Inverted tooth chain sprocket drive system with reduced meshing impact

A technology of sprocket drive and reverse tooth chain, which is applied in the direction of belt/chain/gear, transmission chain, transmission device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

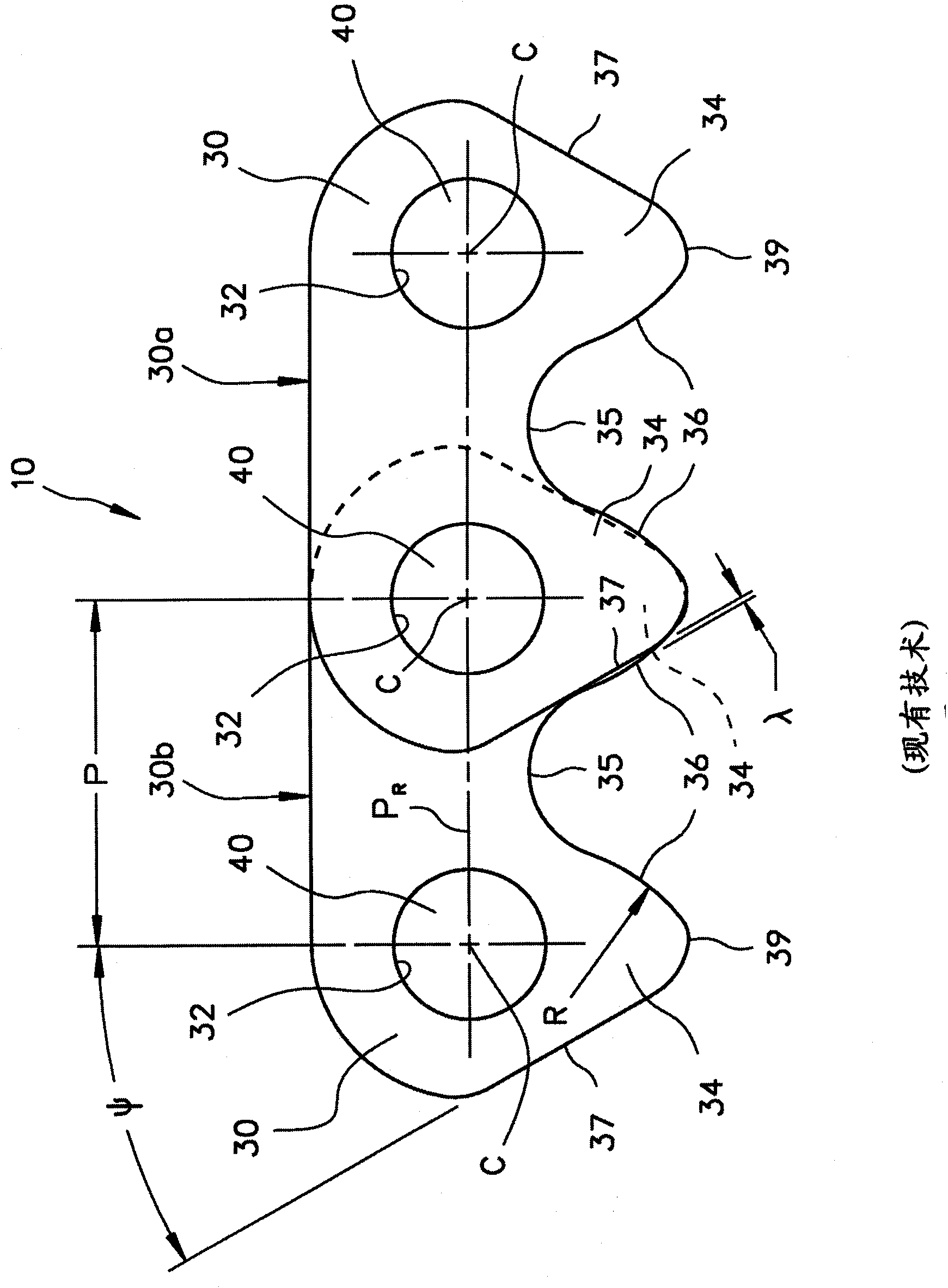

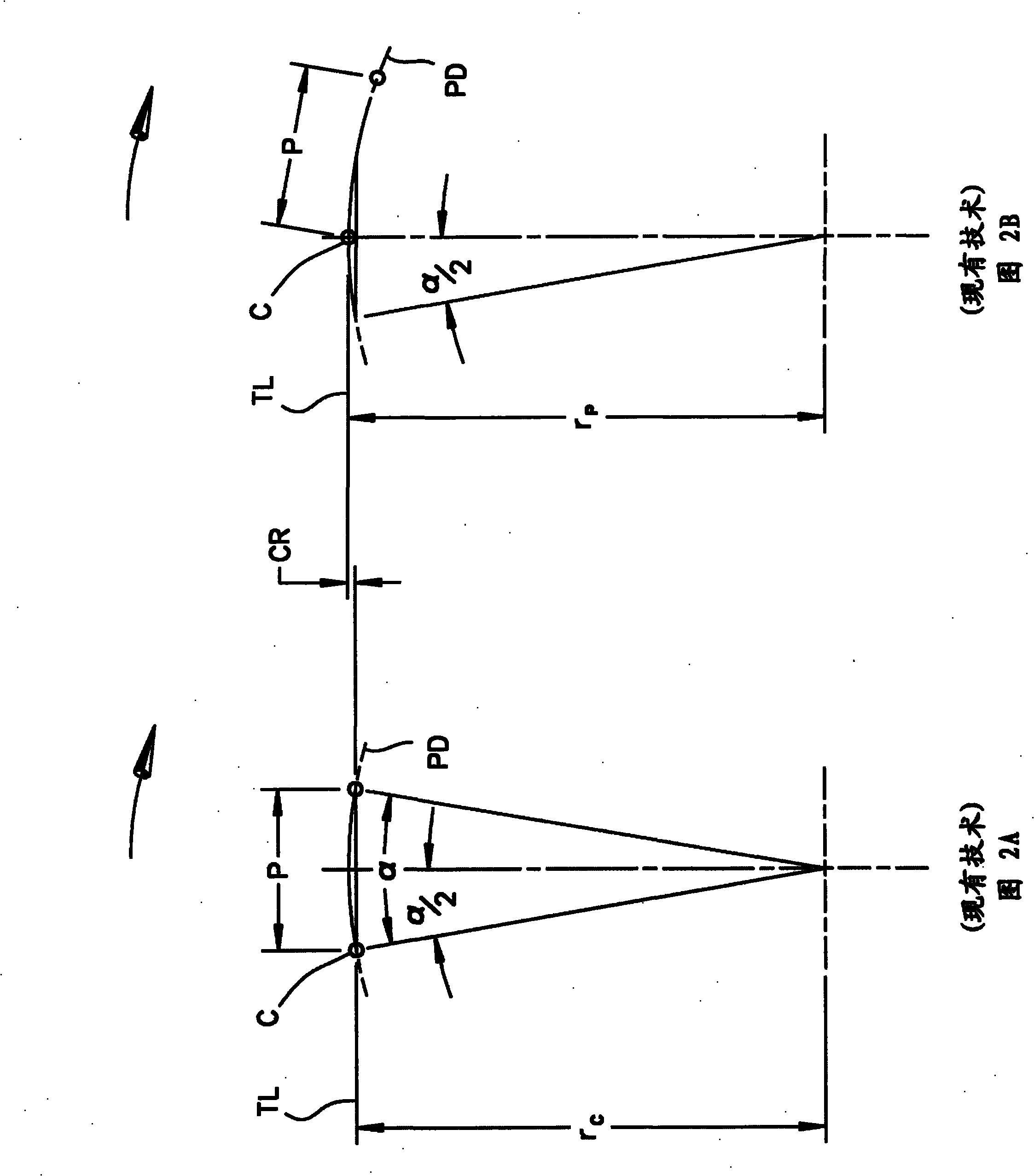

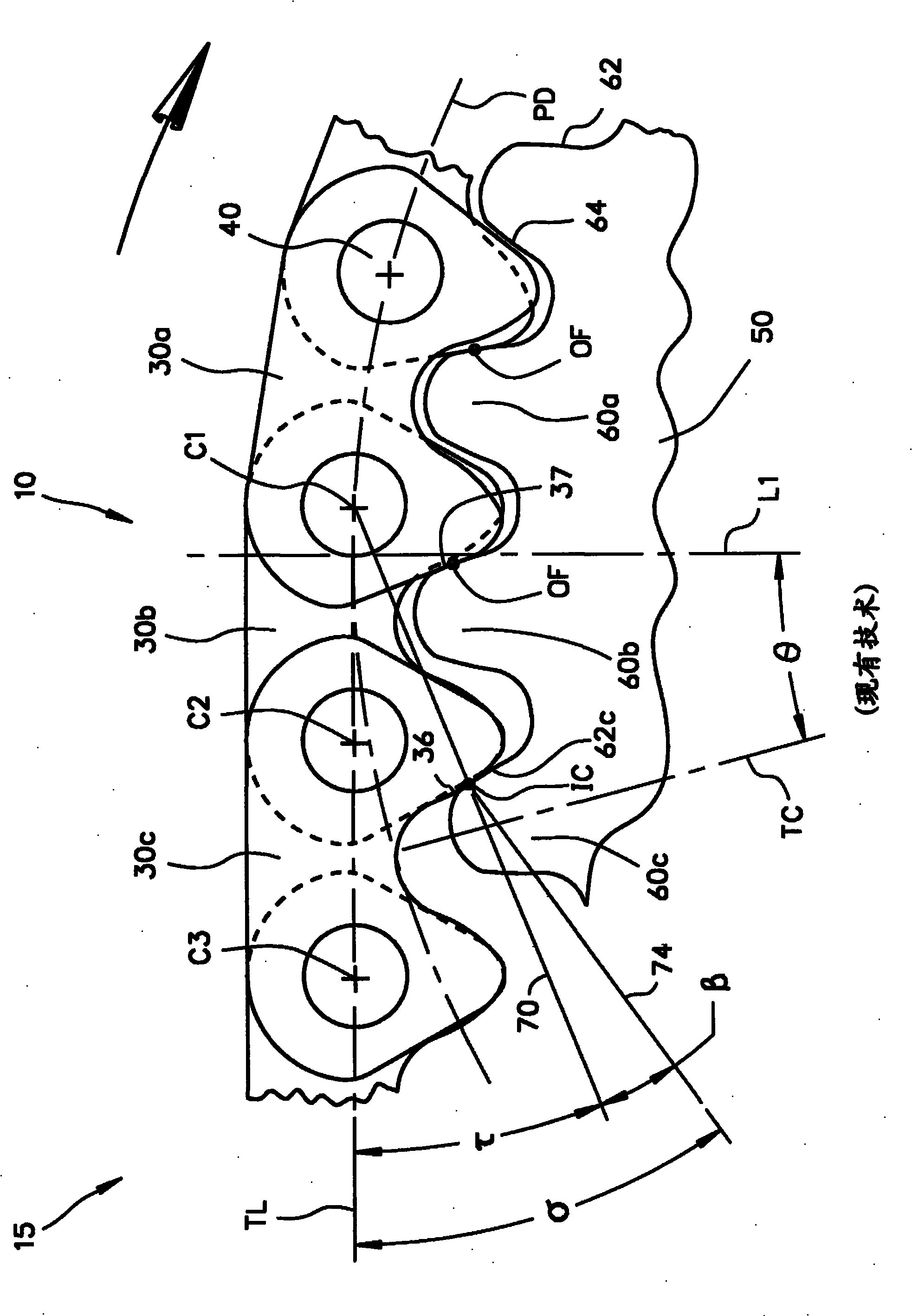

[0078] Figure 5 An enlarged schematic view of the first and second rows of inboard side engagement of an inverted tooth chain 110 according to the present modification (chain guides not shown), showing the preferred inboard side protrusion Lamda (λ) and the outboard side contour. Figure 5A for Figure 5 Enlarged view of middle detail area 5A showing the inboard side protrusion λ relative to the outboard side ramp 138 near the link tooth tip 139 T . Figure 5B To include according to the present invention, Figure 5 An isometric view of a section of chain of link plates is shown, thereby forming the inverted tooth chain 110 .

[0079] Chain 110 includes rows or rows 130a, 130b, 130c, etc., of interleaved inner links or link plates 130, each of which includes a pair of teeth 134 having an outer side 137 and an inner side 136, and, between teeth 134, A crotch 135 is formed between the medial sides 136 . Teeth 134 have respective tips or tips 139 . Each link piece 130 has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com