Preparation method of organic-inorganic composite

An inorganic composite material and inorganic technology, applied in the direction of inorganic pigment treatment, dyed organosilicon compound treatment, dyed polymer organic compound treatment, etc., can solve the problem of increasing the cost of organic-inorganic composite materials, the inability to form inorganic phases in situ, and the lack of There are problems such as reactivity, so as to achieve the effects of reducing preparation costs, reducing energy consumption, and slowing stress release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

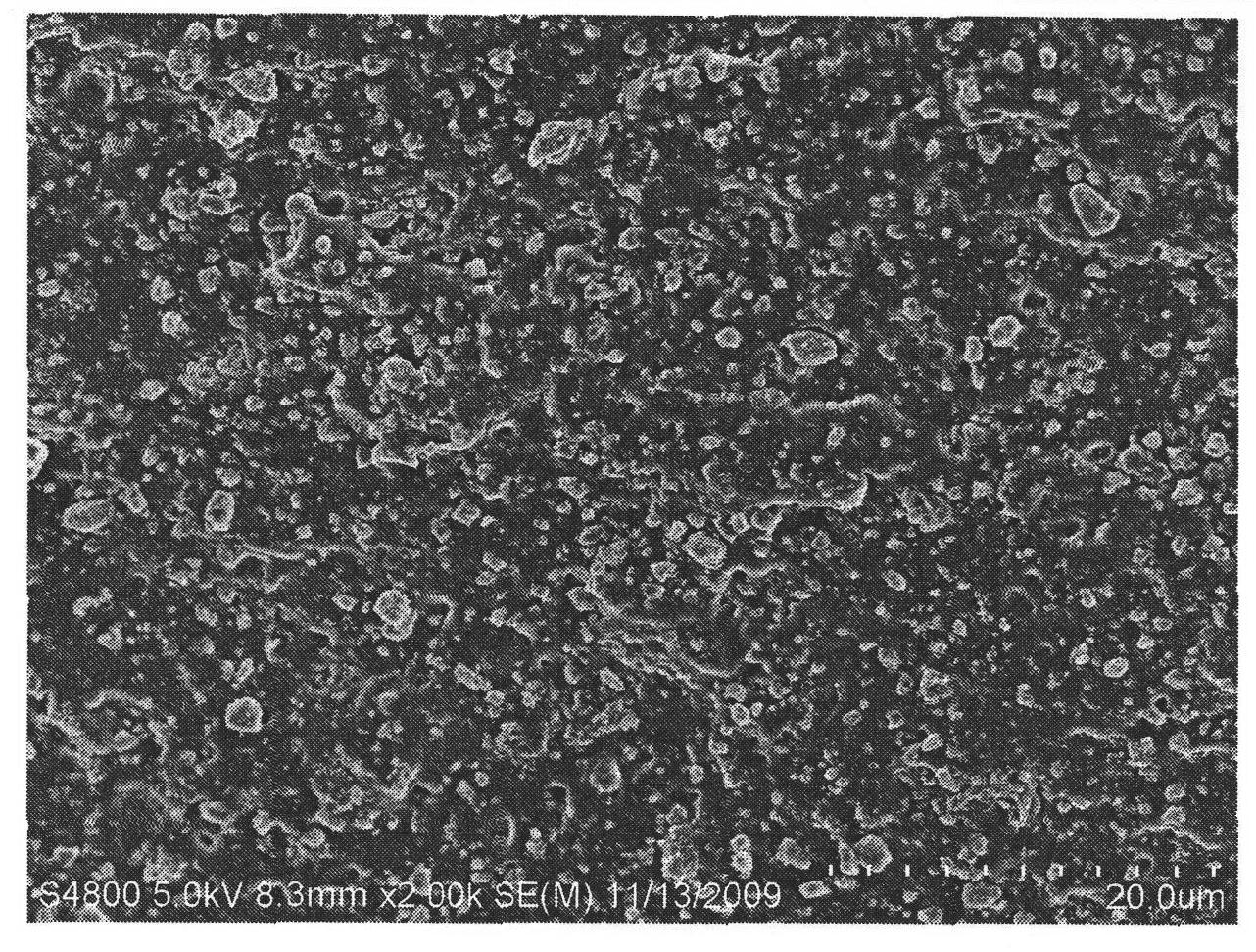

[0028] Example 1: Mix 1g of ZSM-5 molecular sieve with a particle size of 300nm and 60mL of n-heptane, stir at a low speed for 2h, add 0.1g of n-octyltriethoxysilane to react for 2h, then add 0.5g of Methylsiloxane (PDMS), after stirring at a low speed for 8 hours, add 4.5g of PDMS polymer and 25mL of n-heptane, and stir at a low speed for 4 hours to obtain a uniformly dispersed and very stable ZSM-5-PDMS composite material precursor solution, Finally, the film was scraped on the glass plate to obtain a highly dispersed organic-inorganic composite material of ZSM-5 molecular sieve doped with PDMS.

