Liquid Distillation Condenser

A technology of distillation and condensation device and liquid, which is applied in distillation separation, heating water/sewage treatment, chemical instruments and methods, etc., can solve the problems of high use cost, heavy quality, low space utilization, etc., to improve efficiency and benefit, The effect of reducing production costs and accelerating evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

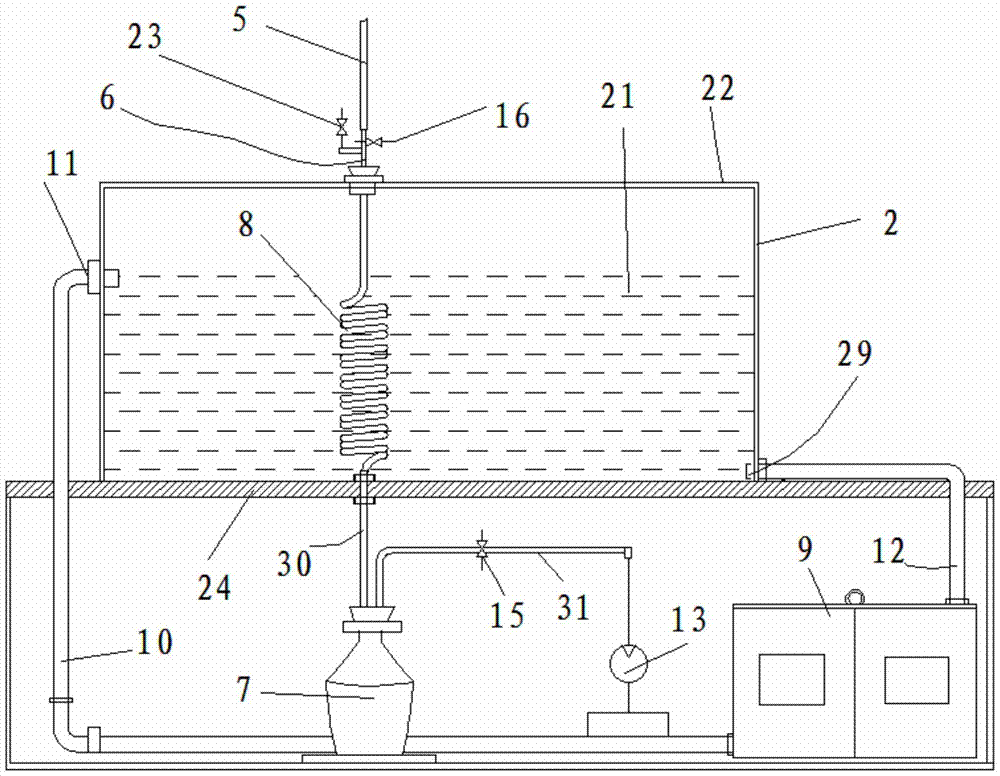

[0021] Example 1, such as figure 1 As shown, a liquid distillation condensing device includes a spiral condensation tube 8 and a condensation medium 21. The condensation medium 21 is arranged in a closed box 22, and the condensation tube 8 is arranged in the box 22 and connected with the box. The upper end of the condensation pipe 8 is connected with the two ends of the three-way valve 6 through the lower end of the conduit 5, the upper end of the conduit 5 is connected with the gas outlet of the retort, and the position of the box in the height direction is lower than the bottom of the retort, wherein The upper end of the spiral condensing pipe 8 is connected to the lower outlet of the three-way valve 6, the lower end of the conduit 5 is connected to the upper outlet of the three-way valve 6, the inlet of the three-way valve 6 is connected to the cleaning water pipeline, and a switch valve is arranged on the cleaning water pipeline. 23. An on-off valve 2 16 is provided on the...

