Side wall air inlet/outlet infrared air sensor

A gas sensor and sensor technology, applied in the fields of instruments, scientific instruments, color/spectral characteristic measurement, etc., can solve the problems affecting the popularization and application of infrared gas sensors, difficult engineering realization, long response time, etc. The effect of time reduction and response time reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

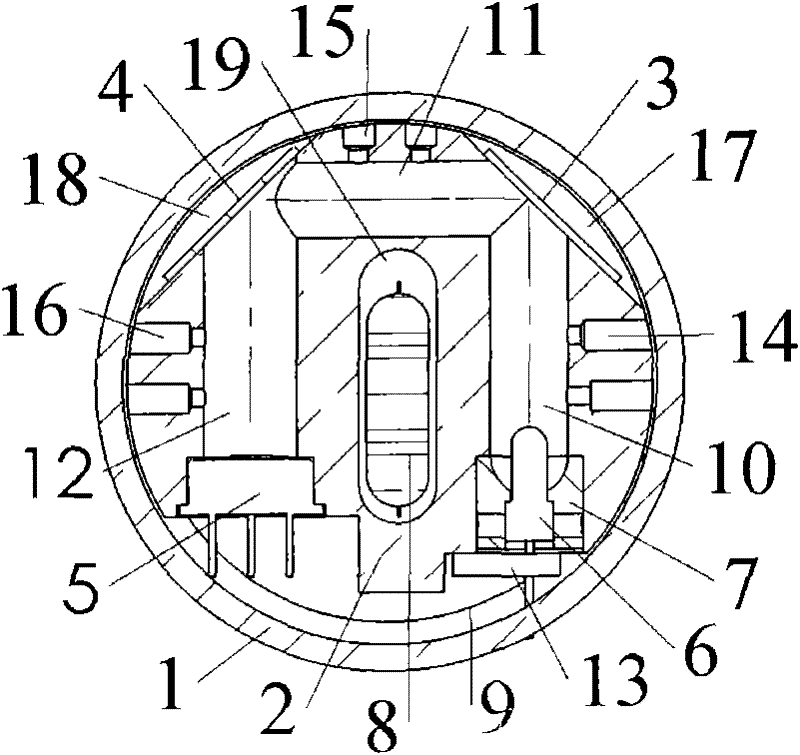

[0032] figure 1 It shows the structure inside the sensitive head of the infrared gas sensor with gas inlet / outlet through the side wall provided by the embodiment of the present invention. Dust cover 1 is a cylinder with an outer diameter of 40mm, an inner diameter of 34.5mm, and a height of 18mm made by sintering 60-80 mesh stainless steel powder and a stainless steel shell; dust cover 1 is embedded with a cylinder with a diameter of 34mm and a height of 16mm Shaped brass cavity 2; the right end of the cavity 2 is provided with a first through hole 10 at the right end with a diameter of 5mm, and a condenser lens 7 is arranged at the rear end of the first through hole 10 at the right end, and an infrared light source 6 is installed in the condenser lens 7, and the first through hole at the right end 10 The side wall is provided with at least 2 ventilation holes 14 with a diameter of 1-3 mm; the front end of the cavity 2 is provided with a front end second through hole 11 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com