Lower mold positioning and locking device for fire-resistant brick forming hydraulic machine mold

A technology of locking device and hydraulic press, which is applied in the direction of ceramic molding machines, auxiliary molding equipment, manufacturing tools, etc., can solve the problems of low degree of automation, uneven pressure on the lower mold, and weak locking, etc., so as to reduce labor intensity, Ensure fast positioning and locking, and improve productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

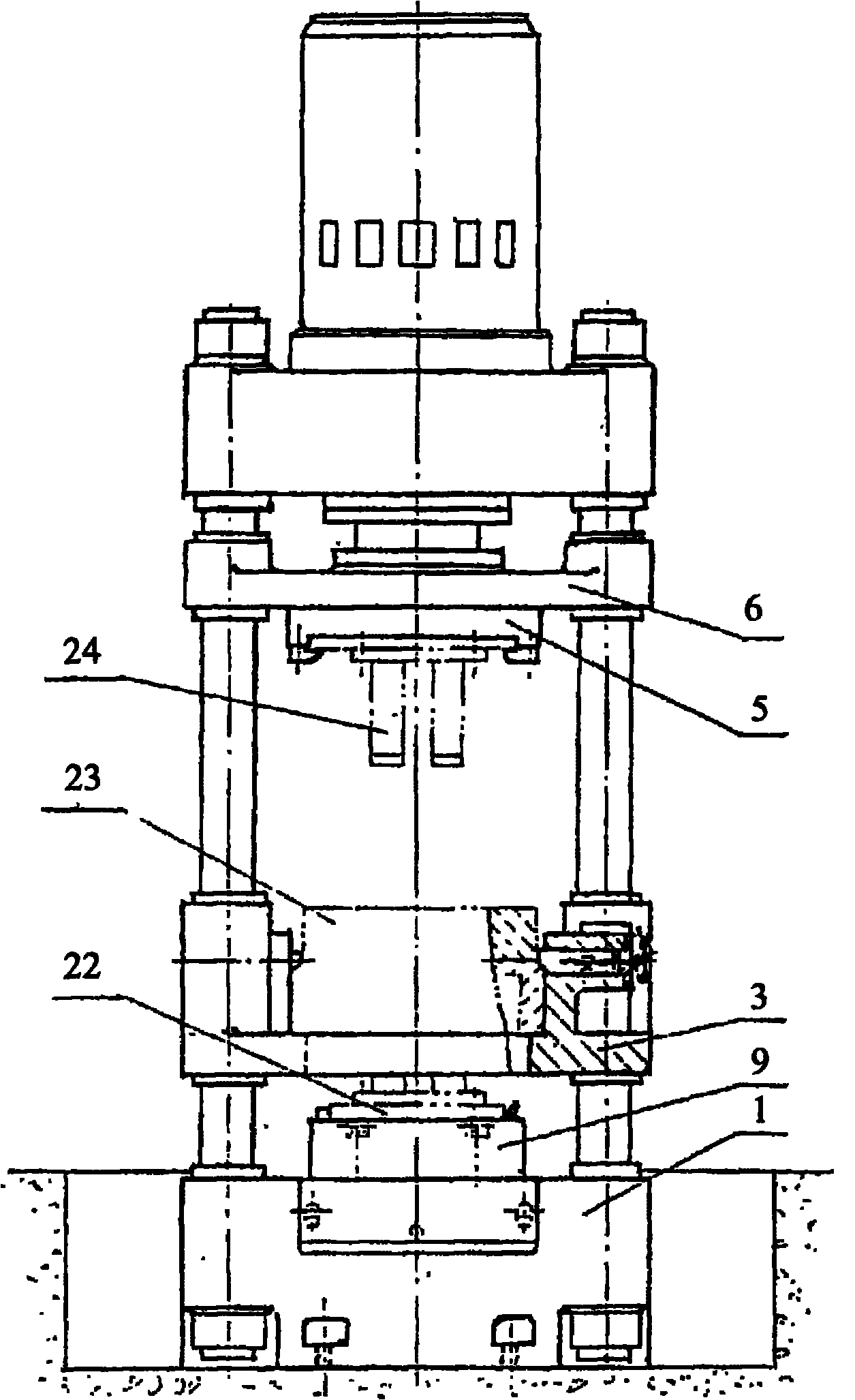

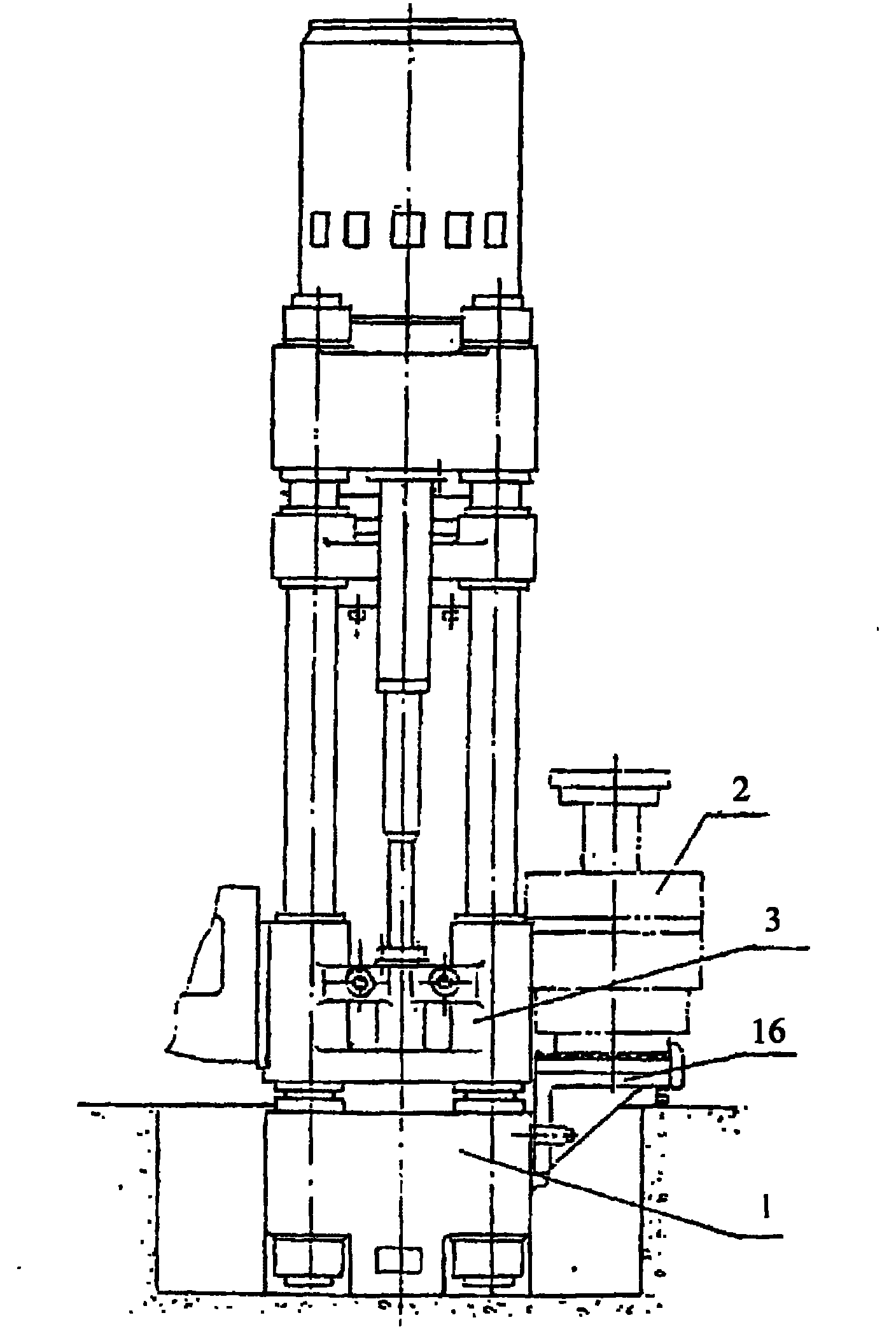

[0027] The present invention will be described in more detail below in conjunction with the accompanying drawings.

