Components direction regulating mechanism for ball pen assembly and assembly system and method

A technology for adjusting mechanisms and parts, applied in the repair and printing of ballpoint pens and ink pens, and can solve the problems of high cost, complex machine structure, and single production variety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0127] The orientation adjustment mechanism, assembly system and assembly method of the ballpoint pen assembly parts of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

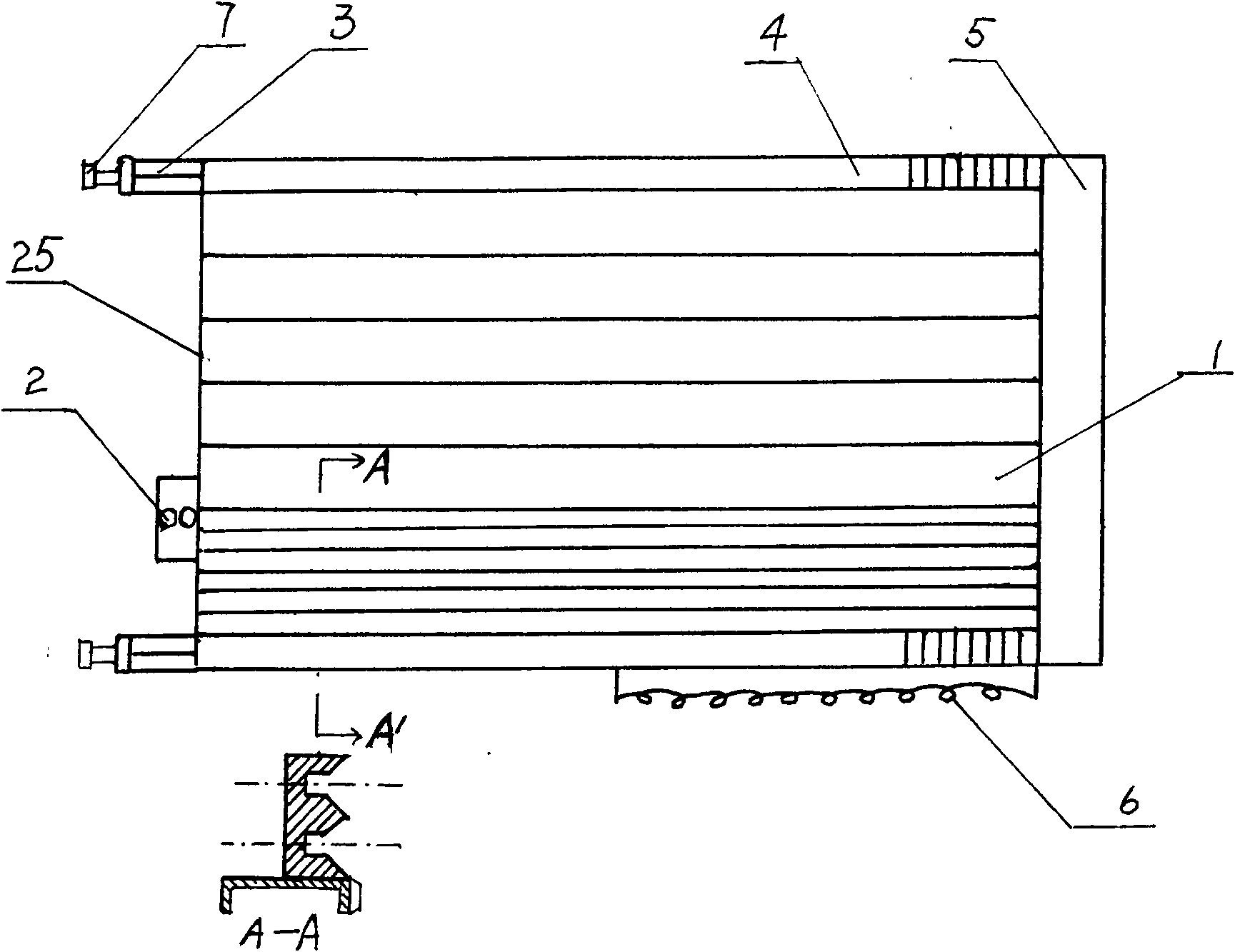

