Anti-collision buffering device of wafer single-side polishing machine

A single-side polishing and decompression device technology, which is applied in the field of polishing machinery, can solve the problems of damaging machine equipment, breaking polishing discs, and destroying polished wafers, so as to buffer the impact force, prolong the service life, and ensure the polishing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

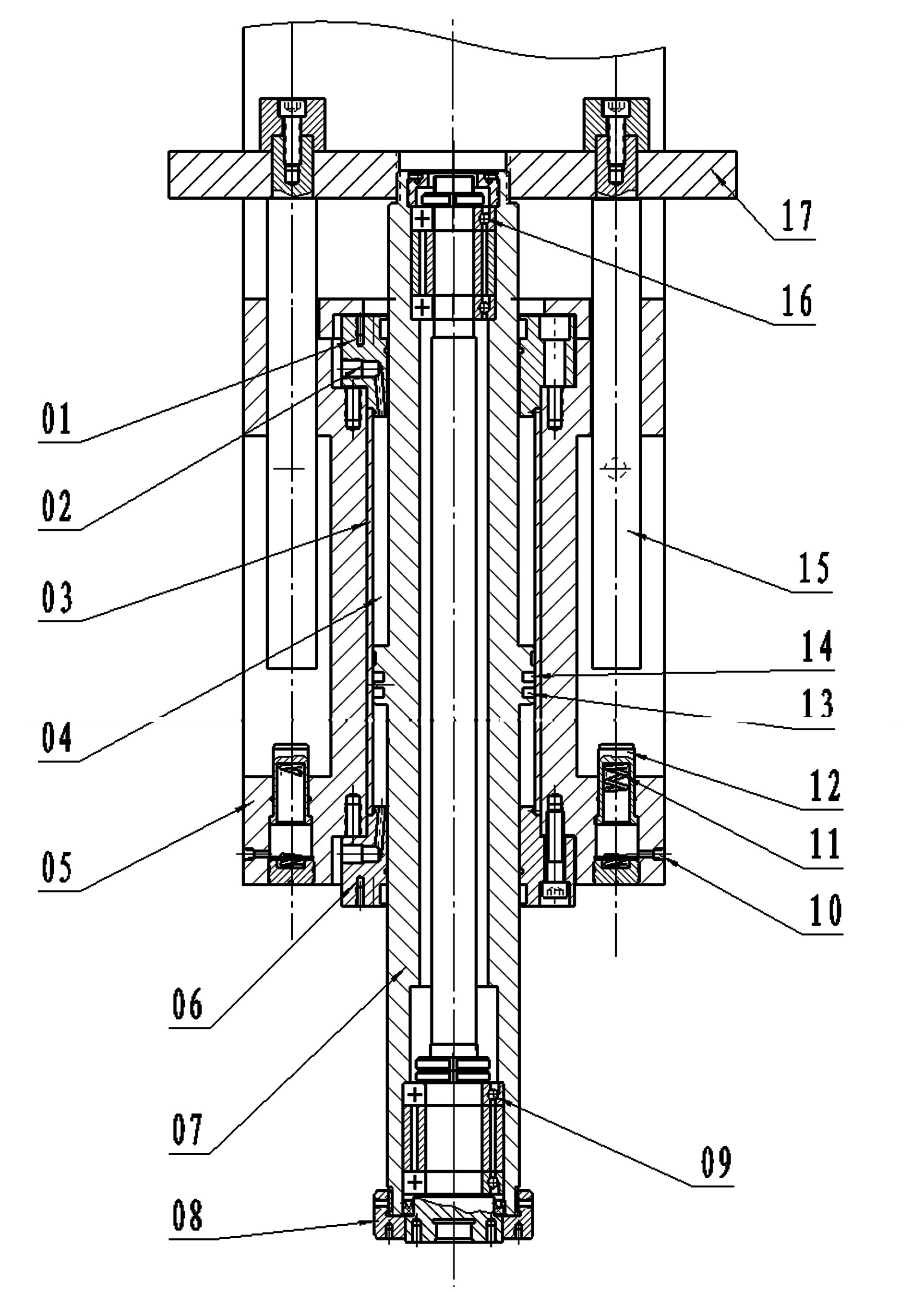

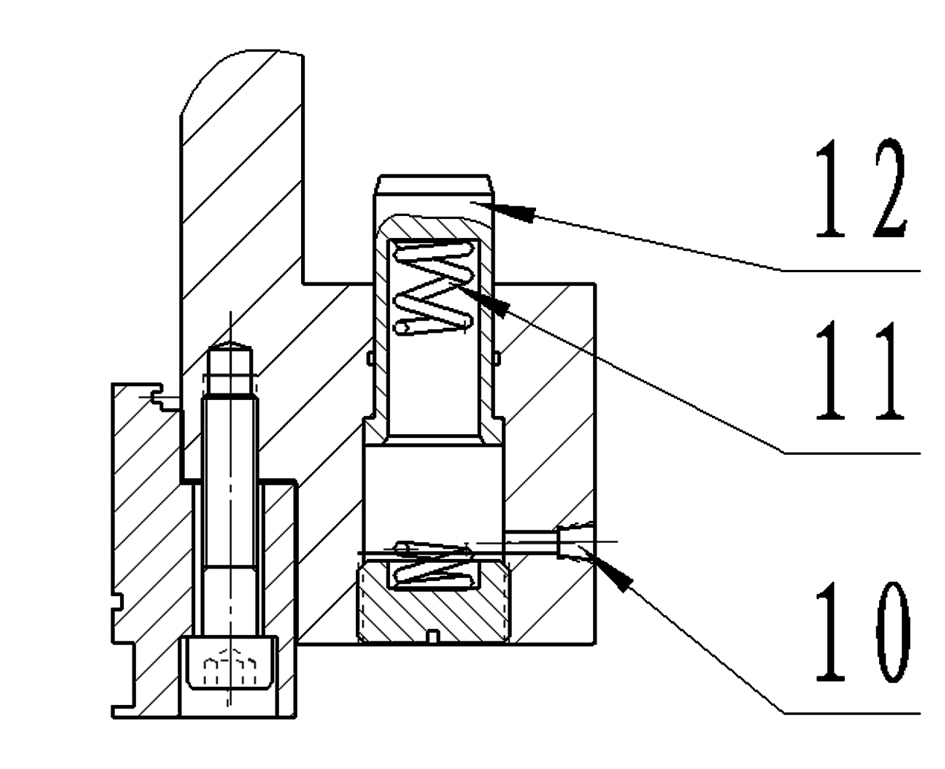

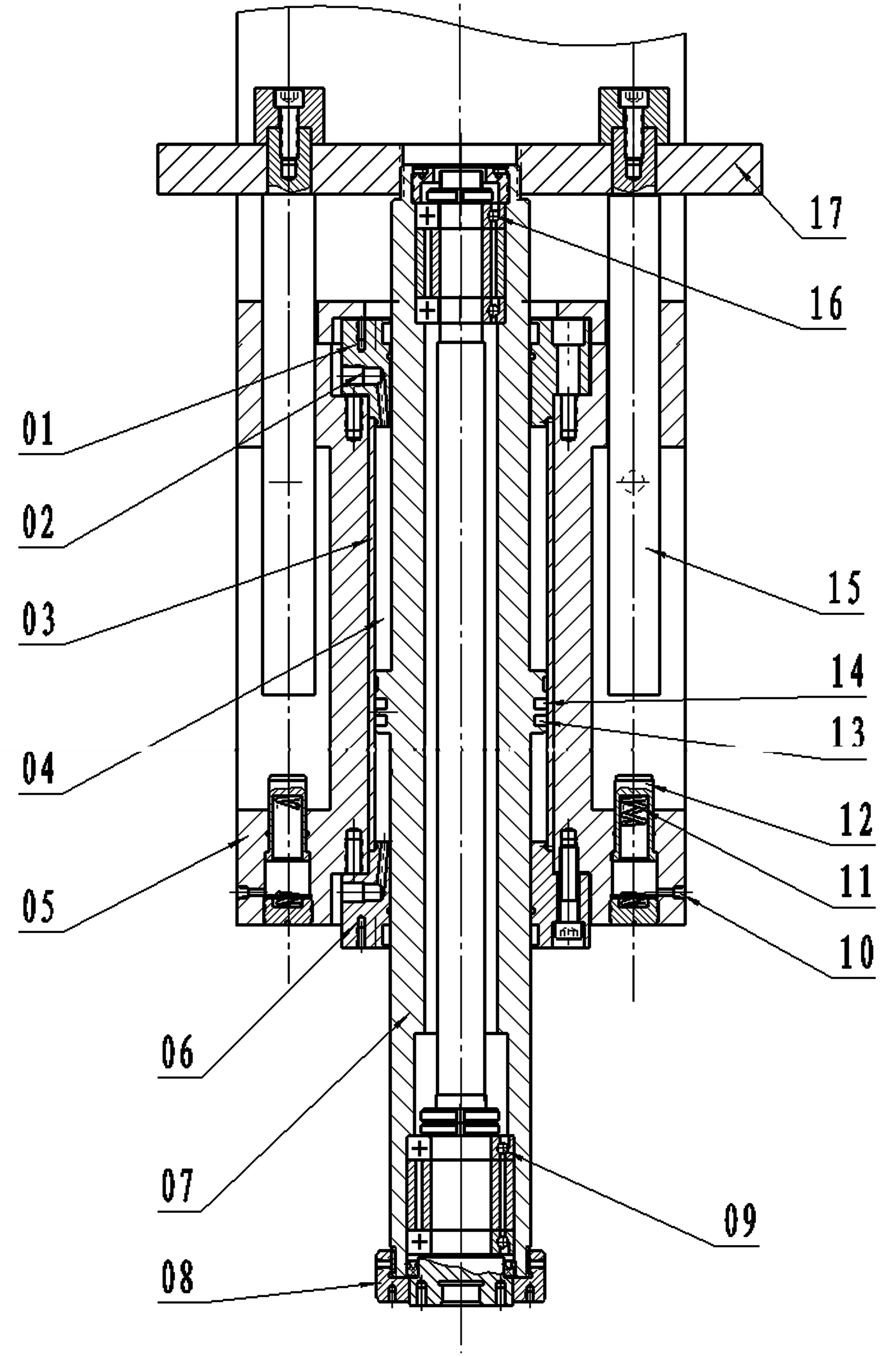

[0013] see figure 1 , 2 The rotating shaft 07 of the upper grinding disc is integrated with the piston rod of the cylinder and put into the cylinder liner 03. The upper end of the rotating shaft 07 is connected to a connecting plate 17, and two transmission rods 15 are symmetrically installed on both sides of the connecting plate 17. On the stroke of the transmission, 15 The damping oil cylinders are respectively installed at the bottom dead center, the lower cylinder body of the damping oil cylinder is directly set on the support 05 of the air cylinder, the pressure spring 11 for reset is installed in the damping oil cylinder, and the hydraulic oil interface 10 of the damping oil cylinder is connected to the oil reservoir (in the figure not pictured). The pressure spring 11 installed in the cylinder of the damping oil cylinder adopts a cylindrical helical spring, and one end is pressed against the bottom of the cylinder, and the other end is pressed against the inner hole of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com