Retroreflective articles having microcubes, and tools and methods for forming microcubes

a technology of retroreflective elements and retroreflective objects, which is applied in the direction of instruments, other domestic objects, transportation and packaging, etc., can solve the problems of limiting the percent active aperture to less than 100%, reducing the size of the microcube, and reducing the application of known optical principles. , to achieve the effect of increasing the active apertur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Retroreflectors For Increased Entrance Angularity

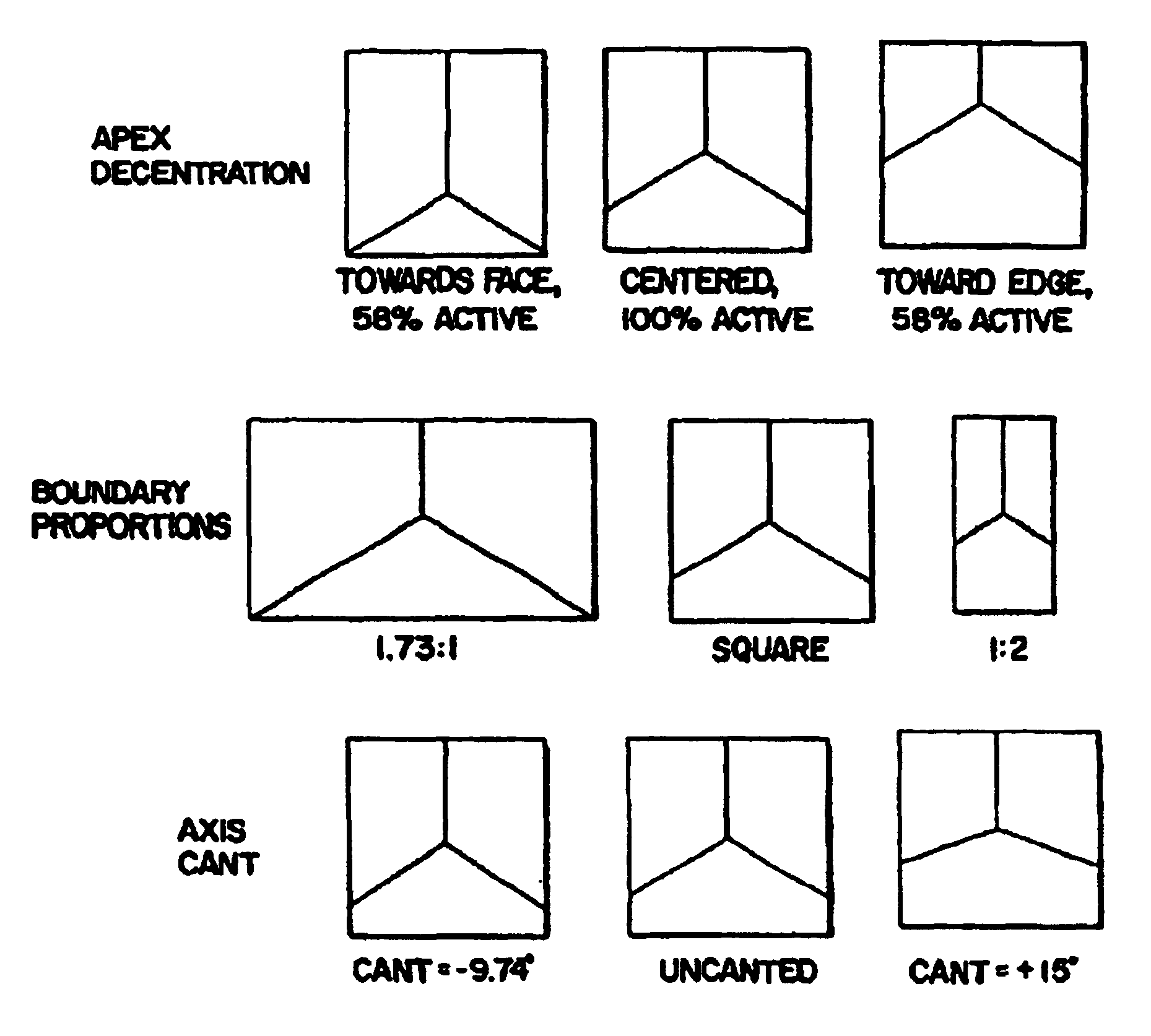

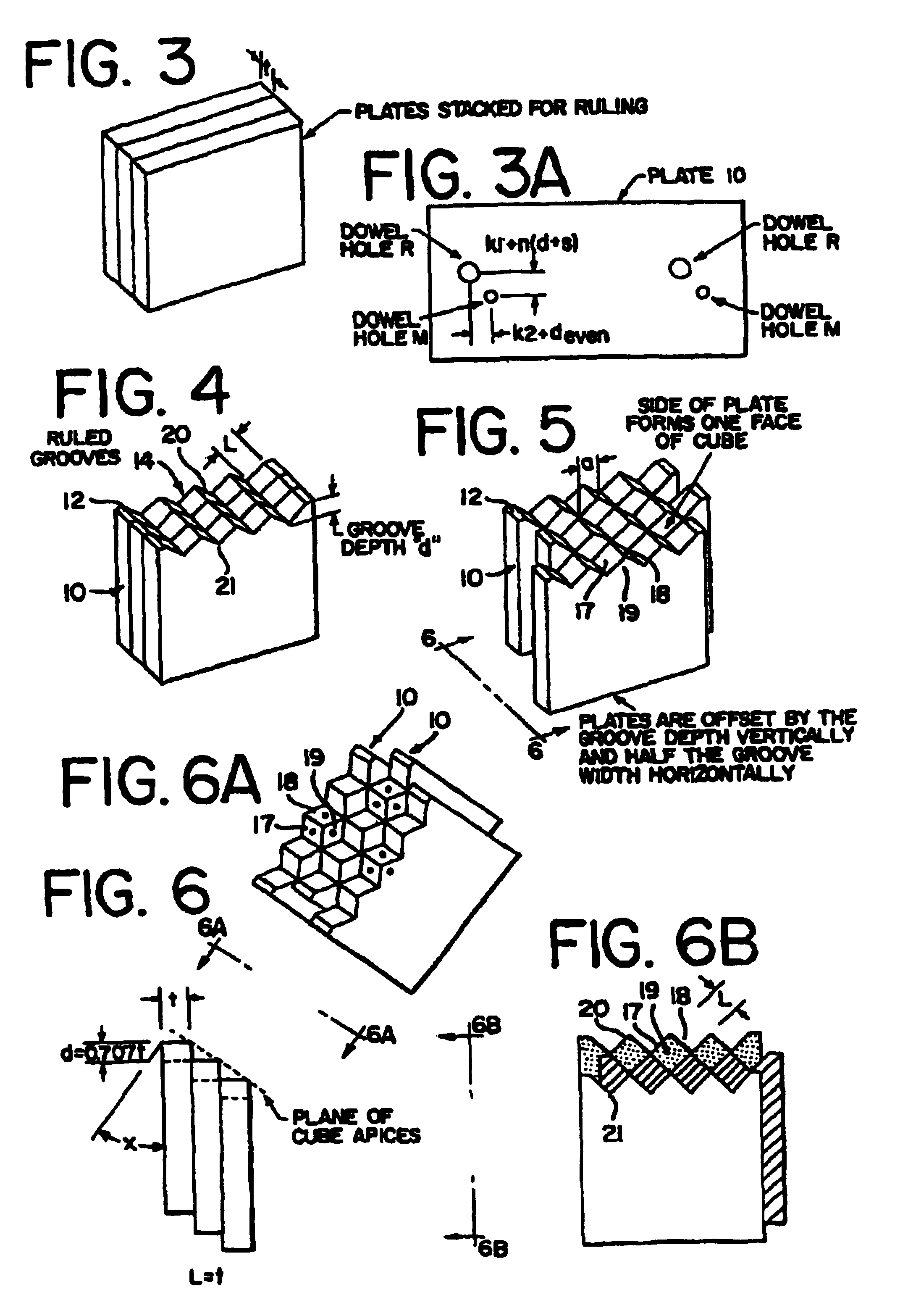

[0225]To increase the entrance angularity of the cubes as described in patents U.S. Pat. Nos. 3,541,606, 3,873,184 and U.S. Pat. No. 3,923,378 issued to the same assignee and incorporated herein by reference, the s / t=0, d / t=0.707 solution shown in FIG. 6 might be superseded by an s / t=0.45; d / t=0.55 solution as shown in FIG. 13, for which the cube axis tilt is −9.74° to the front surface of the array and the percent active aperture is 72.5% at 0° incidence angle and 100% at 19.6° incidence angle. (Throughout this example, the entrance plane is assumed to be aligned with the symmetry plane of the cube corners, and the refractive index is assumed to be 1.59.) However, if the hexagon arrays are paired for each cube favorably oriented for 19.6° incidence angle, there is also its mirror image having only 45% effective aperture for that same incident light; the paired array therefore averages 72.5% for light incident at an angle of 19.6°, wh...

example 2

Retroreflectors For Large Incidence Angles, Such As For Pavement Markers

