Assembling method of electromagnetic valve assembly

An assembly method and solenoid valve technology, which are applied in the valve operation/release device, valve device, valve details, etc., can solve the problems of easy over-pressing, the valve seat is not pressed in place, the air gap G becomes larger, etc. The effect of manufacturing yield, increasing reliability, and simplifying assembly structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

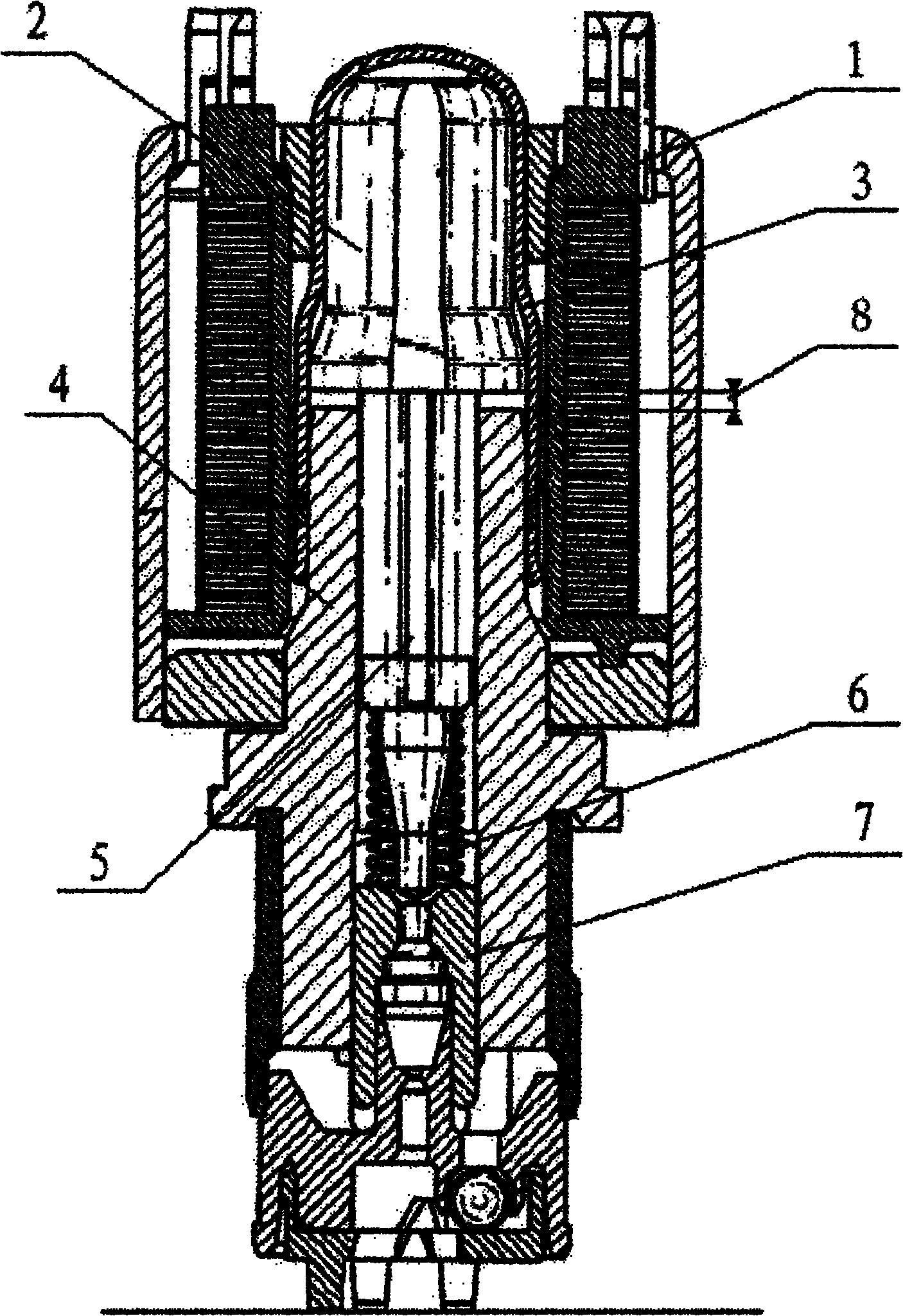

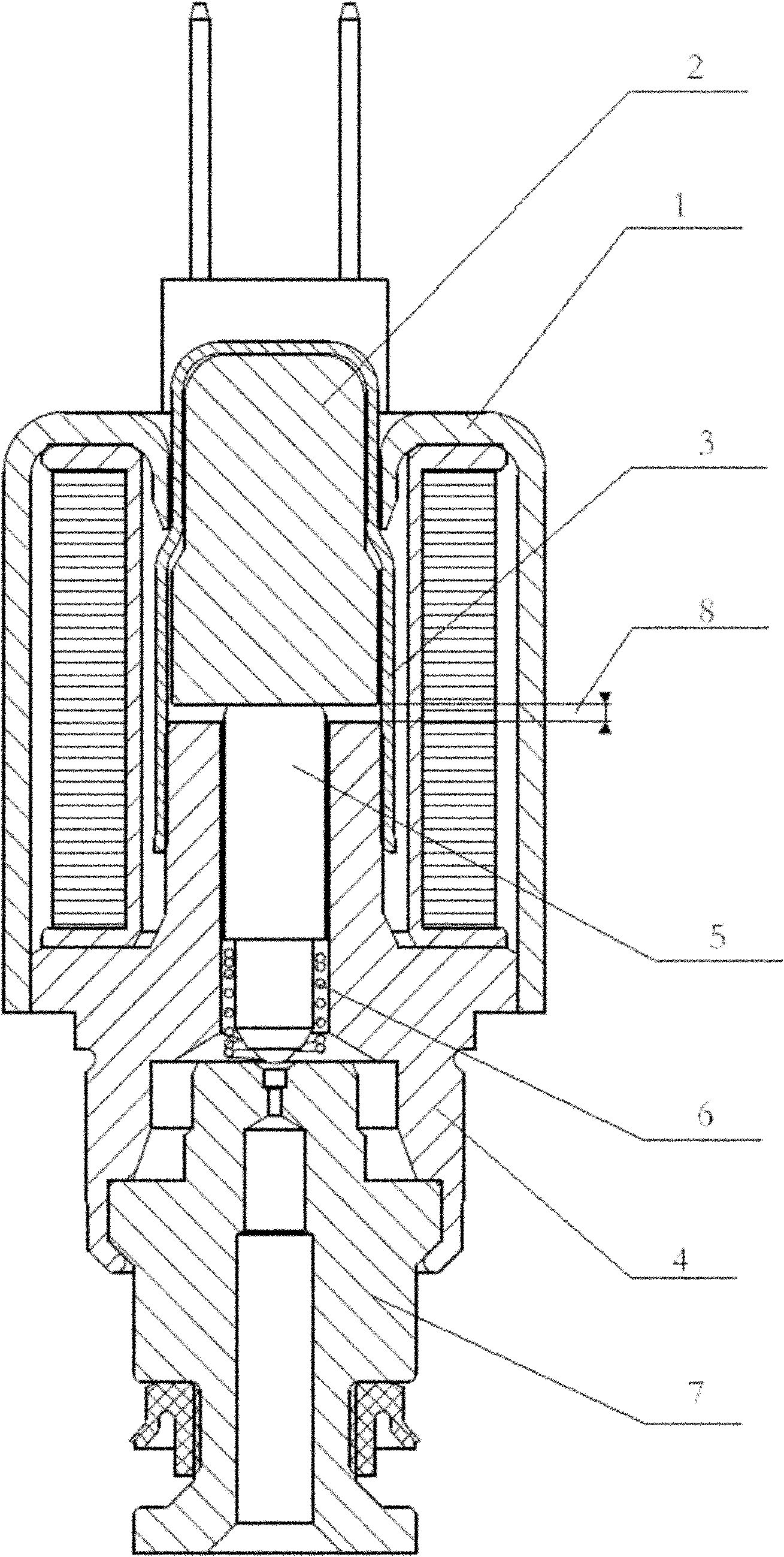

