring 6, and a compression sleeve 7. Push ring 8, spring 9, anti-rotation pin 10, etc. The characteristic of this embodiment is that a fluid dynamic pressure groove c is provided on the conical sealing surface b of the moving ring.

[0057] according to Figure 5 , the tapered surface a on the stationary ring 1 is a tapered hole surface, and its taper is α 1 , the conical surface b on the rotating ring 2 is a conical surface, and its taper is α 2 , the relationship between the two tapers is: α 1 ≥α 2 . The stationary ring 1 and the rotating ring 2 are installed face-to-face and coaxial to form a tapered sealing su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com