Orthotropic plate U-shaped rib angle weld joint double-side welding technique

An orthotropic plate, fillet weld technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., to achieve the effect of unique concept, strong practicability, stable tracking and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

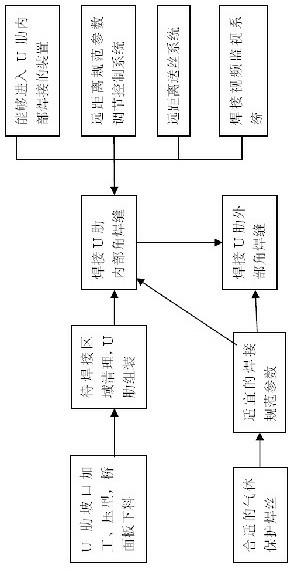

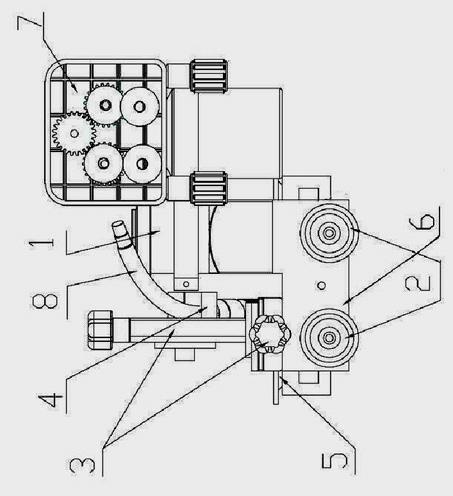

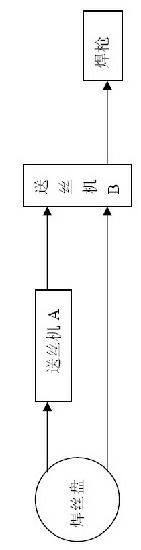

[0046] exist figure 1 The process block diagram of the present invention is given in , the first process is U-shaped rib groove processing, pressing, and bridge deck blanking, including: U-shaped ribs are processed with steel plates after cutting, and pressed to become U-shaped ribs ; The bridge deck is blanked with steel plates. The second process is to clean up the area to be welded and assemble the U-shaped ribs, including: clean and polish the U-shaped ribs and the welding hazards in the area to be welded on the bridge deck, and then perform U-shaped rib assembly according to the U-shaped rib assembly positioning line on the bridge deck. Rib assembly and tack welding. The third process is to weld the inner fillet weld of the U-shaped rib, and weld a fillet weld on the back of the U-shaped rib fillet weld. Devices, long-distance specification parameter adjustment control system, long-distance wire feeding system, welding video monitoring system measures. The fourth proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com