FFC (Flexible Flat Cable) dimension check device

A technology for dimensional inspection and mounting boards, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of affecting inspection accuracy, reducing inspection efficiency, and affecting inspection efficiency, so as to improve inspection efficiency, reduce inspection time, and displacement errors Eliminate the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

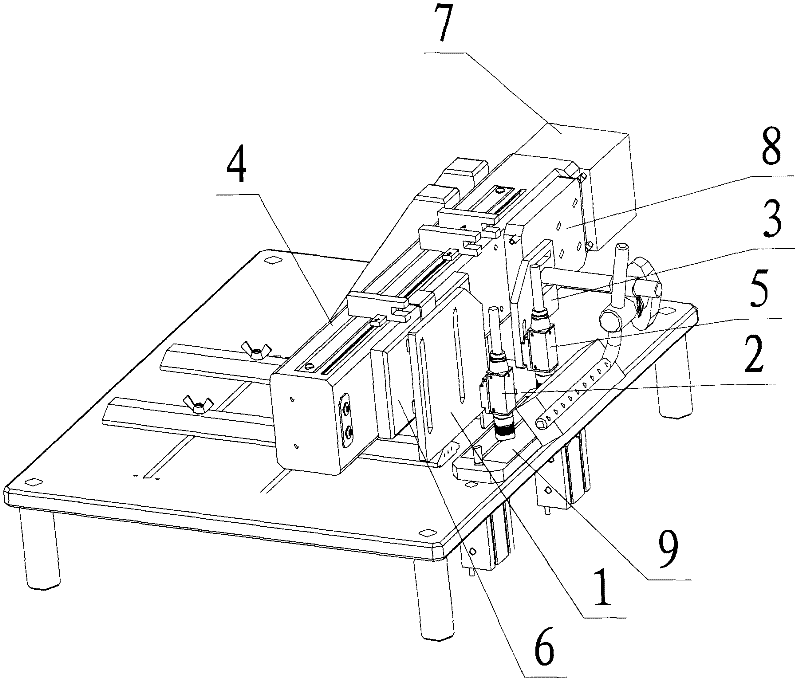

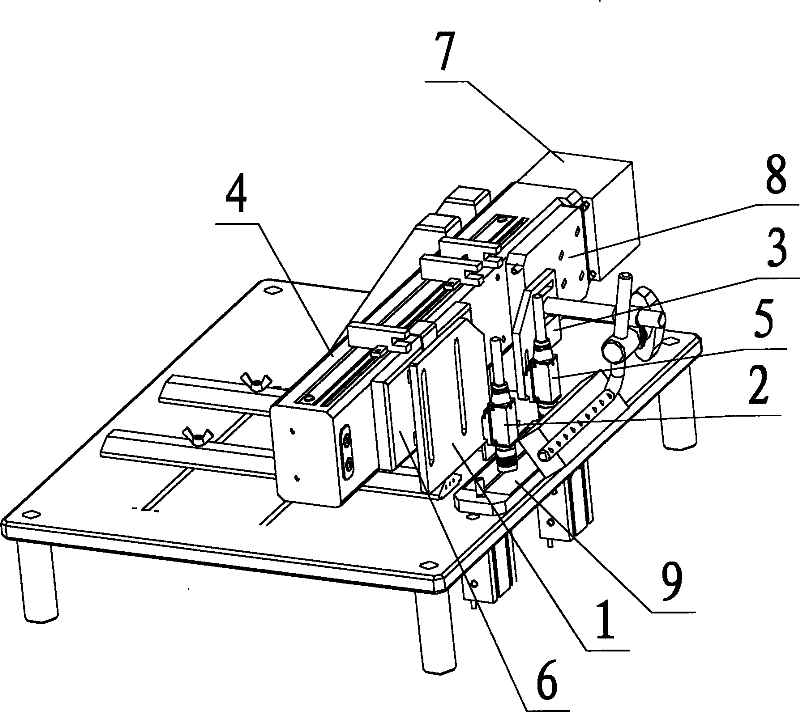

[0018] Such as figure 1 As shown, a specific embodiment of the present invention is an EK inspection machine, including a single-axis slide table 4, on which a sensor induction sheet mounting plate 6 is arranged, and the sensor induction sheet installation plate 6 can be mounted on a stepping motor 7 Under the action of the screw, it moves along the length direction of the single-axis slide table 4.

[0019] The "E" and "K" referred to by the EKFFC size inspection device refer to the E size and K size of Hitachi wire pair products, and "E" and "K" are Hitachi's internal definition codes for the FFC product shape parameters.

[0020] A first camera mounting plate 1 is arranged on the sensor induction sheet mounting plate 6, and a first camera 2 for shooting the material tape is connected with bolts on the first camera mounting plate 1. Since the sensor induction sheet mounting plate 6 can move along the length direction of the single-axis slide table 4 through the lead screw u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com