Attenuation phase shift mask

A technology of attenuation phase shift and mask, applied in the field of lithography, can solve the problem that the attenuation phase shift mask cannot meet the design requirements, and achieve the effect of large process window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In semiconductor processes, such as logic devices, which include both static random access (SRAM) components and random logic (Random Logic) components, when using photolithographic technology to make contact holes, the design is realized by attenuating the phase shift mask Graphic transfer.

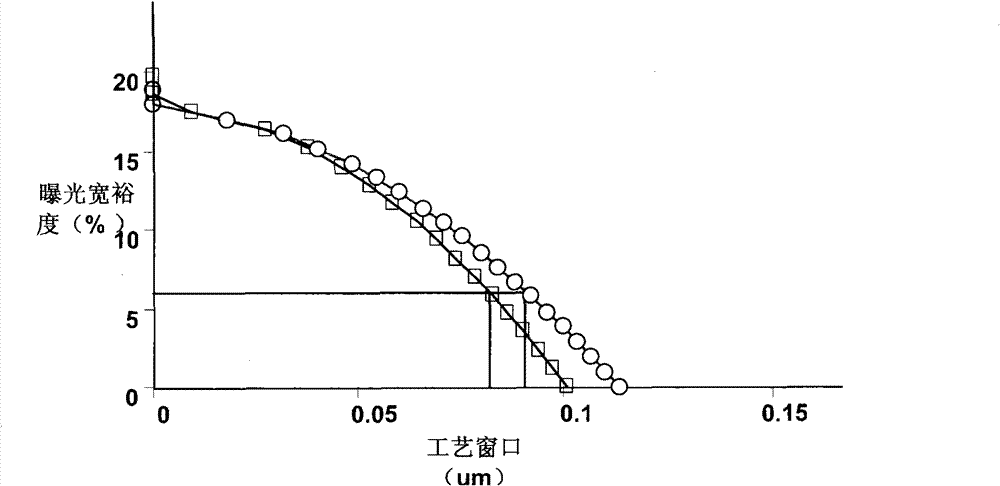

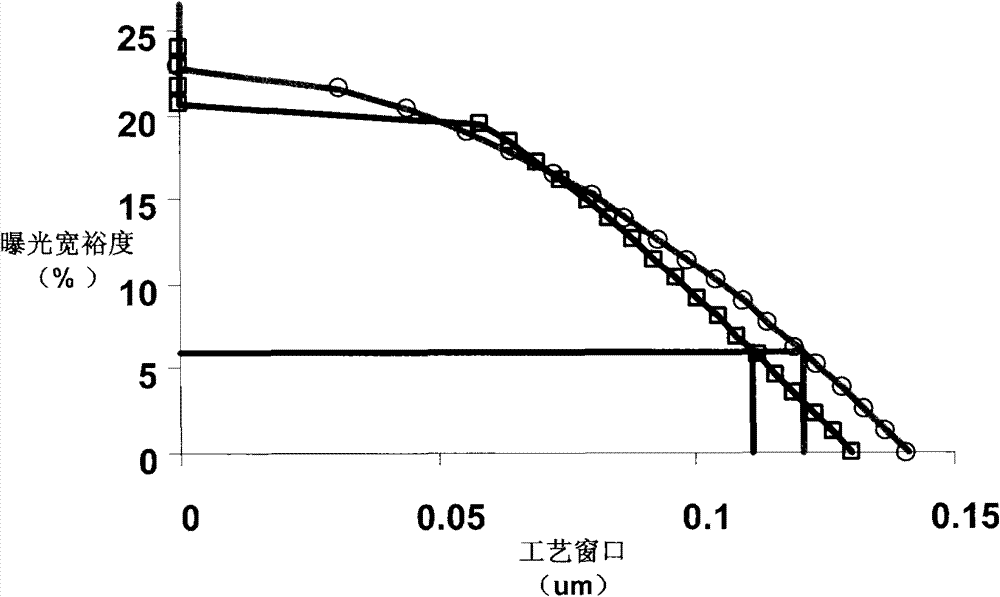

[0019] In the prior art, if an attenuated phase-shift mask with a single light transmittance is used, it will lead to a contradiction between the process window and the side lobe effect. For example, with an exposure margin of 6%, refer to figure 1 with figure 2 , when using an attenuated phase-shift mask with a light transmittance of 6%, see the curve formed by the small squares, the process window of the static random memory component is 0.082um, the process window of the random logic component is 0.11um, and when using For an attenuated phase-shift mask with a light transmittance of 12%, see the curve formed by the small circles, the process window of the static random memor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com