A liquid distillation condensing device

A distillation condensing device and liquid technology, applied in distillation separation, vapor condensation, reflux condensation, etc., can solve the problems of inconvenient removal of distillation bottles, low space utilization, easy bumping and scratching, etc., to ensure circulating cooling. effect, increase efficiency and effectiveness, avoid the effect of retort contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

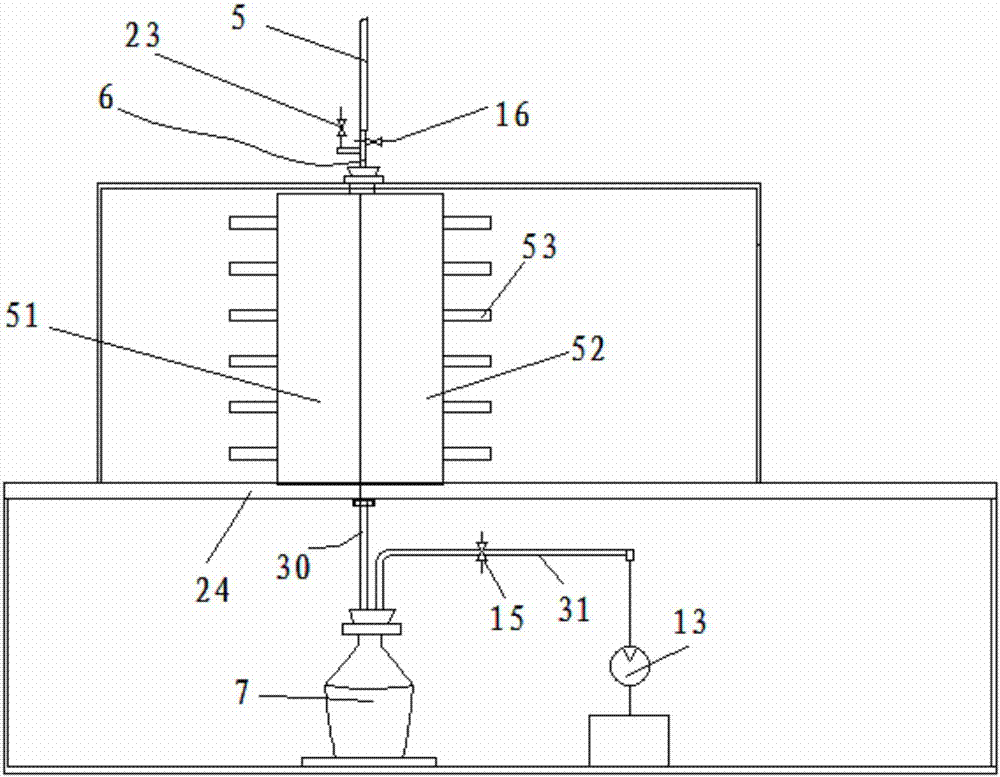

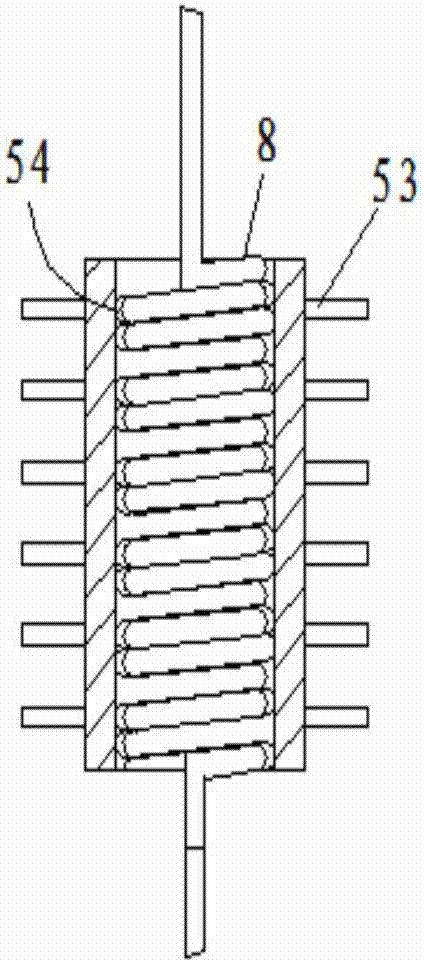

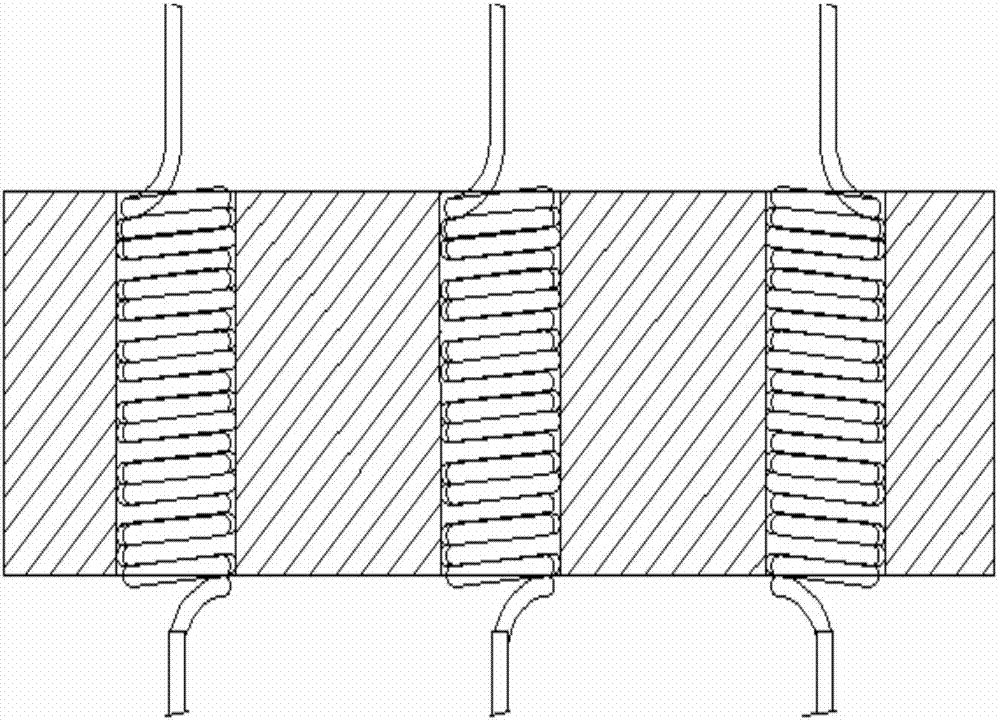

[0019] combine Figure 1 to Figure 3 , a liquid distillation condensing device, comprising a condensing sleeve, the condensing sleeve is supported on the housing 24 at the bottom of the retort, the upper end of the spiral condensing tube 8 is connected to the lower end of the conduit through a valve 6, and the upper end of the conduit 5 is connected to the retort The gas outlet is connected, the lower end of the spiral condensing tube is connected with the reflux bottle 7, the reflux bottle 7 is arranged at the lower part of the housing, the mouth of the reflux bottle 7 is provided with an air outlet pipe, 31, and the outlet pipe is connected with the negative pressure pump 13, An on-off valve 3 15 is provided on the outlet pipe, and the condensation sleeve is provided with an inner hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com