Silicon controlled rectifier stator voltage-regulation and speed-regulation parallel operation electric control system

An electric control system, technology of thyristor stator, applied in the direction of speed adjustment of multiple motors, to achieve the effect of overcoming capacity shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

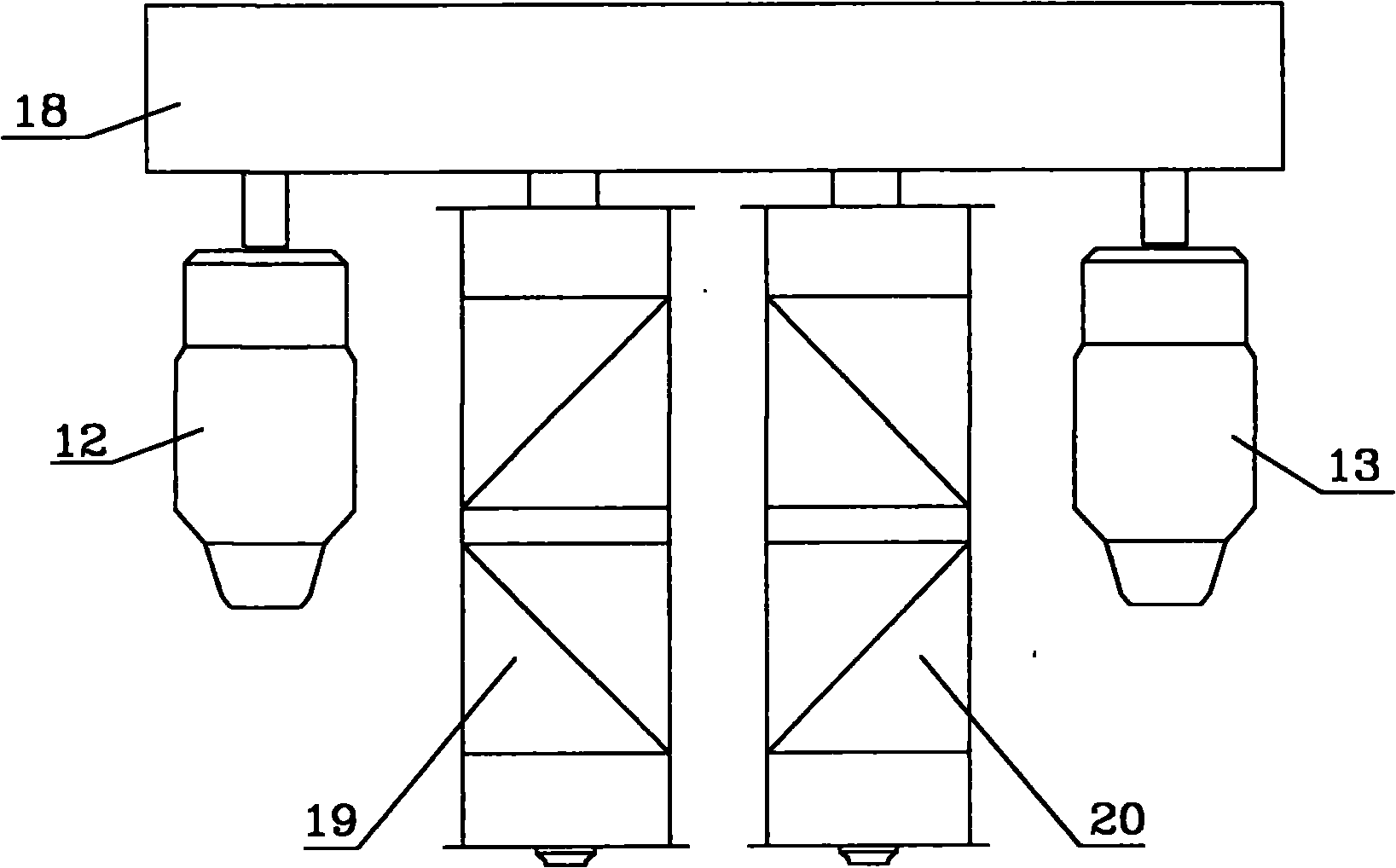

[0020] figure 1 As shown, the mechanical transmission system of the main hoisting mechanism of a large crane uses two motors 12 and 13 (No. 1 and No. 2 motors) to drive the same reducer 18 to work. Hard connection at the place finally drives two sets of wire rope reels 19,20 to wind the wire rope.