[0231]Example 2 is quite different. The method of Example 2 is intended to maximize the retroreflectance through a relatively smaller range of entrance angles about an axis (the principal incident ray) which is not normal to the face of the retroreflector. For example, a raised retroreflective lane marker mounted on a road may have its front surface tilted back 60° from a plane perpendicular to the plane of the pavement. A light ray from the headlight of an approaching vehicle, being substantially parallel to the pavement, becomes incident on the face of the retroreflector at an angle to the normal of 60° and is refracted (in acrylic) to an angle to the normal of 35.5°. For purposes of discussion, the ray parallel to the pavement surface and to the centerline of the road will be called the principal incident ray of optical axis and the ray within the marker after reflection at the front surface will be called th...

example 3

Retroreflectors With Increased Divergence

[0239]The divergence of the retroreflected beam (i.e., the observation angularity) can be varied in one plane or in multiple planes by changing the dihedral angles between either two or three faces as taught in U.S. Pat. No. 3,833,285 also to the same assignee and incorporated herein by reference and / or by changing the size of the cube, which affects diffraction.

[0240]The dihedral angle can be changed by making the groove angle greater or less than 90° and / or by tilting the stack of plates 10 slightly off the perpendicular to the cutting plane, as illustrated by angle “b” in FIG. 11, before the grooves are cut. The groove angle can be varied by changing the angle “C” of the diamond tool (FIG. 7A) or by adjusting the angle “e” of the diamond tool (FIG. 8B) with respect to the perpendicular to the surface being ruled, in accordance with Equation A, previously stated.

[0241]The tilt angle “e” of the cutting tool can be held constant for all groov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com