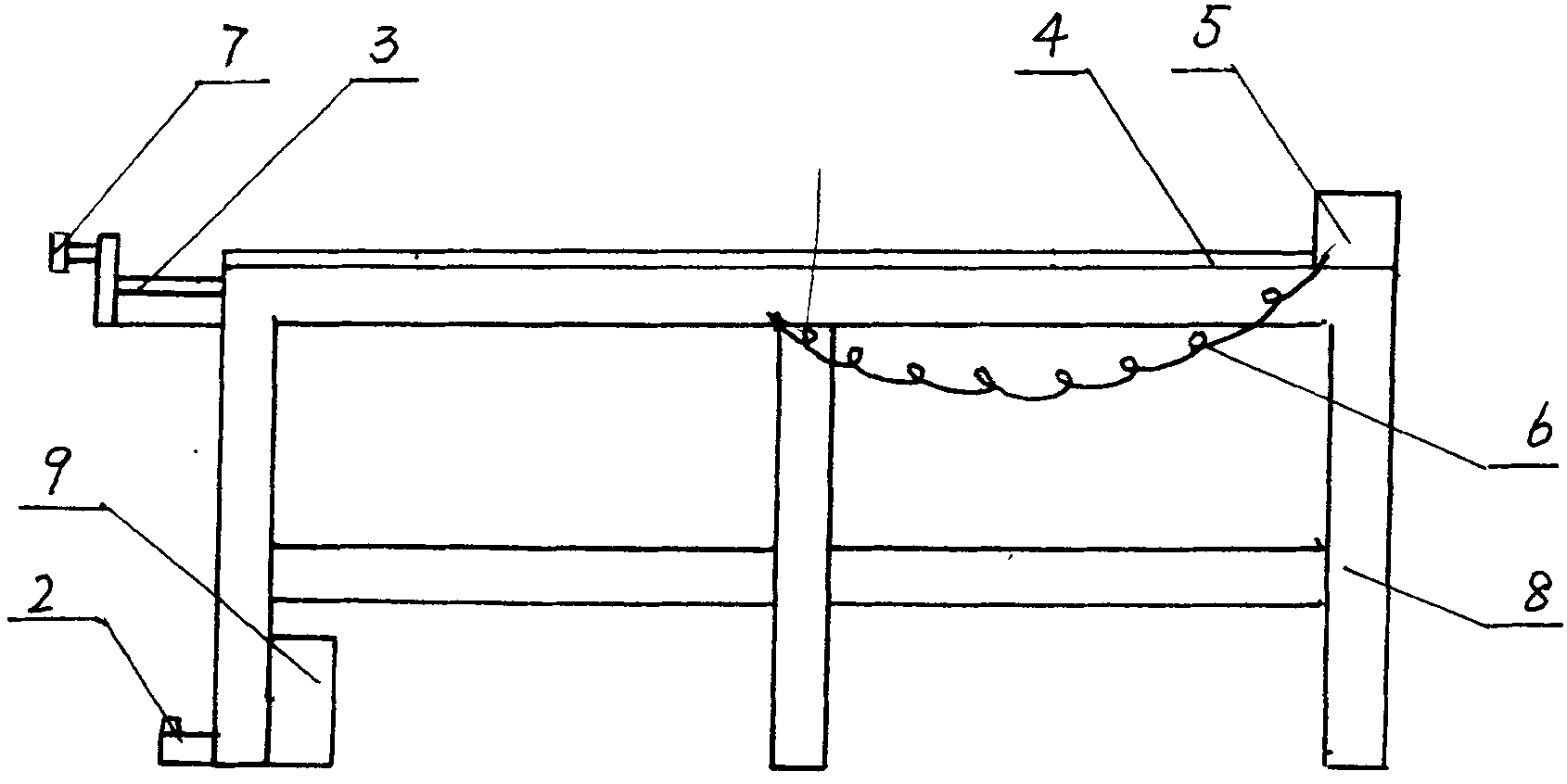

[0128] Such as figure 1 , figure 2 As shown, the ballpoint pen assembly parts orientation adjustment mechanism includes a flow channel plate 1 with a plurality of flow channels. The component moves along the flow channel plate 1 to the rear end of the flow channel plate 1. The writing pusher 5 moves along the rack track 4 under the control of the control unit. There is also a receiver that is arranged on the outlet end 25 of the flow channel plate 1 for receiving the parts of the ballpoint pen. The launder face where several launders mesh.