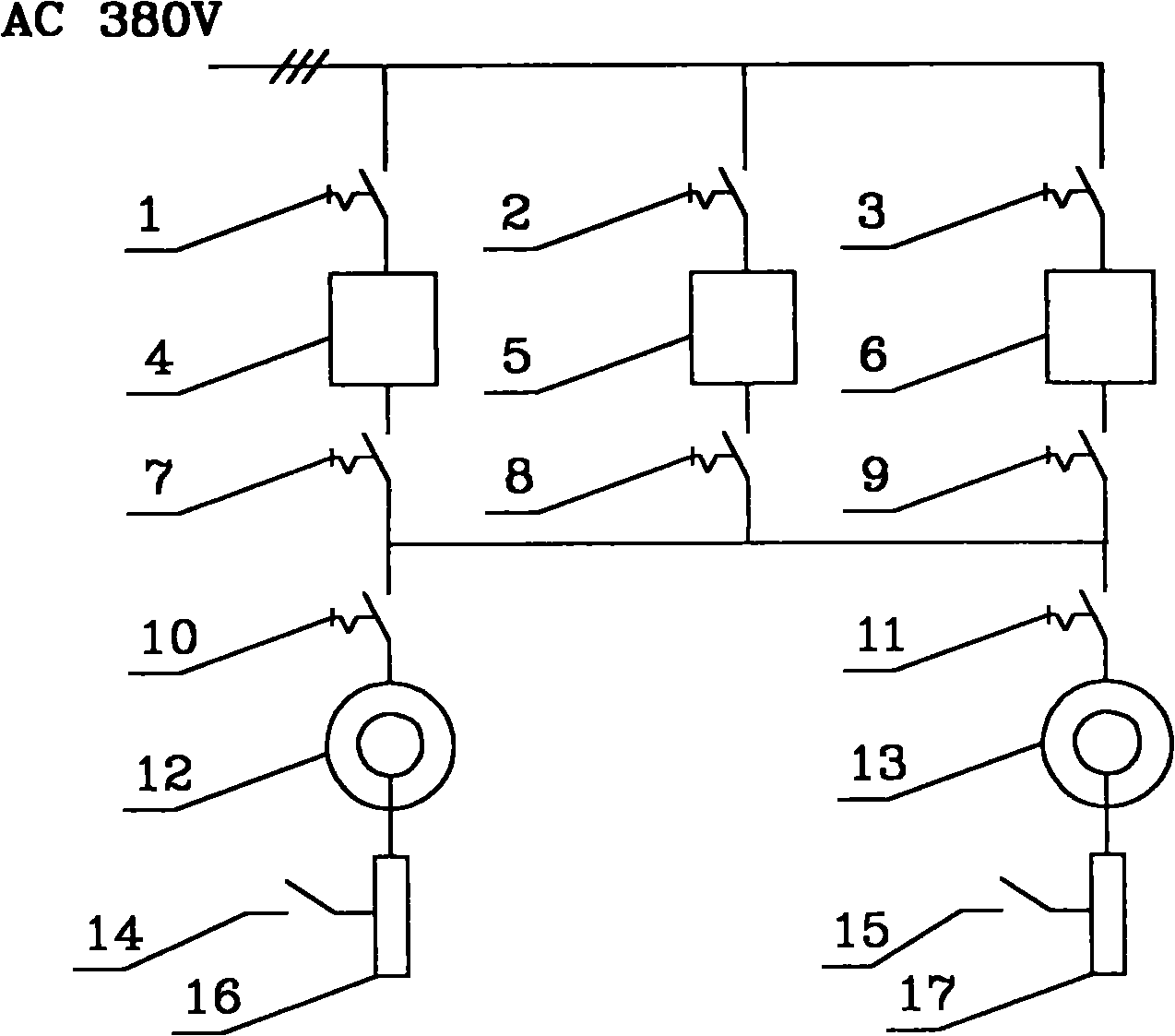

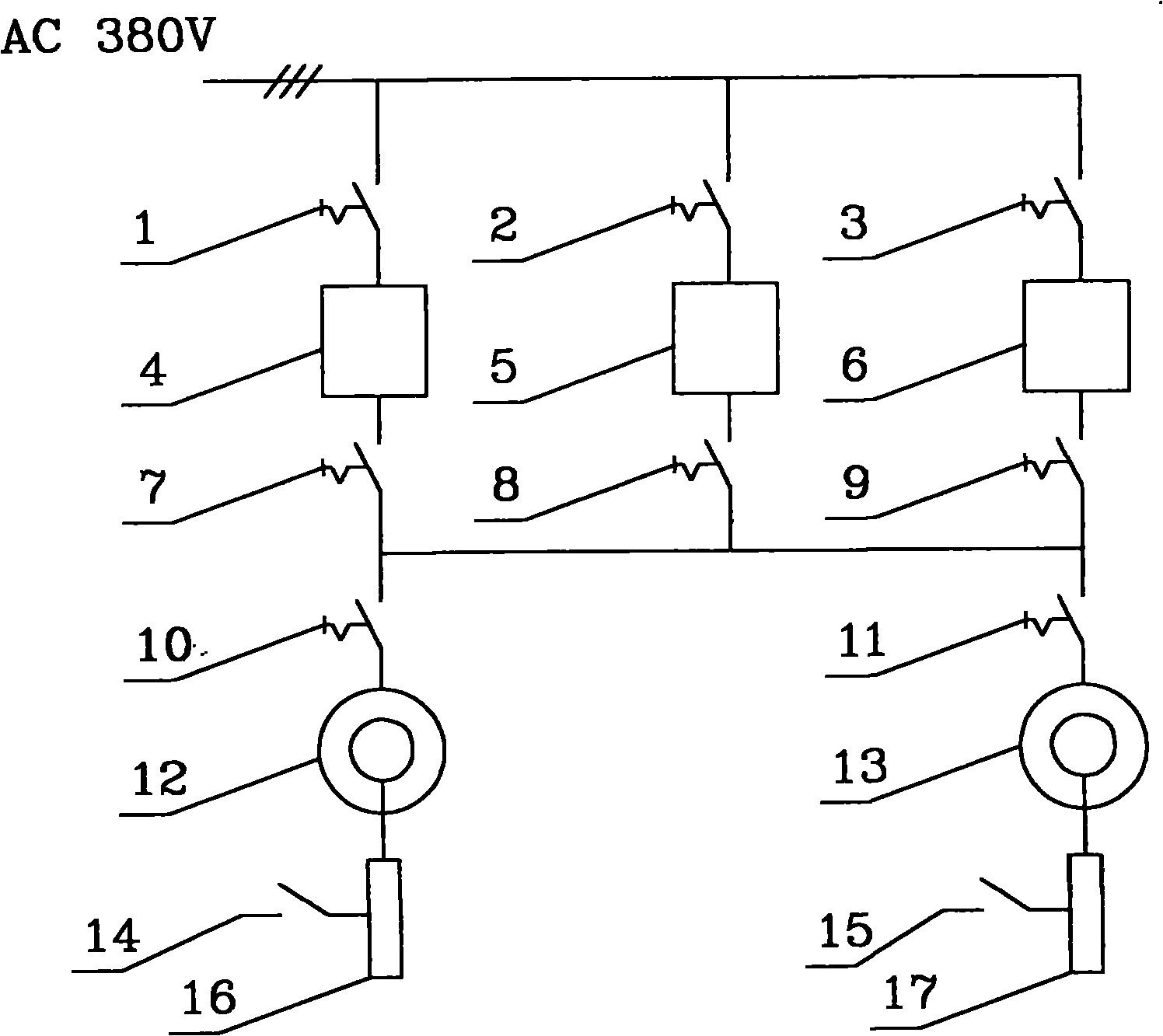

[0021] figure 2 As shown, the electrical control system of the three-to-two mode of the thyristor stator voltage regulation and speed regulation of the main hoisting mechanism of a large crane. The electrical control system for voltage regulation and speed regulation includes three sets of power supply devices and two sets of drive devices. After the output voltages regulated by the three sets of power supply devices are connected in parallel, the two sets of drive devices are connected to supply power. in:

[0022] The three sets of power sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com