Electromagnetically separated and closed yarn storage device and yarn detection method thereof

A technology of electromagnetic clutch and detection method, which is applied in the fields of optical device exploration, textile and papermaking, weft knitting, etc. Construct simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

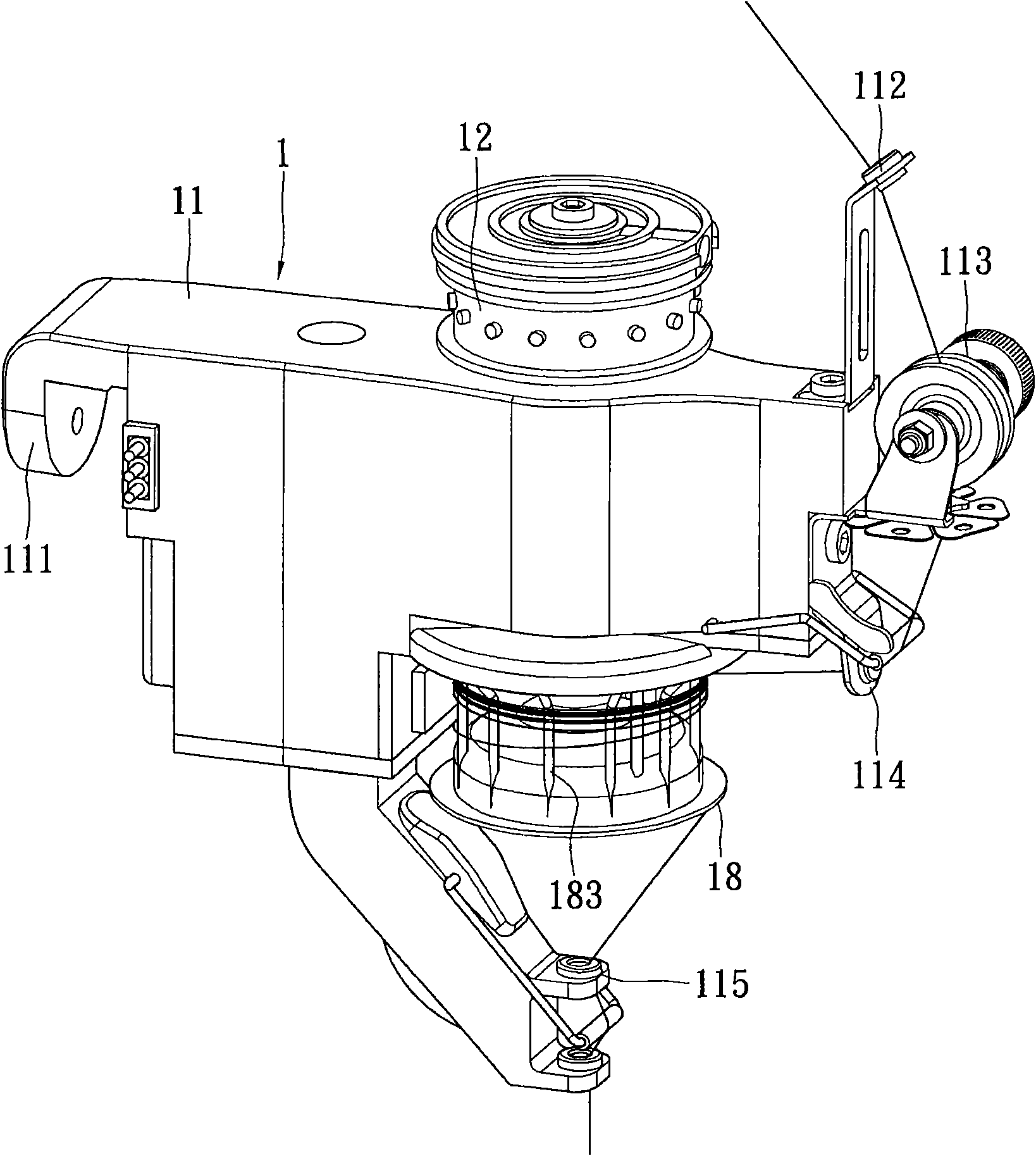

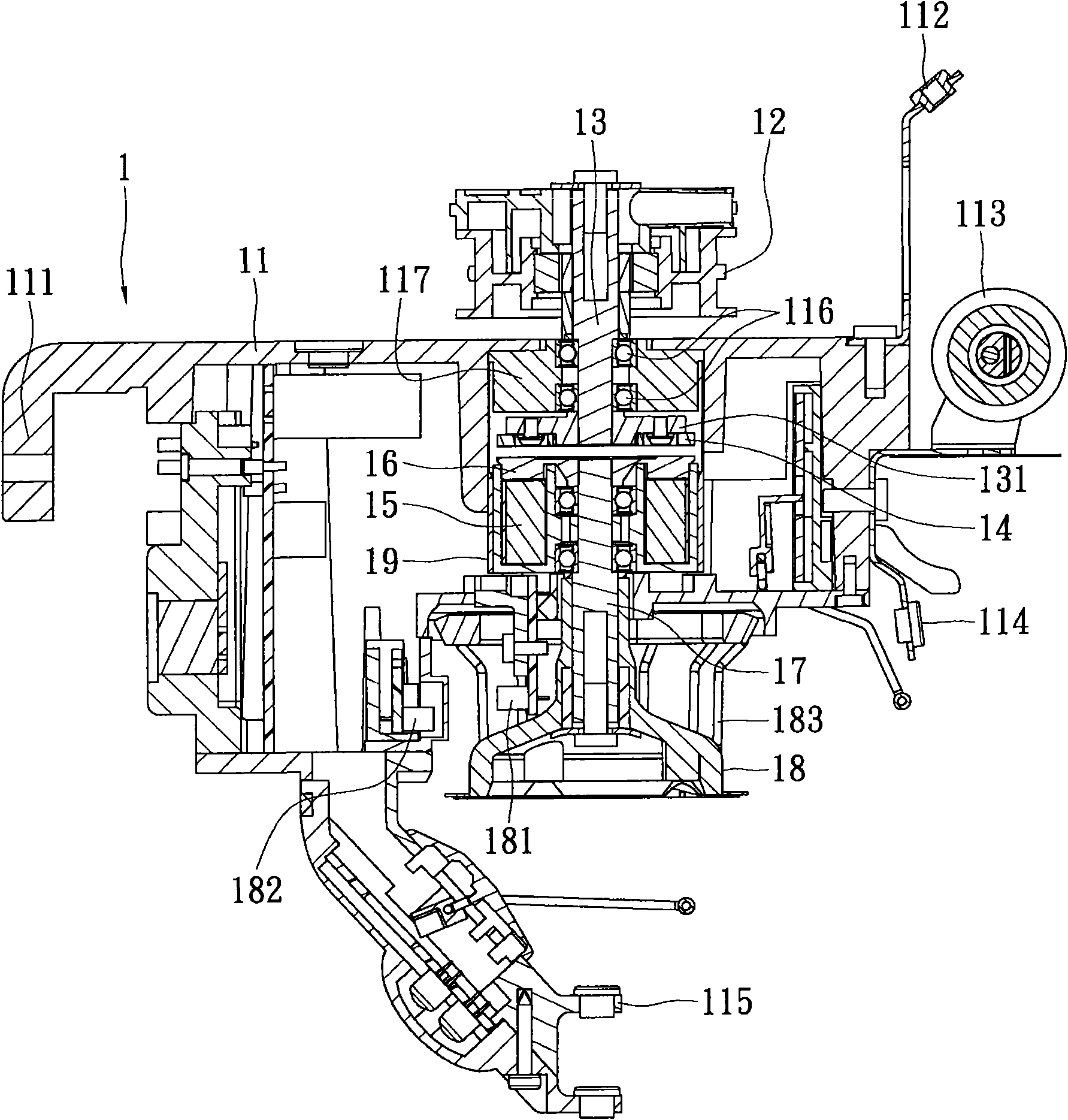

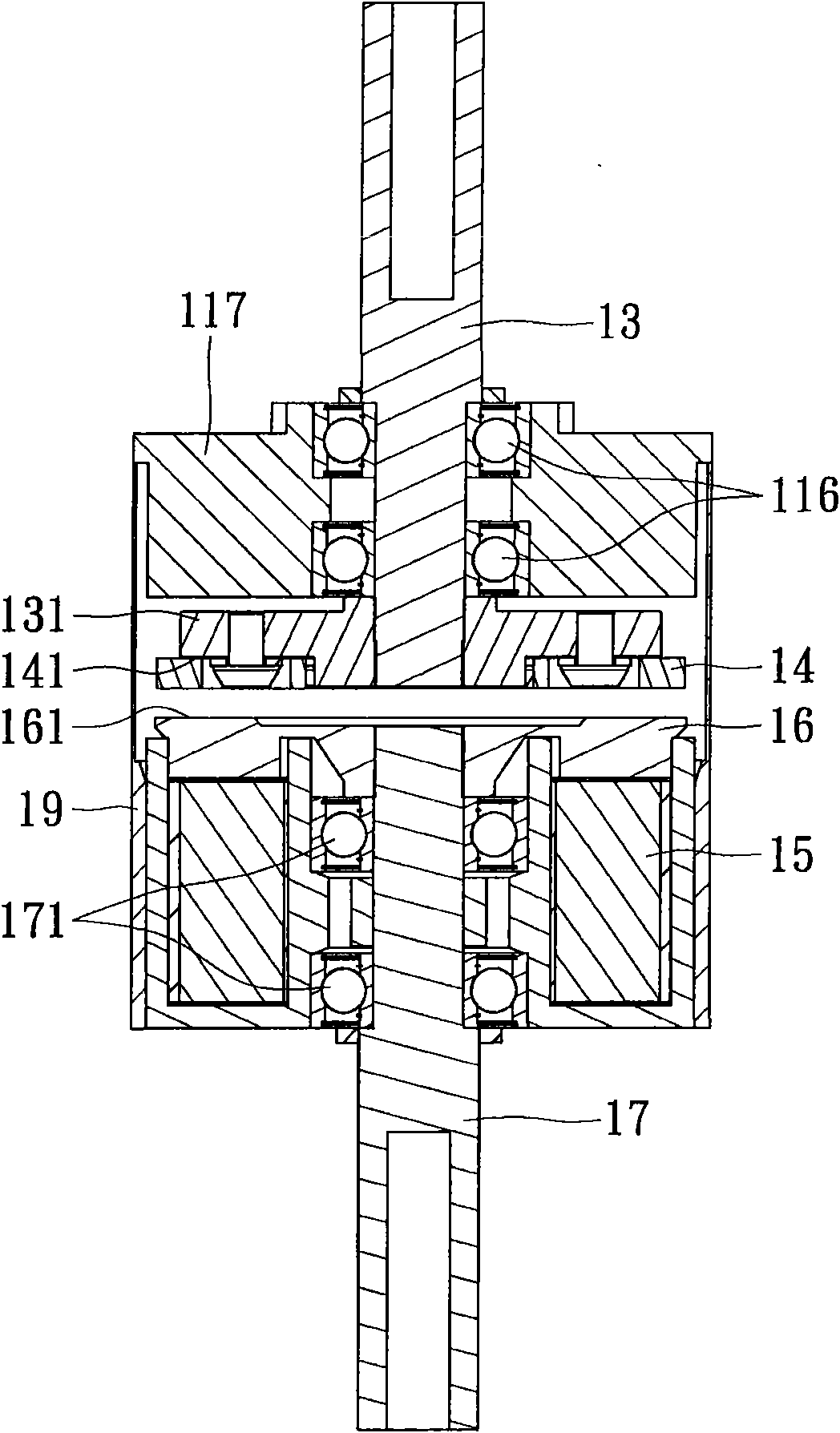

[0047] see figure 1 , figure 2 , Figure 2A , image 3 and Figure 3A , the present invention provides an electromagnetic clutch yarn storage device, the yarn storage device 1 includes a body 11, a pulley 12, a first transmission shaft 13, a driving disc 14, an electromagnetic coil 15, a driven disc 16 , a second drive shaft 17 and a yarn storage wheel 18.

[0048] One end of the main body 11 has a fixing portion 111 , and the fixing portion 111 can be locked and fixed to a proper position on the knitting machine with screws. The body 11 is also provided with several yarn guides 112, 113, 114, 115, which can be used to guide yarns.

[0049] The center of the belt pulley 12 is connected to the upper end of the first transmission shaft 13, the belt pulley 12 and the first transmission shaft 13 can rotate synchronously, and the two bearings 116 are preset on a fixed seat 117, and then the fixed seat 117 is fixed on the body 11 , the bearings 116 are disposed on the body 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com