Gas ratio proportioning valve, multi-gas ratio proportioning combination valve and gas proportioning system

A proportioning valve and gas technology, which is applied to multi-port valves, valve devices, engine components, etc., can solve the problems of difficult production and debugging, reduced proportioning accuracy, inconvenient use, etc., and achieves intuitive and convenient debugging, convenient production and debugging, The effect of high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

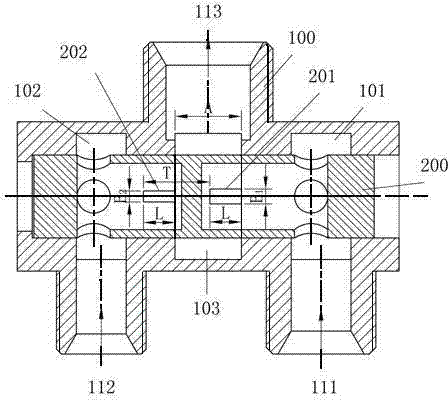

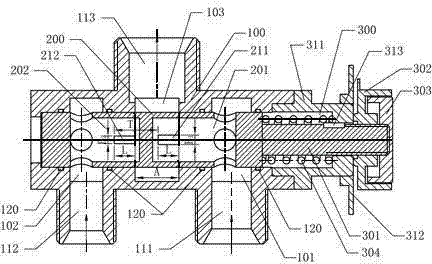

[0052] see image 3 and Figure 4 , the gas proportioning valve involved in this embodiment includes a valve body 100 , a valve core 200 , and an adjustment indicating device 300 .

[0053] Among them, the valve body 100 is a three-chamber shell coaxially penetrated through the center, including the main air inlet chamber 101 on one side and the main air inlet port 111 communicating with it, and the auxiliary air inlet chamber 102 on the other side and the auxiliary inlet chamber communicating with it. The air port 112, the air mixture chamber 103 in the middle and the air outlet 113 communicating with it.

[0054] The valve core 200 is located in the center of the inner cavity of the valve body, coaxially matched with the inner cavity of the valve body 100, and isolates the main air intake cavity 101, the auxiliary air intake cavity 102, and the mixed air cavity 103 of the valve body 100 from each other, wherein the valve At least one of the spool 200 on the side 101 of the...

Embodiment 2

[0086]The gas proportional proportioning valve involved in this embodiment is basically the same as the first embodiment, only an isolation ring 121 is added in the middle of the middle mixing chamber 103, and the isolation ring 121 divides the central inlet of the mixing chamber 103 into two parts, and the isolation ring 121 The axial length A is equal to the distance T between the outlets 211 and 212 of the main and auxiliary control passages in the spool 200 .

[0087] The initial working state of this embodiment is as Figure 5 As shown, its proportional adjustment state is as Figure 6 As shown, on the spool 200, the direction of the pressure difference between the auxiliary gas side pressure and the main gas side pressure is opposite to the moving direction of the spool. 212 moves in the direction of closing, as shown in formula (c), it also moves in the direction of concentration reduction. The larger the pressure difference between the auxiliary gas side pressure and ...

Embodiment 3

[0089] In practical applications, the adjustment range of the gas ratio concentration is generally not greater than 50%. When the concentration is greater than 50%, the concentration is still less than 50% after the main and auxiliary air intakes are reversed. The proportioning valve involved in this embodiment is this kind of proportioning valve, and its adjustment range is <50%.

[0090] The adjustment stroke S of the proportioning valve spool 200 does not need to be as long as in Examples 1 and 2. It is only necessary to ensure that the total width of the outlet 211 of the main control channel on the spool 200 and the total width of the outlet 212 of the auxiliary control channel have the following relationship within the range of the spool adjustment stroke:

[0091] B 1 / ρ 1 0.5 = B 2 / ρ 2 0.5 ,

[0092] That is to say, the linear relationship between the gas mixture concentration and the stroke of the valve core 200 in formula (c) can be achieved.

[0093] The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com