Eccentric shaft control system of complete-variable air valve lift mechanism

A valve lift and control system technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of complex structure and low reliability of the eccentric shaft control mechanism, and achieve weight reduction, complexity reduction, and Moment of inertia, material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

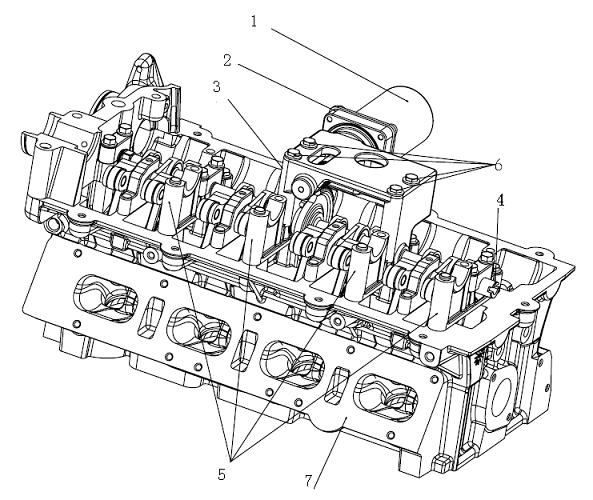

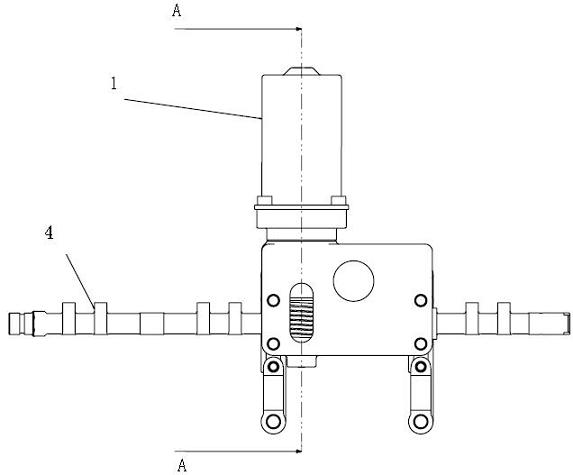

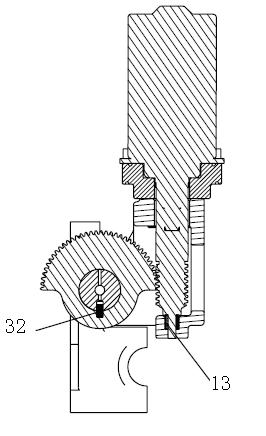

[0032] Combine below Figure 1 to Figure 8 , the present invention is further described:

[0033] Such as figure 1 and Figure 6 As shown, an eccentric shaft control system of a fully variable valve lift mechanism, the engine cylinder head 7 is equipped with a bearing seat 5, the bearing seat 5 is equipped with an eccentric shaft 4, the eccentric shaft 4 is provided with an eccentric wheel 43, and also includes a Bearing cap assembly 3, the bearing cap assembly 3 is used to limit the eccentric shaft 4 on the bearing seat 5, the bolt 6 is used for fastening; the worm 12 is installed on the rotor of the motor 1, and the worm wheel 14 is fixedly connected to the journal of the eccentric shaft 44, the motor 1 drives the worm 12 and the worm gear 14 to mesh with each other. Under the action of an angle limit device, the eccentric shaft 4 only needs to rotate from 0 to 180 degrees to realize the adjustment of the valve lift from zero to the maximum value. between adjustments.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com