Automatic punching pile driver

A technology of automatic punching and pile driving, applied in percussion drilling, reciprocating drilling rigs, drilling equipment and methods, etc., can solve the problems of easily damaged machines, impact, waste of human strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

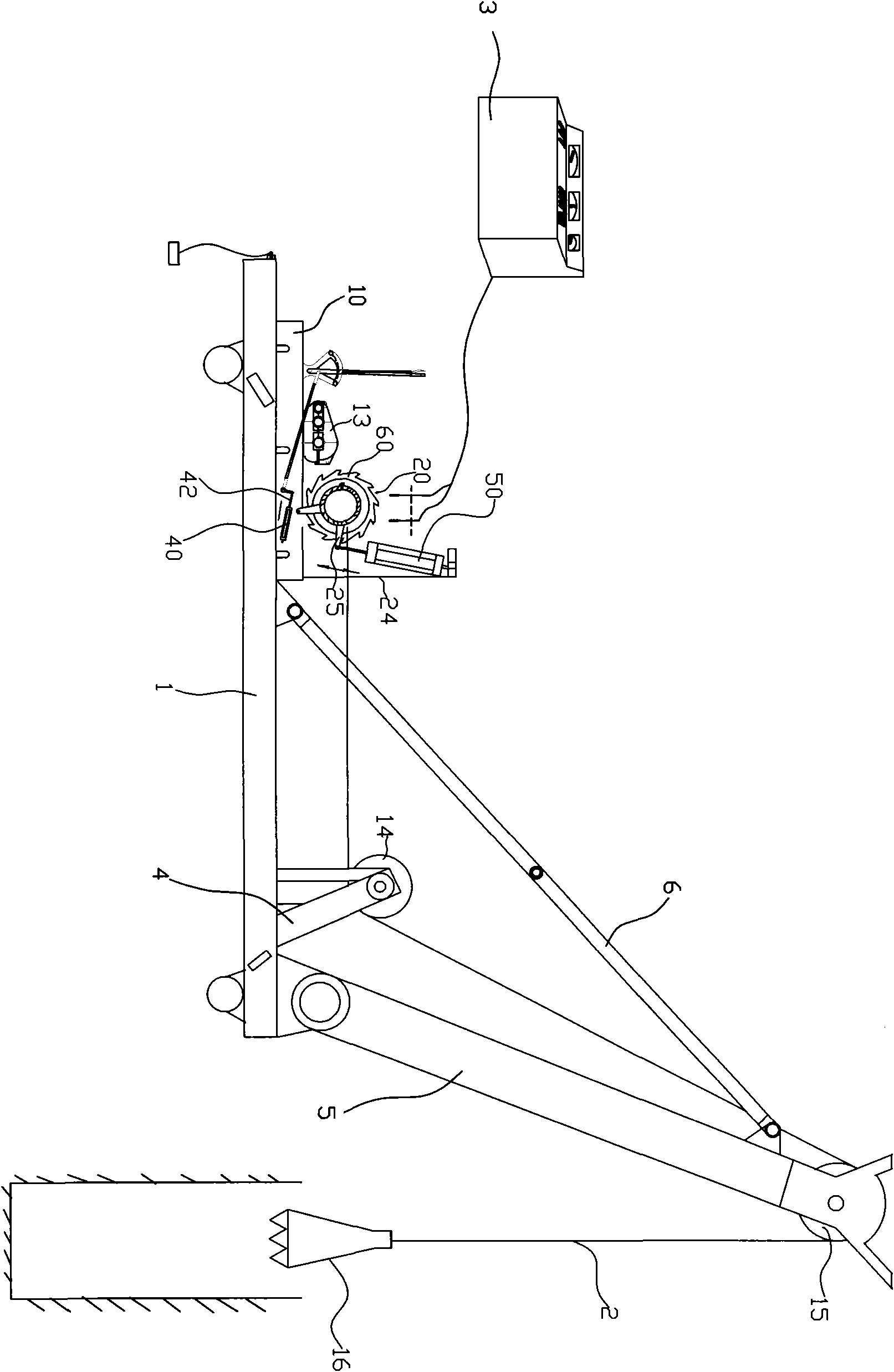

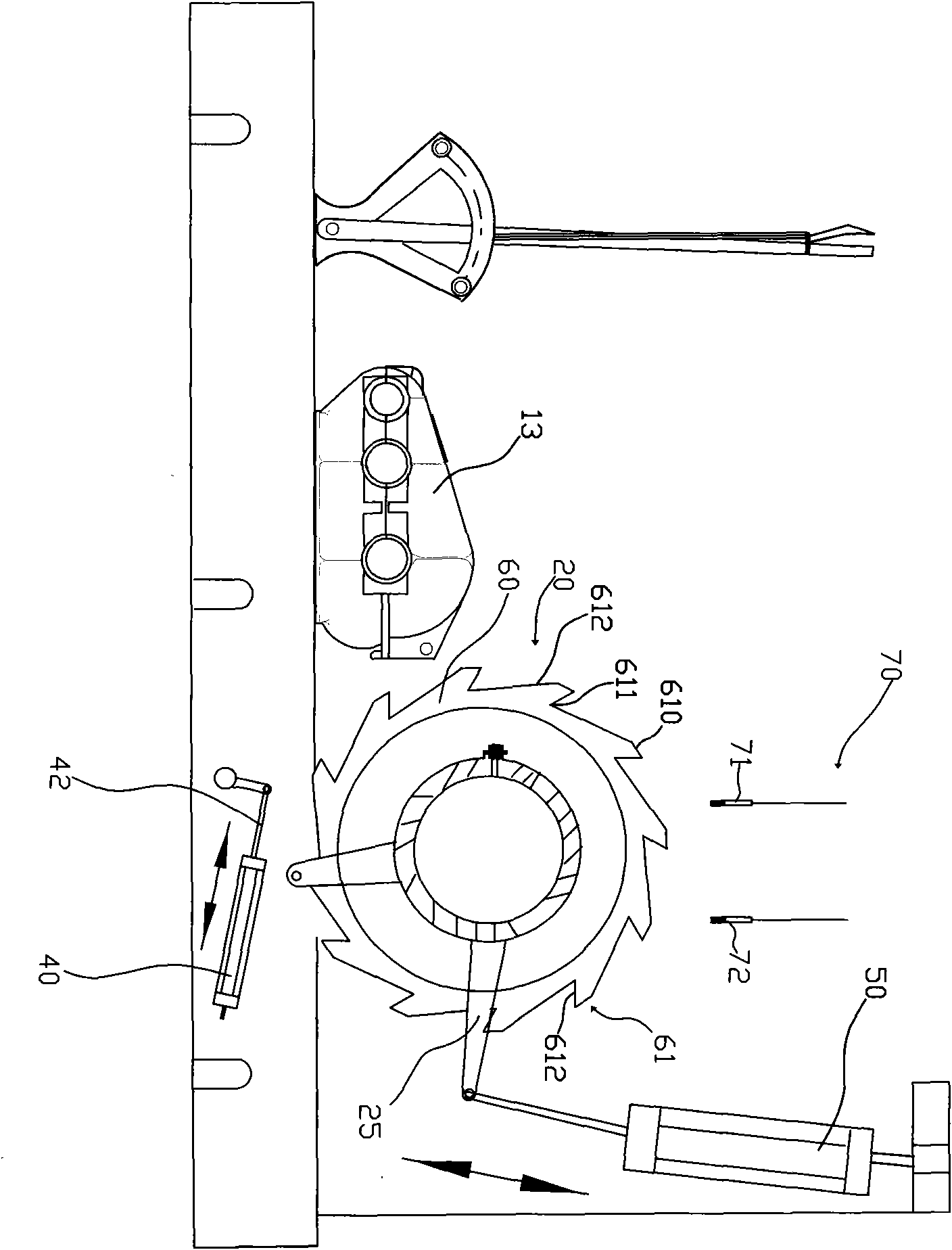

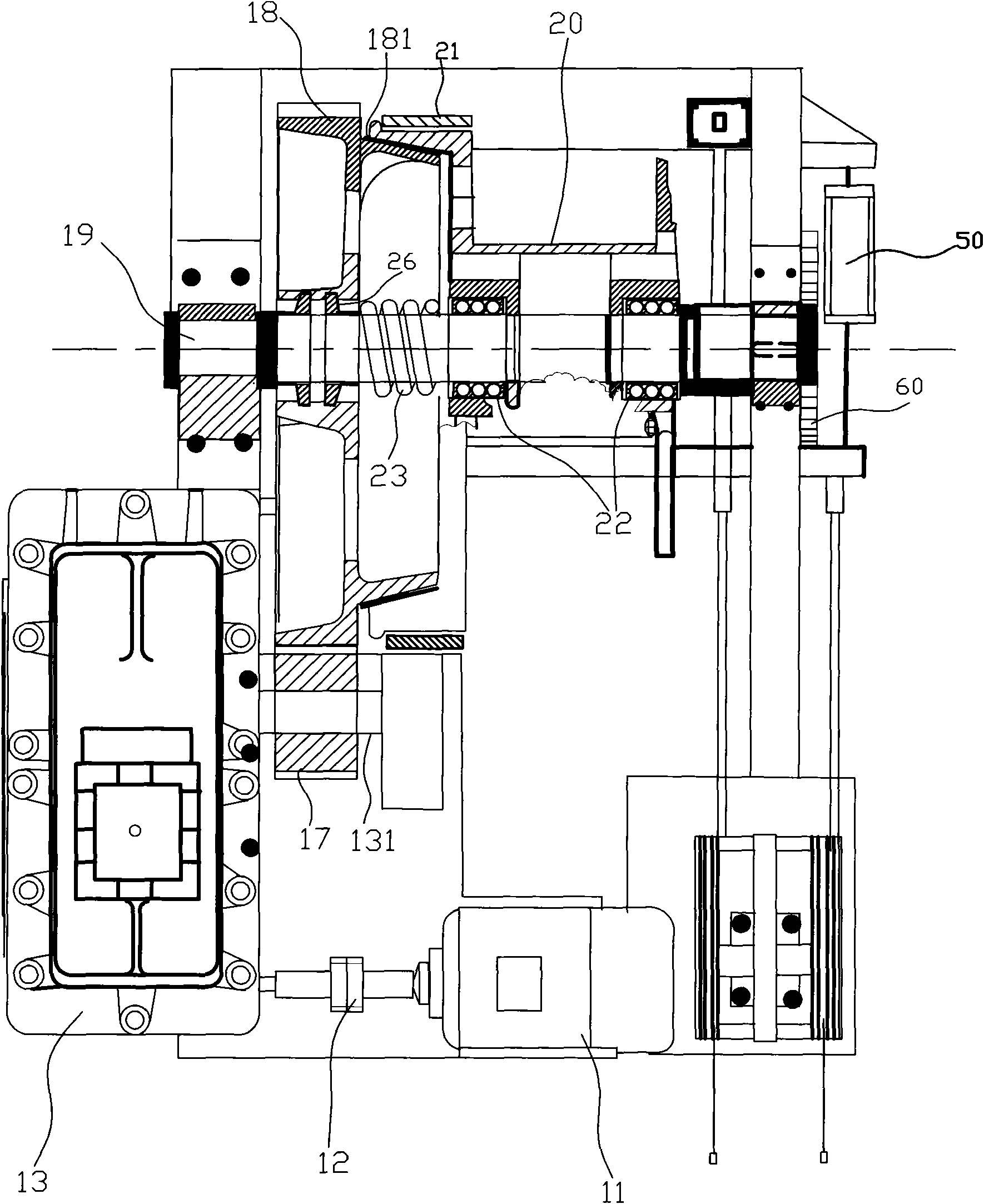

[0032] Such as Figure 1 to Figure 6 Shown, the present invention comprises the support 10 that is installed on the frame 1 when working, motor 11, reduction box 13, fixed shaft 19, reel 20, the first fixed pulley 14, the second fixed pulley 15, a wire rope 2 and weight 16, of which:

[0033] The frame 1 is also provided with a first support 4, a second support 5 and a pull rod 6. The height of the first support 4 is equivalent to or slightly higher than the height of the reel 20 and is mounted on the frame. 1 near the front end, the first fixed pulley 14 is installed on the first support; The inclination direction between the racks 1 is connected by a pull rod 6, and a second fixed pulley 15 is installed on the top of the second bracket 5;

[0034] Described electric motor 11 is installed on the machine base 10 and provides power for punch pile driver of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com