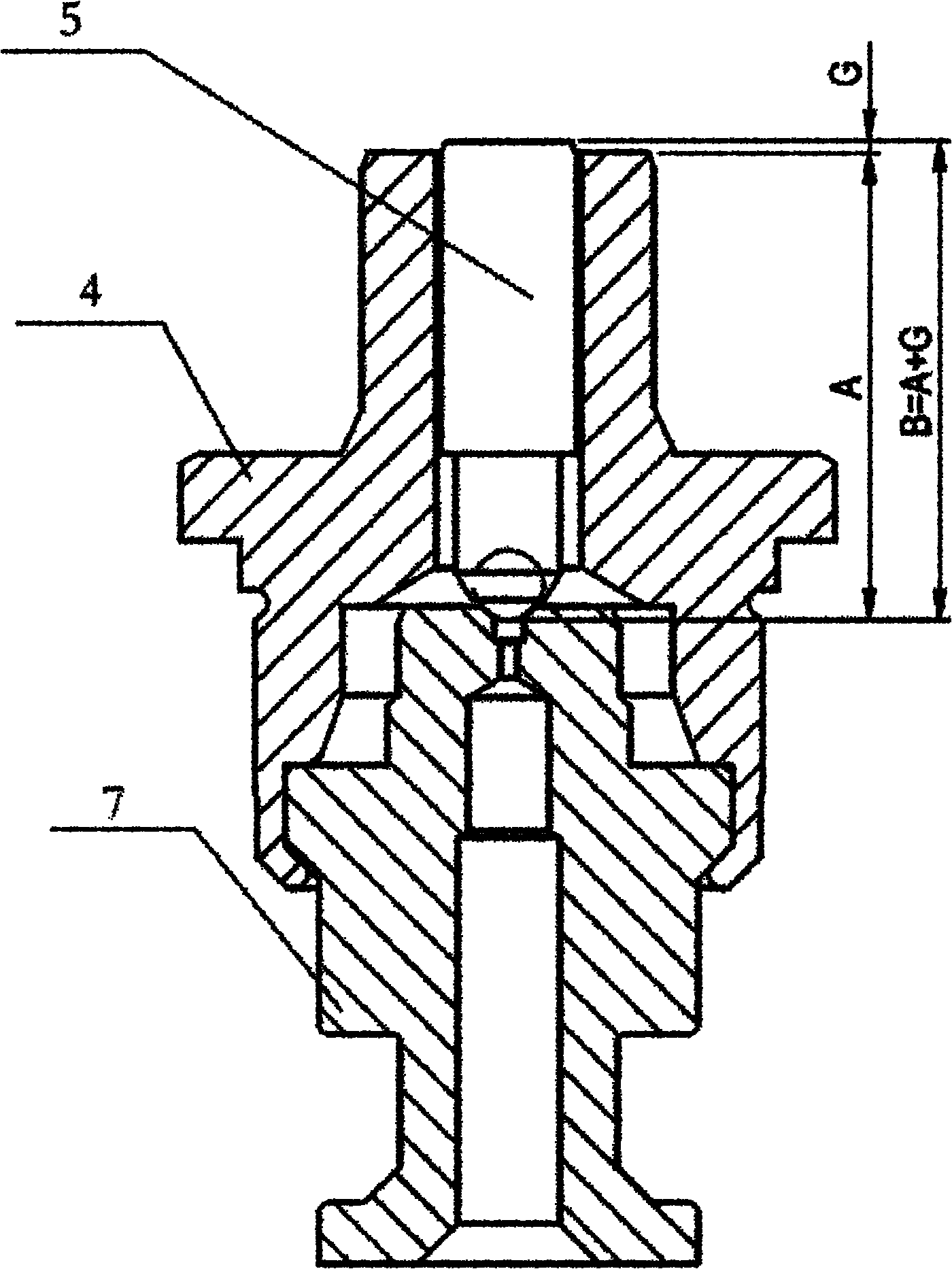

[0021] Such as figure 2 , 3 , 4 shows the schematic diagram of the solenoid valve structure. It can be seen that the valve seat 7 is inserted into the valve casing 4, and the valve casing 4 is in the shape of a hole step at the end where the valve seat 7 is inserted. After the valve seat 7 is inserted, it is stuck in this hole step and riveted with the valve casing 4. . The size of the valve stem 5 of the present invention is determined after the valve seat 7 and the valve housing 4 are installed. As long as the required size of the valve stem 5 is accurate, the accuracy of the air gap 8 can be guaranteed, which reduces unstable factors and improves the reliability of the product. sex.

[0022] The determination of above-mentioned valve stem 5 and its installation scheme are as follows:

[0023] Step a: Determine the possible required length range of the valve stem 5 according to the processing error and the mutual assembly error related to the valve casing 4 and the valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com