Embodiment 2

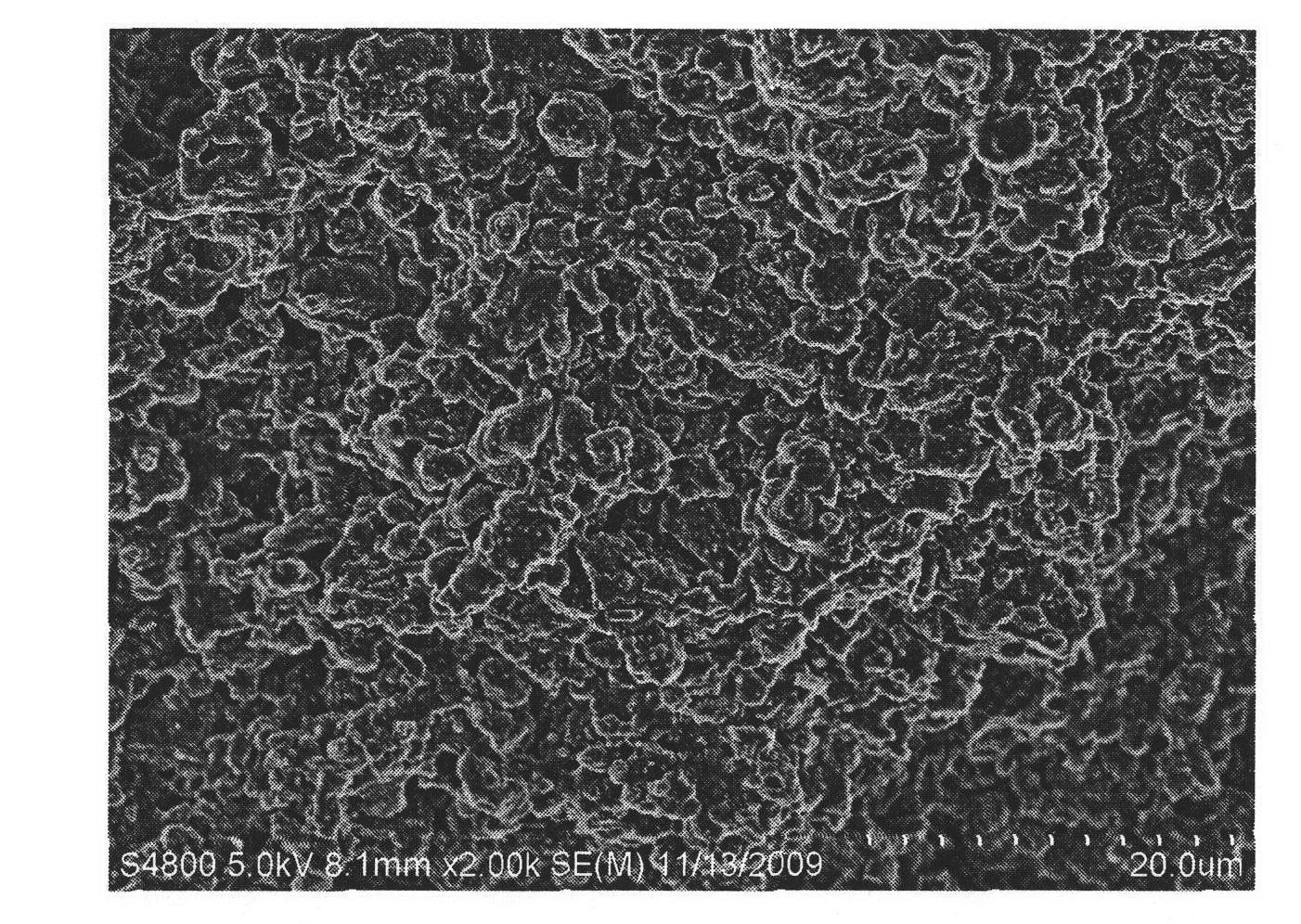

[0031] Example 2: Mix 0.5g of NaA molecular sieve with a particle size of 1 μm with 40mL of deionized water, stir at a low speed for 3 hours, add 0.5g of 3-aminopropyltriethoxysilane, and react for 1 hour, then add 0.5g of polyethylene Alcohol (PVA), after stirring at a low speed for 8 hours, add 4.5g of PVA polymer and 30mL of deionized water, and stir at a low speed for 4 hours to obtain a uniformly dispersed and stable NaA-PVA composite material precursor solution, and finally through the coating process, A highly dispersed NaA molecular sieve doped PVA organic-inorganic composite material can be obtained.

