Follow-up supporting tool bit device used for processing deep hole

A follow-up, cutter head technology, used in metal processing equipment, tools for lathes, tool holders, etc., can solve the problems of too long boring bars, expensive boring machines, and insufficient machining accuracy, and prevent scratches. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

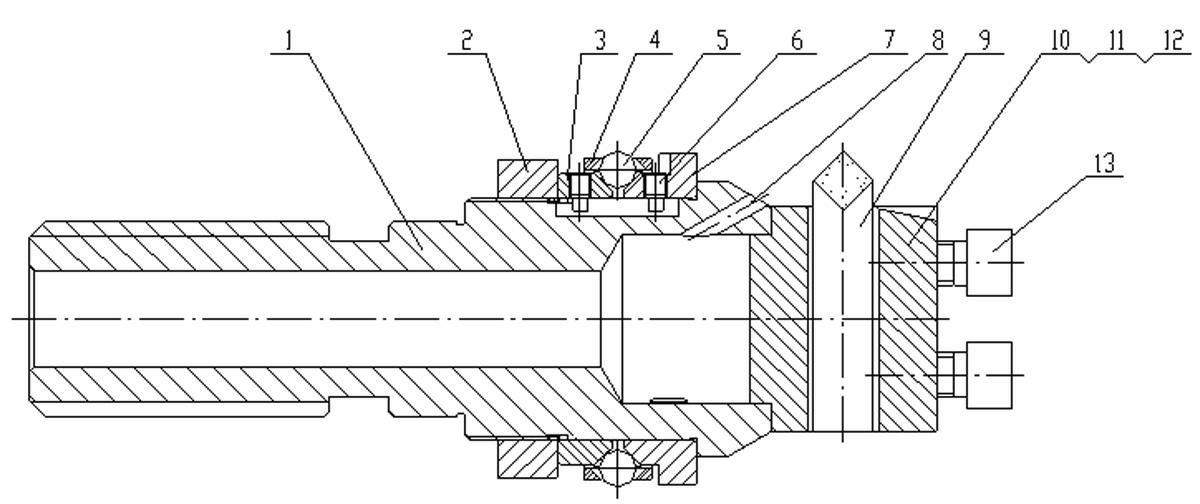

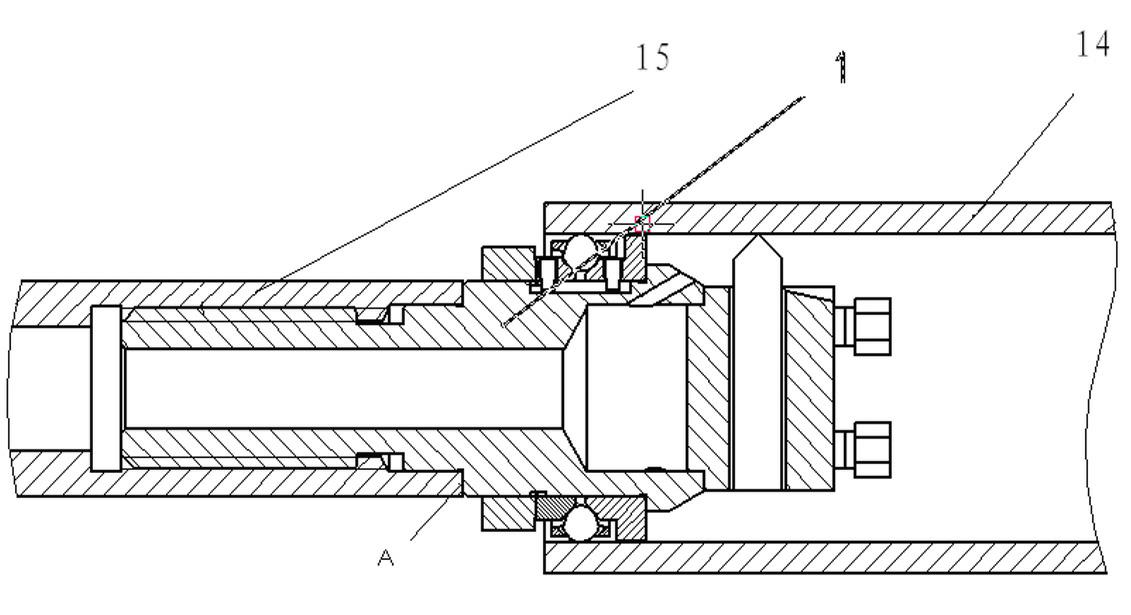

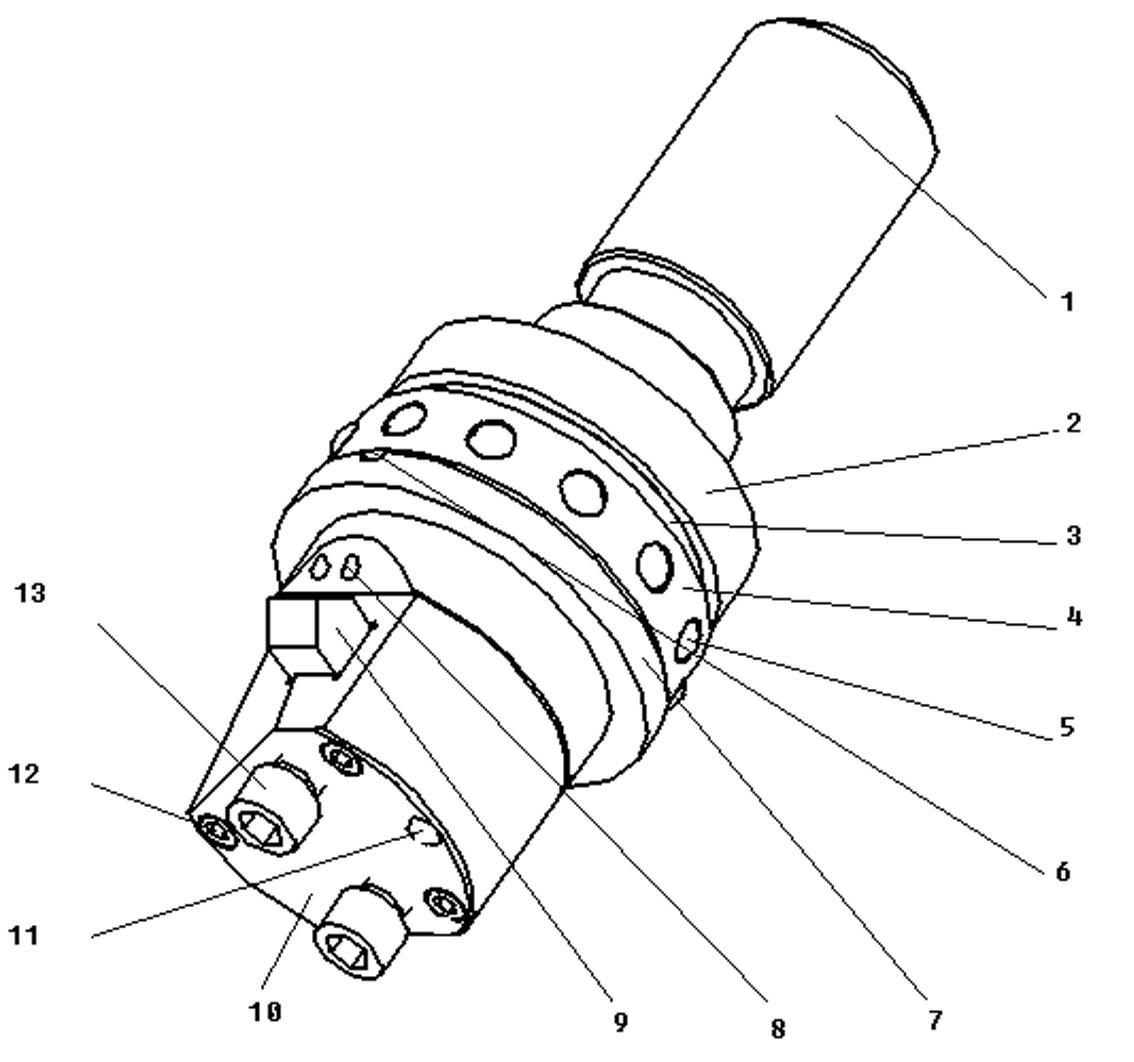

[0011] The present invention will be further described below in conjunction with accompanying drawing.

[0012] Referring to the attached picture:

[0013] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0014] A cutter body 1 with a hollow structure is fixed with an internally threaded cylindrical pin 11 and a hexagon socket head screw 12 in front of the tool holder 10; a T-shaped thread connection is used between the cutter body 1 of the hollow structure and the hollow boring bar 15, and the outer circle The end face turning tool 9 is installed on the tool holder 10 with a hexagon socket head cap screw 13 .

[0015] V-shaped blocks 3 and 7 are respectively fixed on the front and rear ends of the outer cylindrical surface of the cutter body 1 of the hollow structure by cylindrical end set screws 6, and the V-shaped grooves formed between the two V-shaped blocks are evenly distributed. 12 adjusting ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com