Layered polypropylene/graphene heat-conducting composite material and preparation method thereof

A thermally conductive composite material, graphene technology, applied in coatings and other directions, can solve the problems of insignificant improvement of thermal conductivity, high dispersion cost of graphene, damage to PP mechanical properties, etc., to achieve excellent thermal conductivity/heat dissipation and mechanical properties, good Conducive to large-scale mass production and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

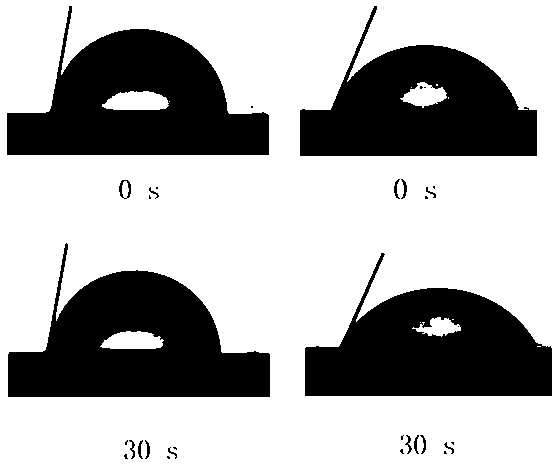

Image

Examples

Embodiment 1

[0032] The preparation method of the layered polypropylene / graphene thermally conductive composite material provided by the present embodiment comprises the following steps:

[0033] (1) Using the PP film as the base material, modifying dopamine onto the surface of the PP film, forming a polydopamine layer on the surface through a self-polymerization process, and performing hydrophilic modification on the surface of the PP film to obtain a surface-modified PP film; the PP The thickness of the film is 10μm~1mm;

[0034] The specific steps of the self-polymerization modification process on the surface of the PP film with dopamine are:

[0035] (11) Prepare tris (Tris) buffer solution with a concentration of 0.01mol / L to 0.1mol / L, preferably 0.01mol / L;

[0036] (12) Use hydrochloric acid to adjust the pH value of the buffer solution, 8.0-8.5, preferably 8.5; disperse dopamine in the buffer solution, the content is 1g / L-3g / L, preferably 2g / L;

[0037] (13) Immerse the PP film in...

Embodiment 2

[0049] The preparation method and material of the layered polypropylene / graphene thermally conductive composite material provided in this embodiment are basically the same as in Example 1, except that:

[0050] (1) Use PP film as the base material, modify dopamine on the polypropylene film, and form a polydopamine layer on the surface of polypropylene: the thickness of the polypropylene film is 20 μm, and the tris (Tris) buffer solution is prepared at a concentration of 0.01 mol / L, use hydrochloric acid to adjust the pH value of the buffer to 8.5; disperse dopamine in the buffer with a content of 2g / L; immerse a polypropylene film with a thickness of 20 μm in the buffer, adjust the temperature to 60°C, and stir slowly Installed under the tower, soaked for 24h, the gained polydopamine modified polypropylene film was rinsed repeatedly with deionized water and ethanol, and dried at room temperature;

[0051] (2) Graphene oxide is covered on the modified PP plastic film to form a ...

Embodiment 3

[0055] The preparation method and material of the layered polypropylene / graphene thermally conductive composite material provided in this embodiment are basically the same as those in Embodiments 1 and 2, except that:

[0056] (1) Use PP film as the base material, modify dopamine on the polypropylene film, and form a polydopamine layer on the surface of polypropylene: the thickness of the polypropylene film is 20 μm, and the tris (Tris) buffer solution is prepared at a concentration of 0.01 mol / L, use hydrochloric acid to adjust the pH value of the buffer to 8.5; disperse dopamine in the buffer with a content of 2g / L; immerse a polypropylene film with a thickness of 20 μm in the buffer, adjust the temperature to 60°C, and stir slowly Put it under the tower, soak for 24 hours, and the obtained polydopamine-modified polypropylene film is washed repeatedly with deionized water and ethanol, and dried at room temperature.

[0057] (2) Graphene oxide is covered on the modified PP pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com