Embodiment 3

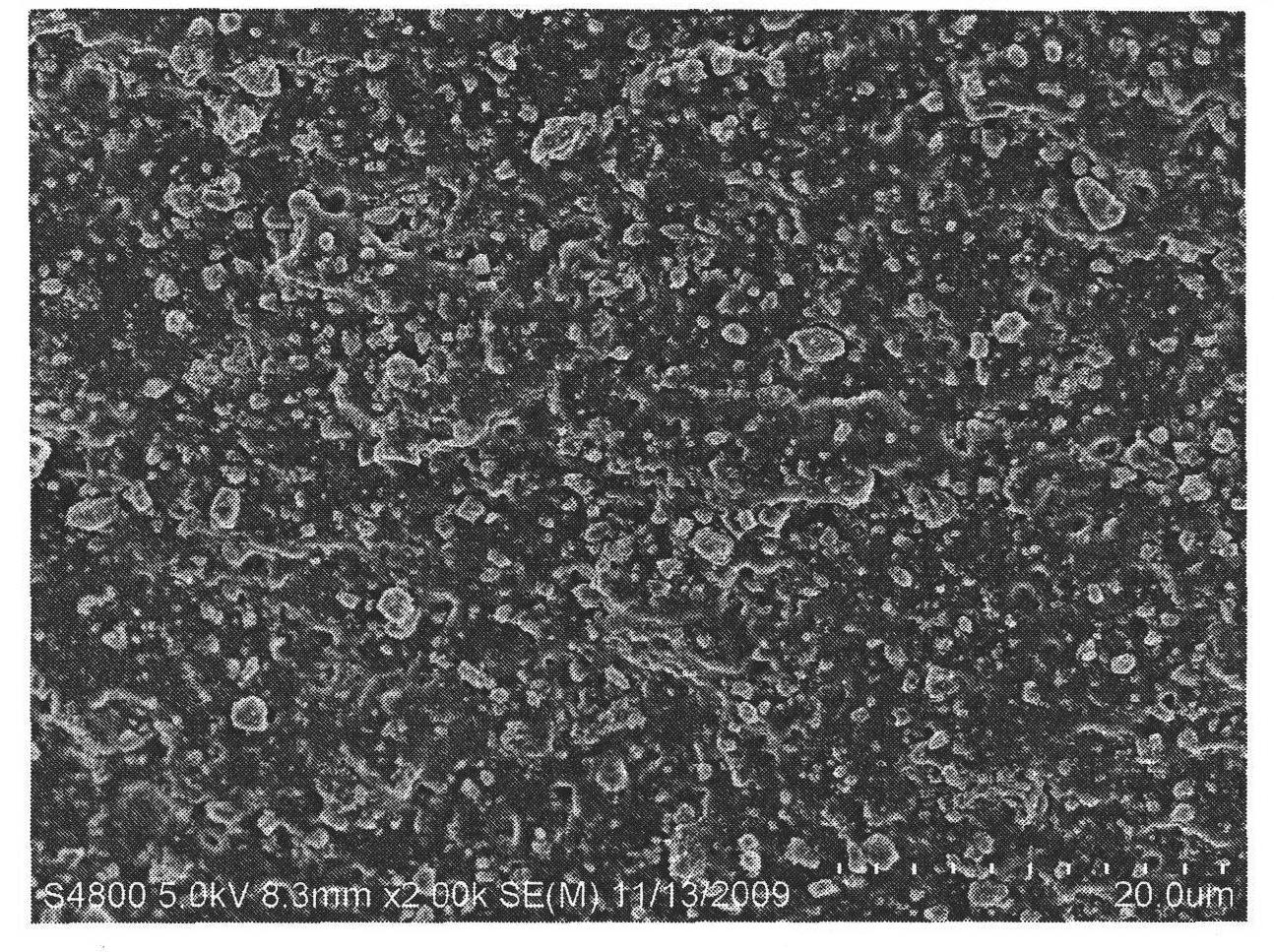

[0033] Example 3: Take 5g of titanium ore phase nano-scale barium, strontium, cobalt and iron with a particle size of 100nm and mix them with 60mL of dimethylformamide (DMF), stir at a low speed for 4h, then add 1g of diethylaminomethyltriethoxysilane to react After 1 hour, add 0.5 g of polyethersulfone (PES), stir at a low speed for 8 hours, then add 4.5 g of PES polymer and 20 mL of DMF, and stir for 4 hours at a low speed to obtain a uniformly dispersed and very stable barium-strontium-cobalt-iron-PES composite material The precursor liquid, and finally through extrusion molding, can get highly dispersed barium strontium cobalt iron doped PES organic-inorganic composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com