Ceramic heater

A ceramic heater and ceramic technology, applied in the direction of ohmic resistance heating, heating element materials, electric heating devices, etc., can solve the problems of ceramic substrate cracking and unbearable, so as to prevent heater cracking, improve efficiency, and shorten heating time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

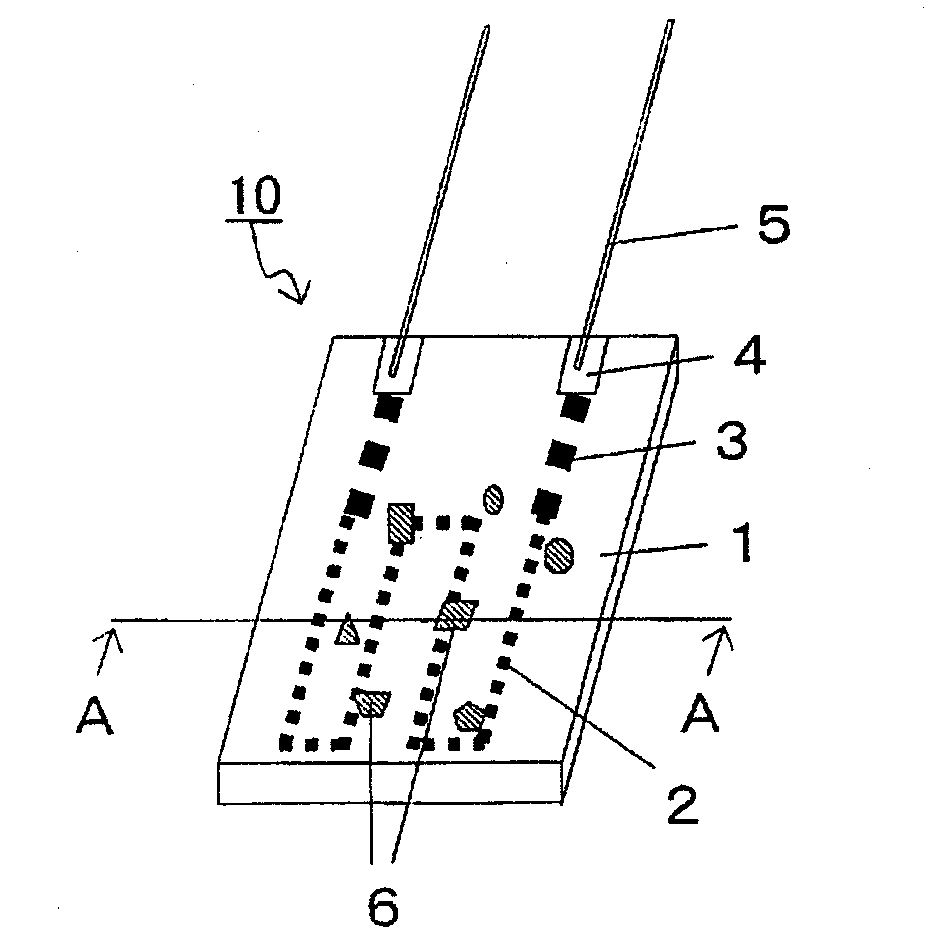

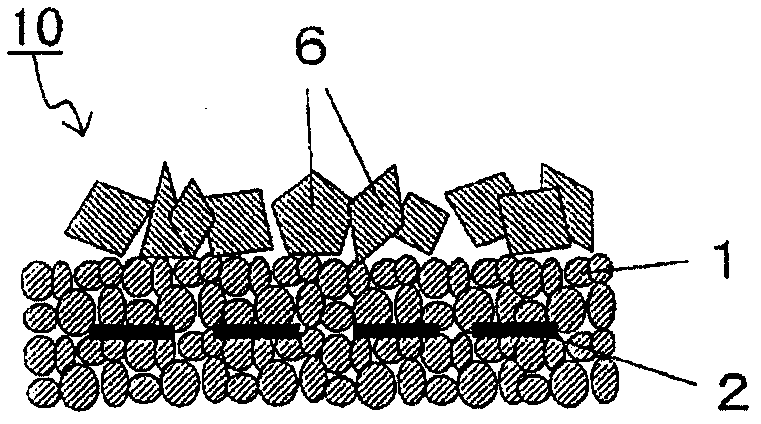

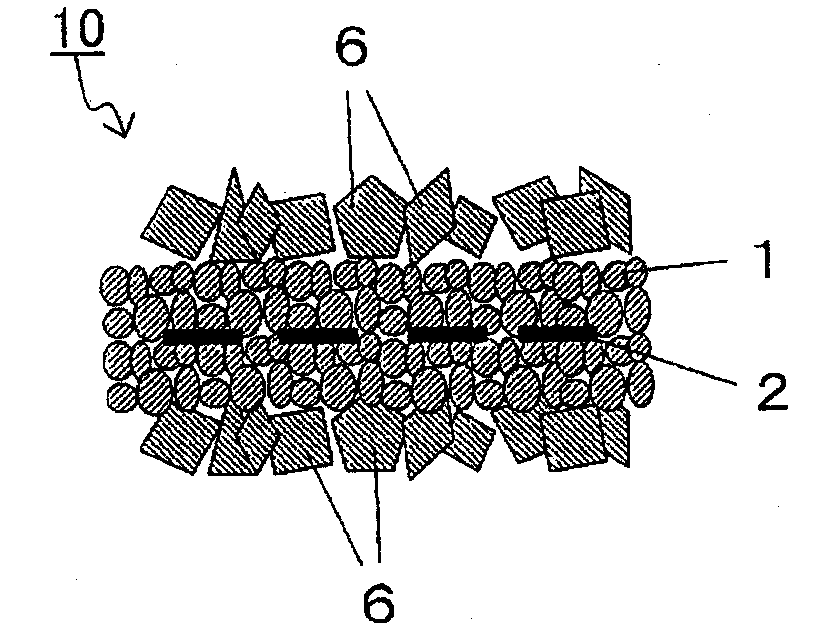

[0060] made as follows Figure 1 ~ Figure 3 A ceramic heater 10 of the present invention is shown.

[0061] First, make the following Al 2 o 3 as the main component, SiO 2 , CaO, MgO, ZrO 2A ceramic green sheet prepared so that the total amount is within 10% by mass. Then, on the surface of the ceramic green sheet, the heating element 2 , the lead portion 3 , and a conductive paste mainly composed of W serving as the electrode pad 4 were printed in a pattern by screen printing. Ceramic green sheets printed with these patterns and non-printed ceramic green sheets of the same material and shape were coated and laminated with a lamination liquid in which ceramics of the same composition were dispersed to obtain a plate-like molded body.

[0062] Next, a plurality of particles 6 are printed and applied to the main surface of the stacked plate-like molded body by the screen printing method. In addition, for the sample in which the particles 6 were fixed to both main surfaces,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com