[0028] Best practice:

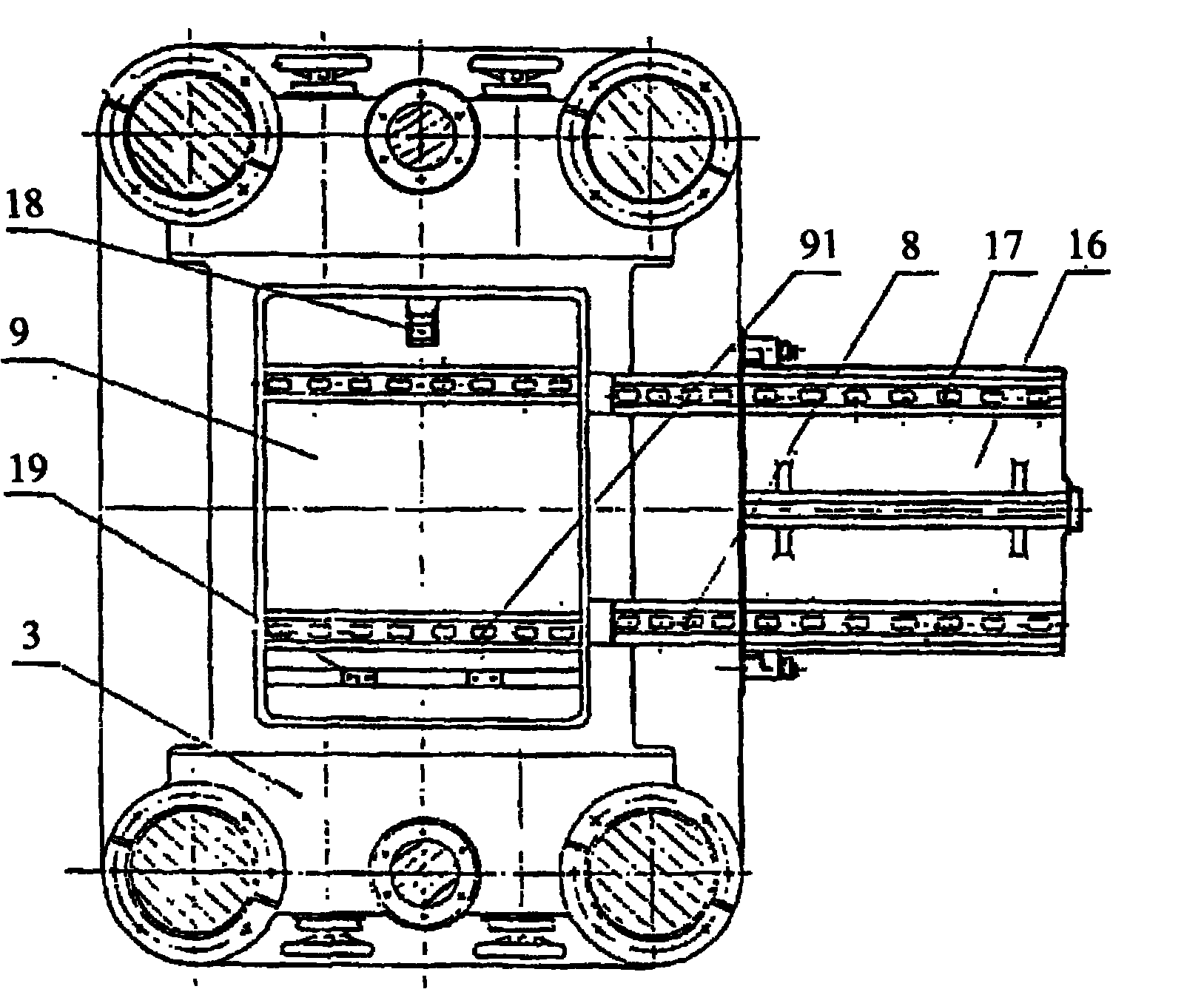

[0029] refer to Figure 4 , 5 , 6. The lateral positioning device is composed of a T-shaped bar 14 extending end-wise on the lower mold base 9 and a corresponding T-shaped groove. The ups and downs raceway 91 is located on the top of the T-shaped bar 14. The upper rolling surface composed of a plurality of rollers on the T-shaped bar 14 is composed of a T-shaped groove 13 connected to the sliding sleeve of the T-shaped bar 14 at the corresponding part of the bottom of the mold fixing plate 21, and the bottom of the T-shaped bar 14 is connected to the oil cylinder 15. Piston connection. T-shaped bars and grooves can be used as lateral positioning devices, and the piston 15 can drive the ups and downs raceway 91 and the T-shaped bar 14 to move up and down, thereby not only realizing the ups and downs of the ups and downs raceway 91, but ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com