Filling process and product of yellow wine Tetra Pak packages

A technology of Tetra Pak and rice wine, which is applied in the field of Tetra Pak rice wine packaging technology and products, can solve the problems of easy breakage in transportation and carrying, bulky packaging materials, and influence on product taste, and achieve long product shelf life, small packaging volume and weight , the effect of reducing the change in taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Rice wine is an acidic liquid with a pH of about 3 to 5, and its main component, alcohol, is easily volatilized during high-temperature sterilization. By adjusting the sterilization temperature and time, the invention enables the Tetra Pak filling process to be applied to the rice wine filling, ensures the sterilization effect and minimizes the volatilization of alcohol, and the packaging can withstand the long-term storage of the acidic liquid rice wine.

[0014] Specifically, the present invention adopts the following parameters: sterilize instantaneously at a temperature of 100°C to 130°C, and the sterilization time is controlled at 3 to 8 seconds. box.

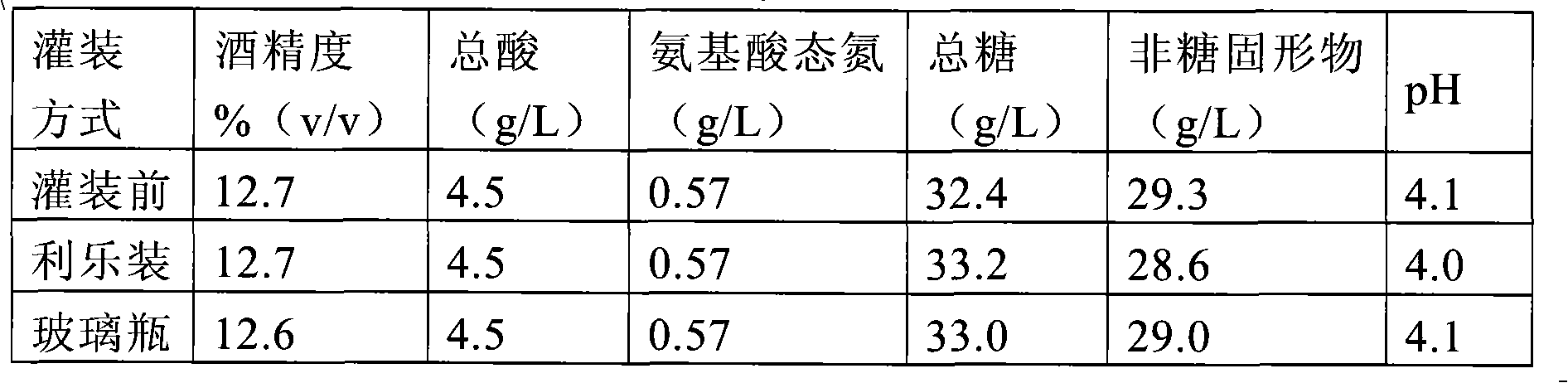

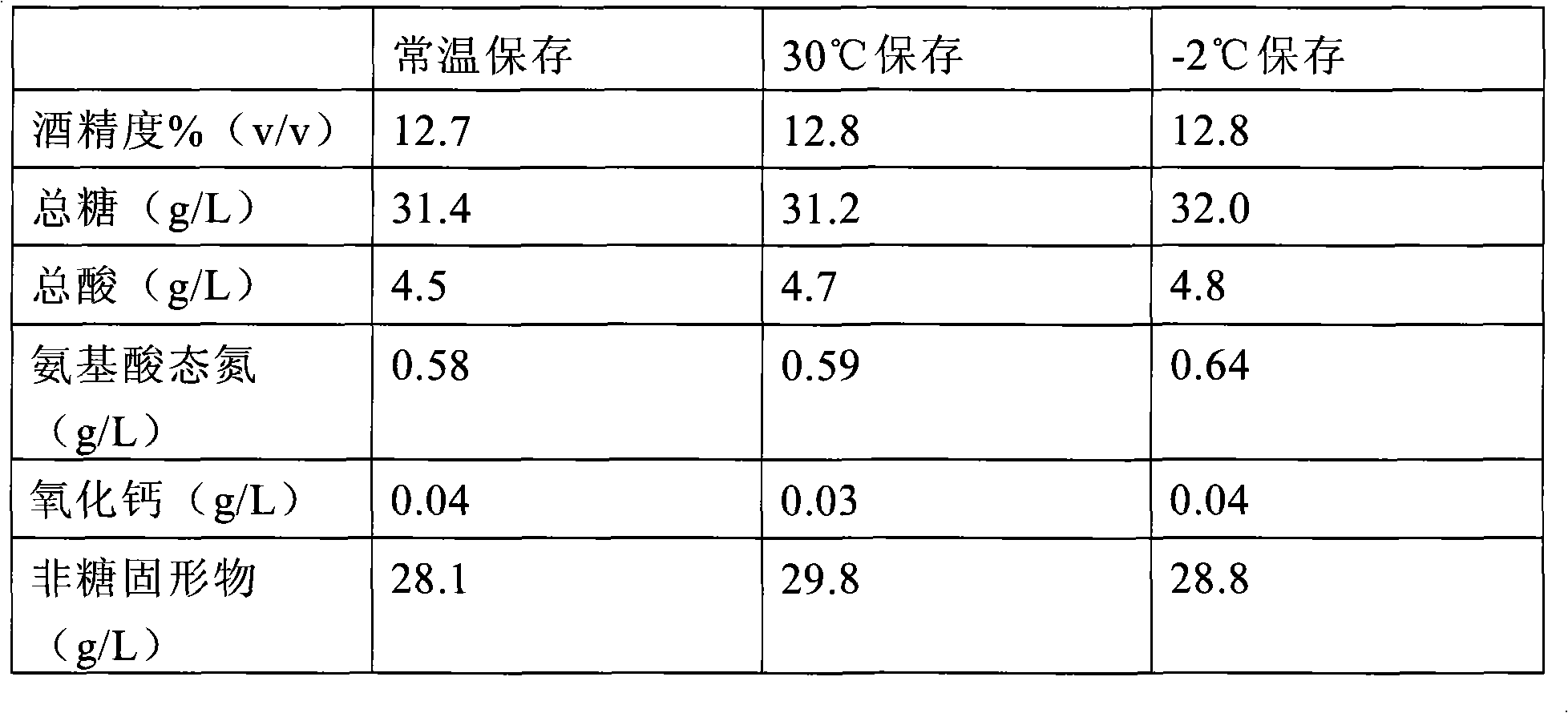

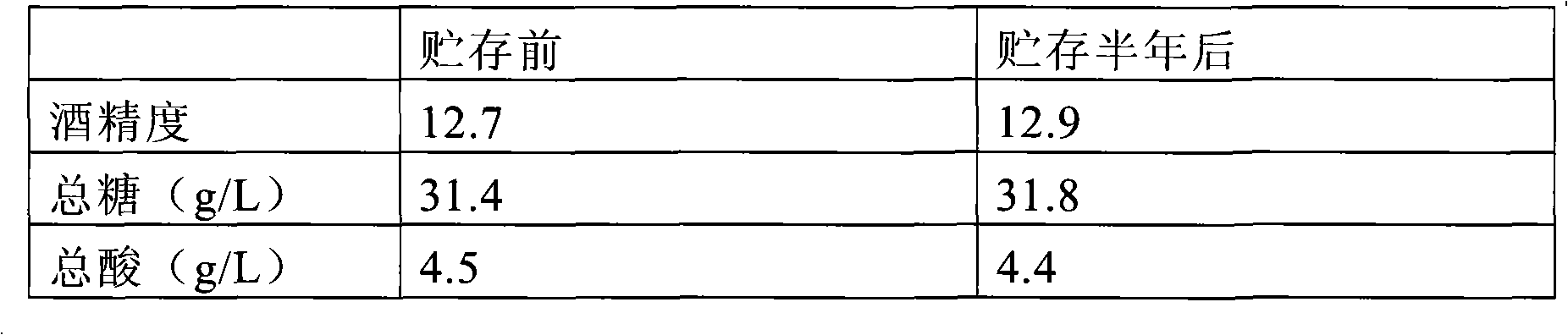

[0015] The above process parameters can minimize the volatilization of alcohol during the instantaneous high temperature process, while ensuring the satisfaction of the sterilization effect, physical and chemical indicators and taste, so that the physical and chemical indicators and taste of the product are consiste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com