Embodiment 2

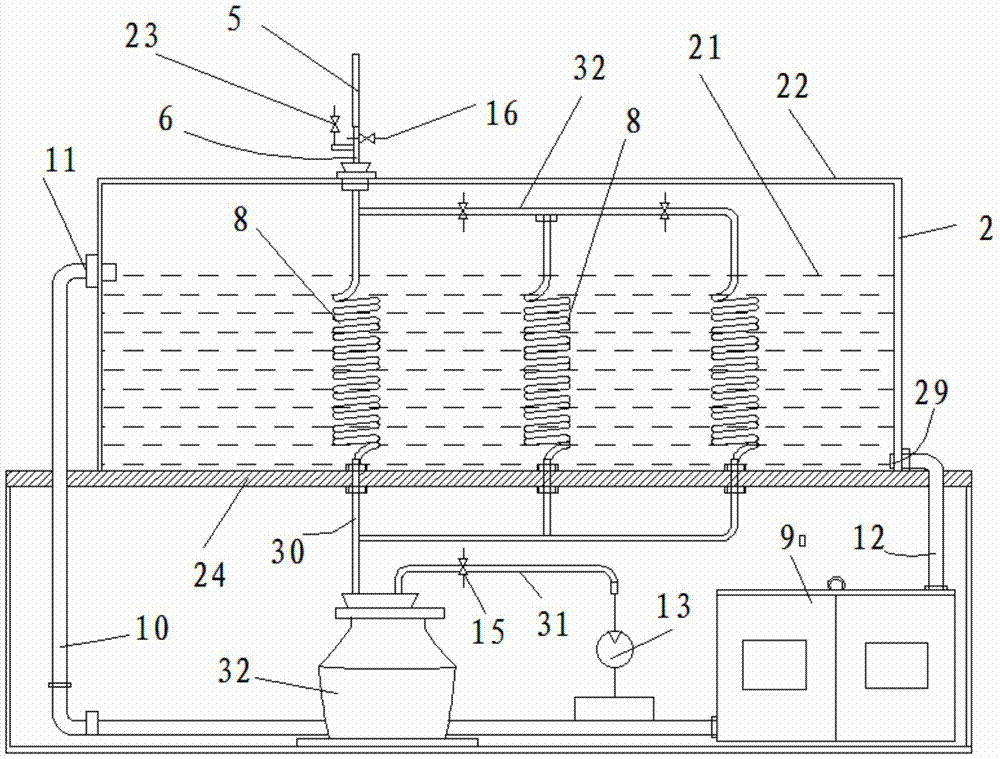

[0026] Such as figure 2 As shown, on the basis of Embodiment 1, a plurality of parallel condensing pipes 8 are provided in the casing 22 through pipeline connections, and a plurality of parallel condensing pipes 8 are connected with a large reflux bottle 32 at the bottom simultaneously, or respectively Connect with respective reflux bottle 7. When utilizing the technical scheme of this embodiment, the matching distilling bottle, heater, conduit 5, etc. adopt a structure larger than the size parameter of the single condensation tube 8 structure, and when the overall structure size increases less, It can greatly improve the working efficiency of distillation, especially suitable for occasions where a large amount of distilled water needs to be supplied, and where a single operator needs to operate multiple devices at the same time, reducing the labor intensity of a single operator and reducing labor costs. At the same time, the structure is compact, In the relatively tight use...

Embodiment 3

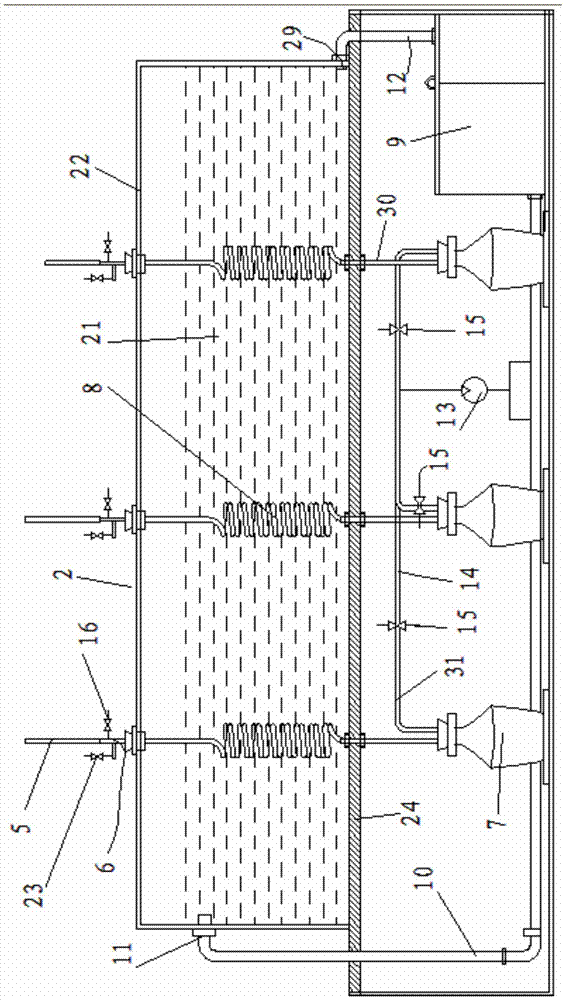

[0028] Such as image 3As shown, on the basis of Embodiment 1, the technical solution of this embodiment adopts multiple parallel conduits 5, the condensation pipe 8, the guide pipe 30 and the conduits 5 are arranged correspondingly, and each conduit 5 is connected with the corresponding parallel collectors respectively. The retort, the heater are connected, and the reflux bottle 7 corresponds to the guide tube 30, and the retort, the heater, the conduit 5, etc. in this embodiment can adopt a structure smaller than the size parameter of the single condensation pipe 8 structure, Due to the small size of each set of distillation structures, enough individual distillation bottles, heaters and other distillation structures can be arranged on a support platform 20 at the same time, and even the same distillation structure can be arranged around a large support platform 20 , this kind of technical scheme is suitable for public places such as schools, for students to conduct distilla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com