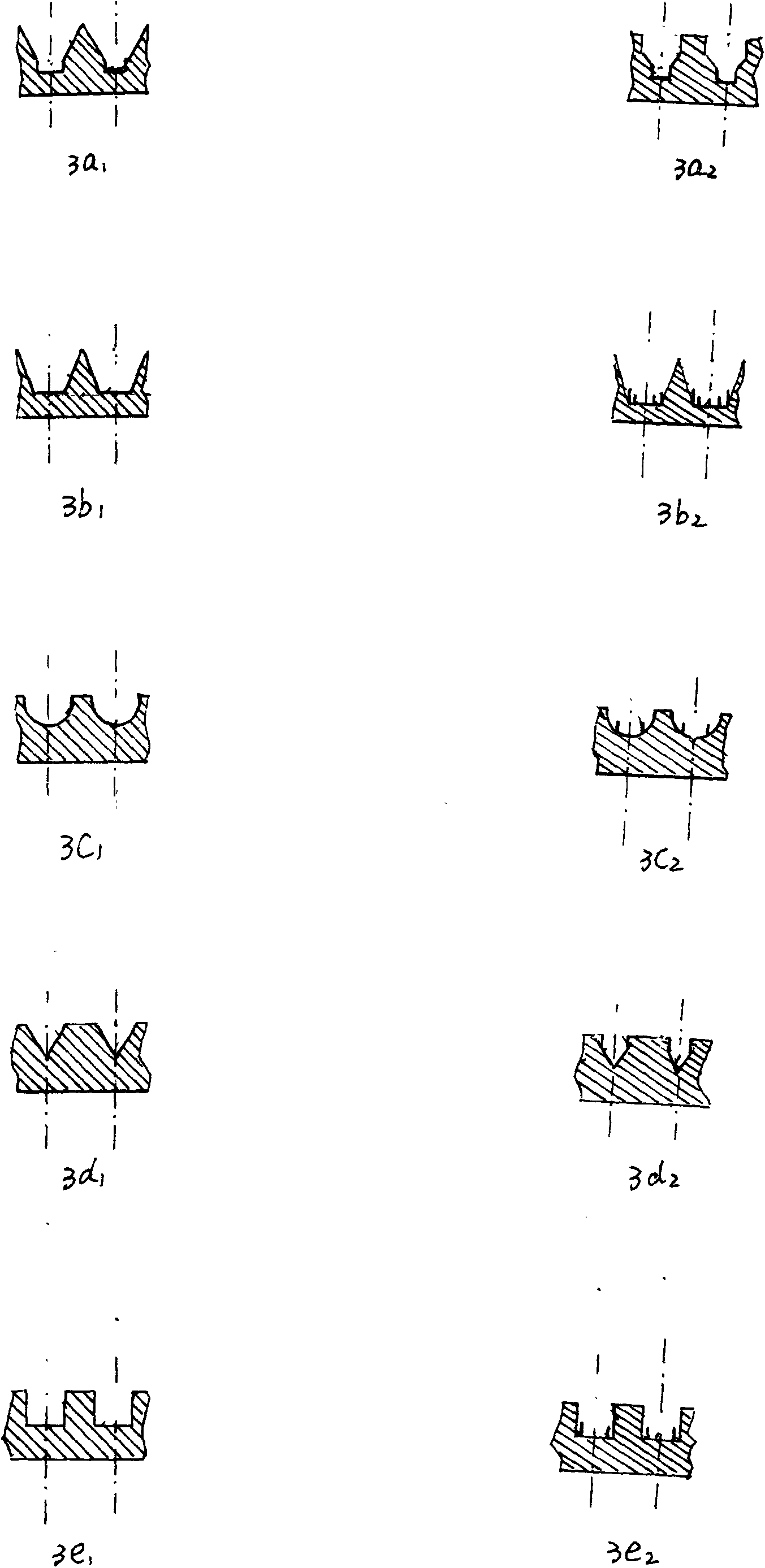

[0129] The launder on the launder plate 1 is a composite launder such as image 3 a1 and image 3 a2, trapezoidal trough such as image 3 b1 and image 3 b2, U-shaped trough such as image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com