Excavating drilling machine

A technology for excavating drilling rigs and drill bits, which is applied in the direction of drill bits, earthwork drilling, drilling equipment, etc. It can solve the problems of large rotary drilling rigs, low hole forming efficiency, landslides, etc., and achieves high site adaptability, improved stability, The effect of reducing flatness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further explain the technical means and effects that the present invention takes to achieve the predetermined invention purpose, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the excavation drilling rig proposed according to the present invention are as follows: The details are as follows.

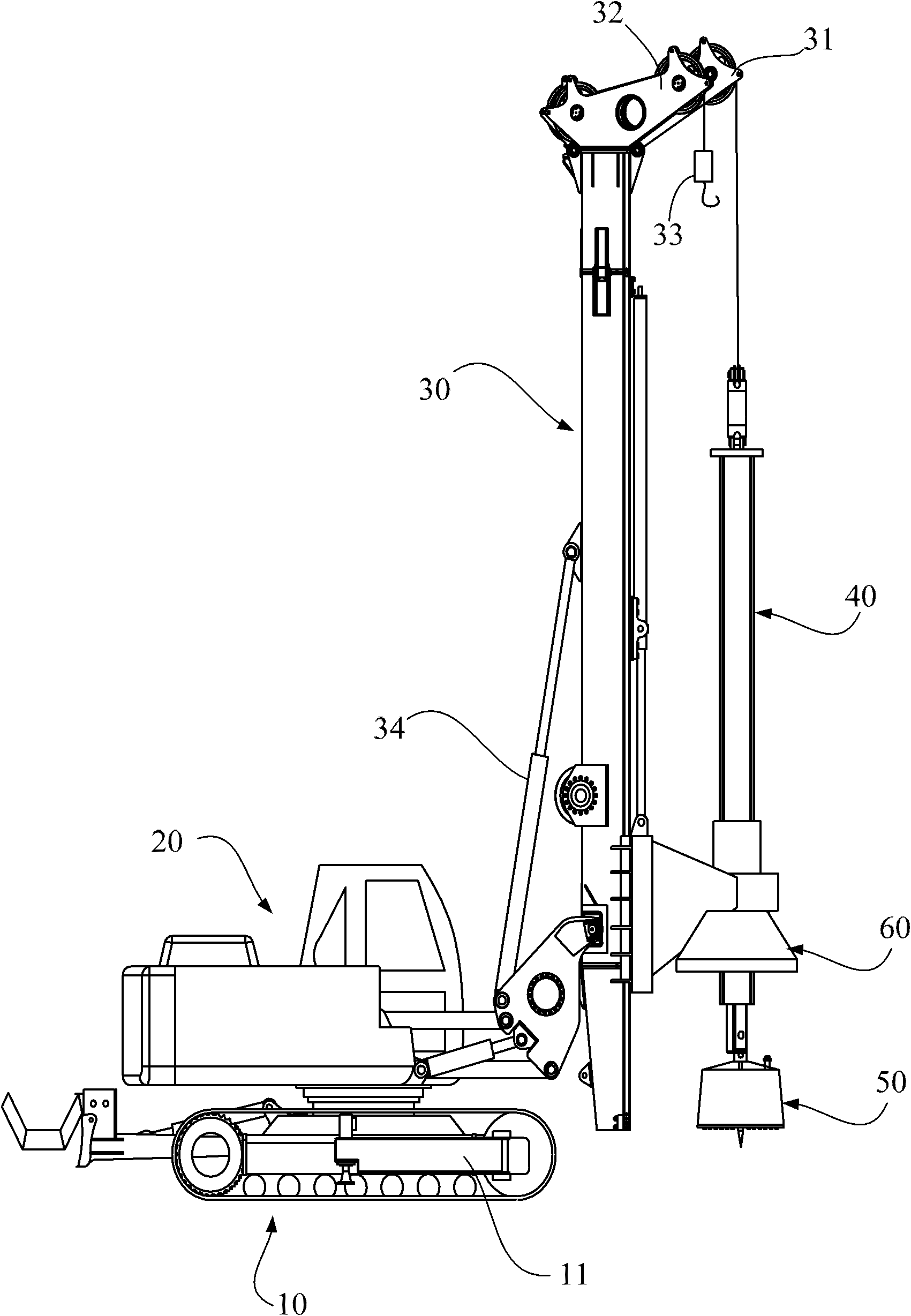

[0021] see figure 1 As shown, the excavation drilling rig of the preferred embodiment of the present invention mainly includes: chassis 10, upper car 20, mast 30, drill rod 40 and drill bit, upper car 20 is provided with hydraulic system and electric control system. The chassis 10 of the digging rig of the present invention adopts the chassis of a small excavator, preferably adopts the chassis of a Yuchai YC135 type excavator. The technical parameters of the chassis are shown in Table 1.

[0022] Table 1 Main technical parameters of Yuchai YC135 excavator chassis

[0023] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com