Iron base, ironing device, and method for manufacturing an iron base

A technology for irons and iron tables, which is applied in the field of iron soles, can solve complex and expensive problems, and achieve the effects of rationalized manufacturing process, simple manufacturing, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

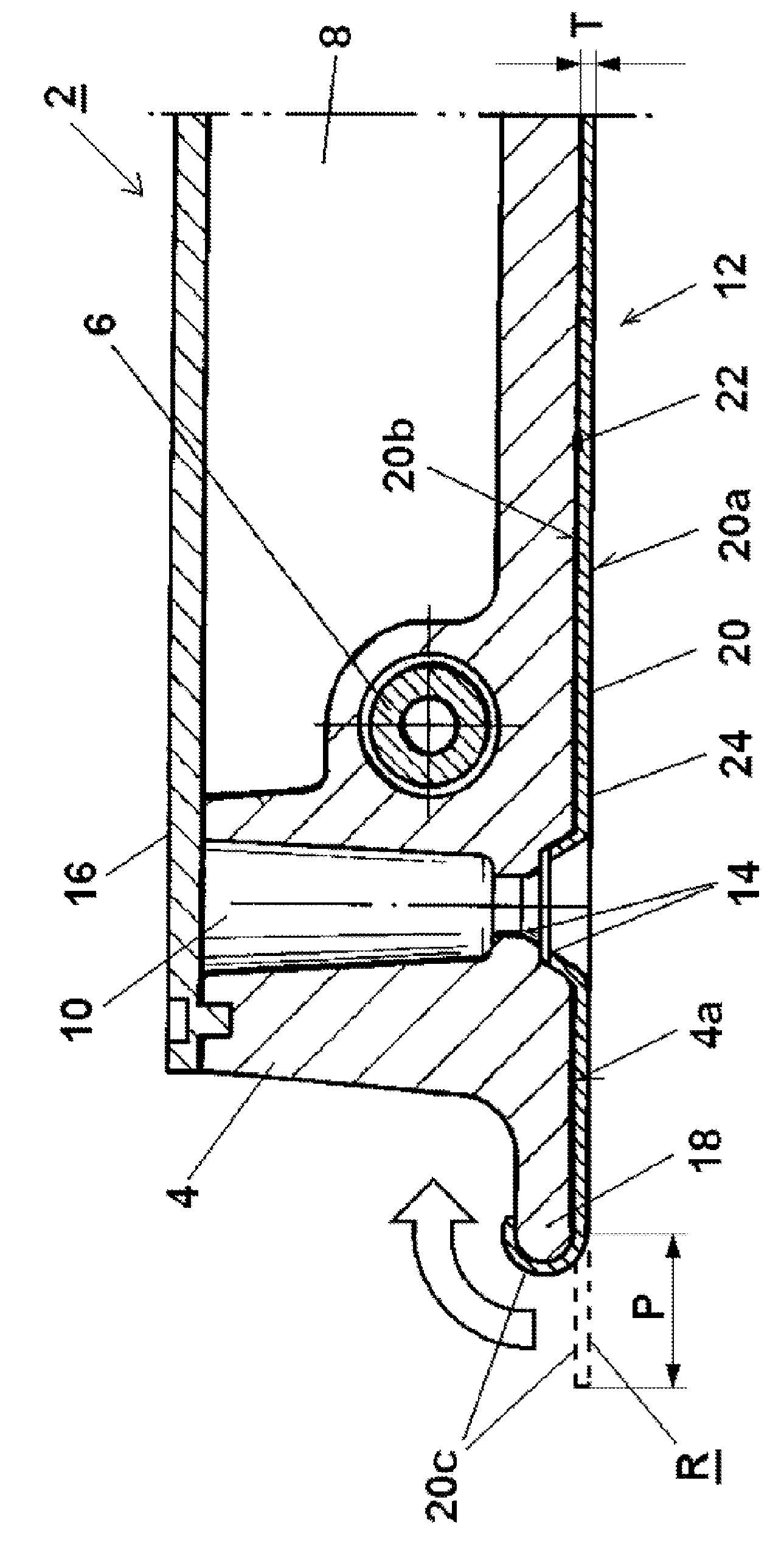

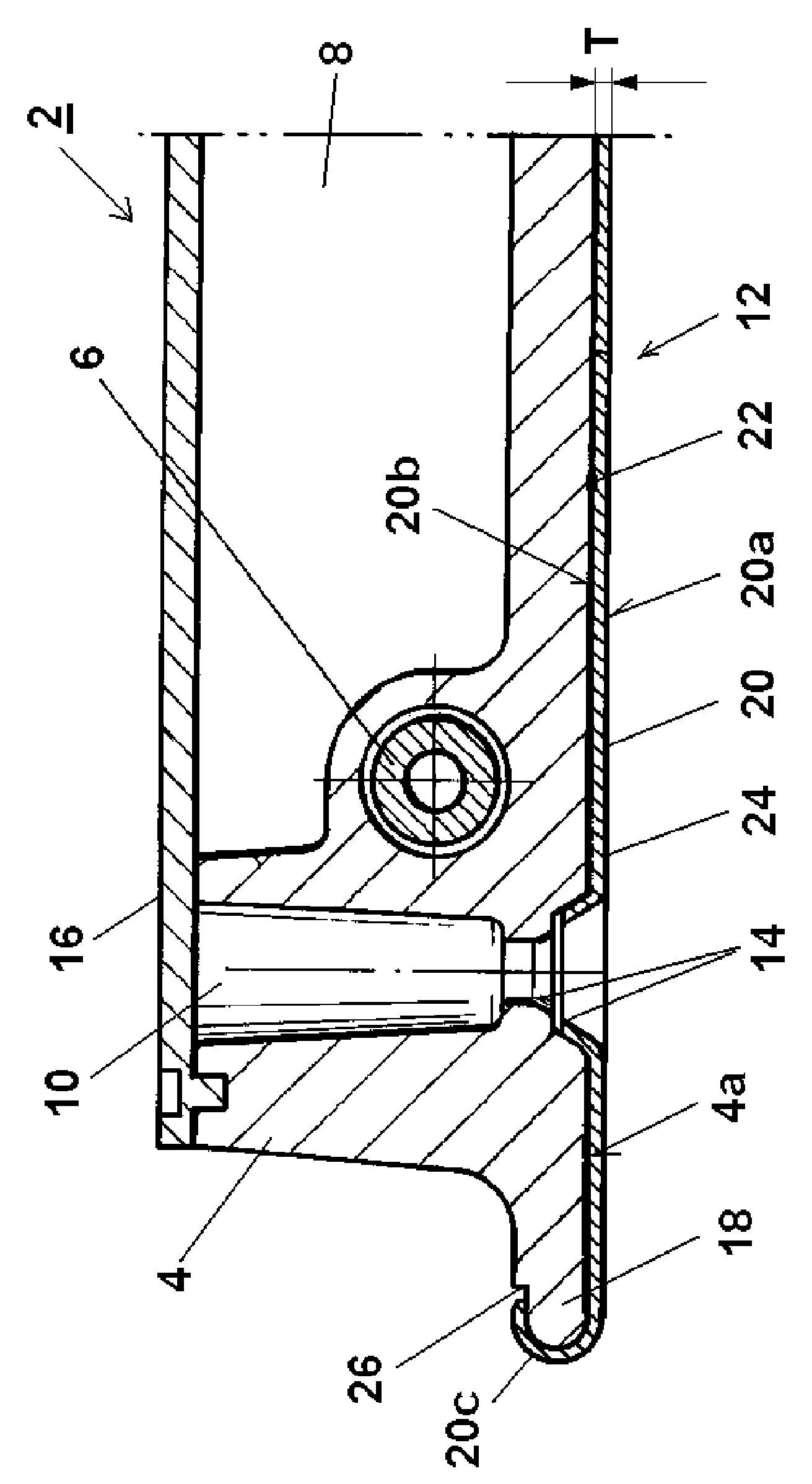

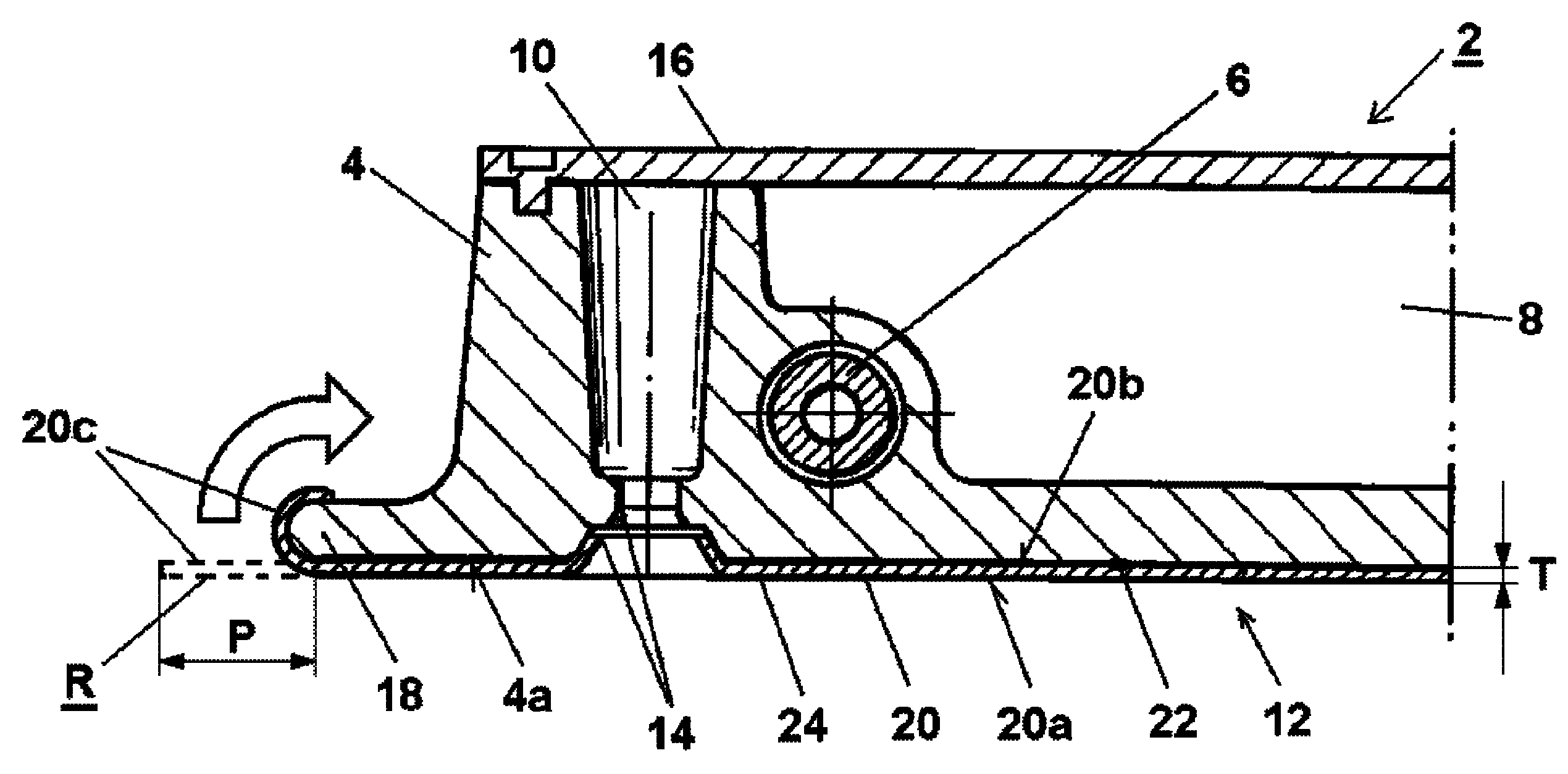

[0021] exist figure 1 A first exemplary embodiment of an iron sole 2 according to the invention of an ironing device according to the invention (here: an electric steam iron) is schematically shown in FIG. Furthermore, the iron sole 2 comprises a base body 4 made of cast aluminum with integrated electrical heating means 6 , a steam generation chamber 8 , steam distribution channels 10 and a sole plate 12 made of aluminum arranged on the base body 4 and is connected to the base body. The base body 4 and the bottom plate 12 have mutually identical steam outlets 14 . The base body 4 can be closed at the top by a cover 16 . as from figure 1 It can also be seen in the figure that the base body 4 has a lower circumferential web-shaped side edge 18 which has rounded edges.

[0022] The base plate 12 is made of a thin aluminum plate 20 which in the example here has a thickness T of 0.4 mm and is made of an aluminum-plastic alloy. In principle, the thickness of the aluminum plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com