Installation structure for cam shaft and timing gear

A timing gear and installation structure technology, applied in the direction of belt/chain/gear, valve device, hoisting device, etc., can solve the problems of stress concentration of positioning keys, large torque of bolts, scrapped engine, etc. The effect of loosening and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

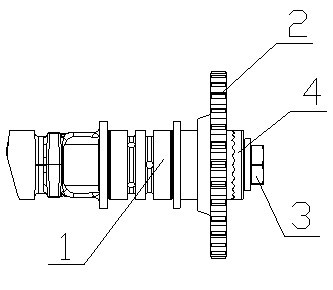

[0019] Such as figure 1 As shown, the camshaft timing gear installation structure of the present invention includes a camshaft 1, a timing gear 2, a bolt 3, and a gasket 4. Between timing gear 2 and bolt 3.

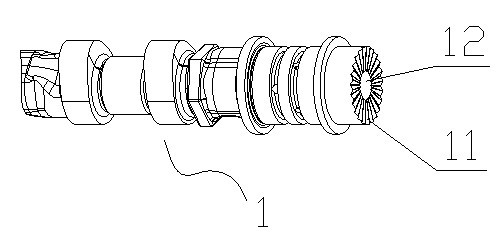

[0020] Such as figure 2 As shown, the surface of one end of the camshaft 1 is provided with a radial spline 11 , and the center of the end is provided with an axial screw hole 12 for installing the bolt 3 .

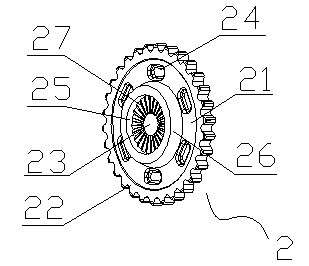

[0021] Such as image 3 , 4 , 5, the timing gear 2 is composed of three parts: a wheel disc 21, a gear tooth 22 and a shaft hole 23, and the outer periphery of the wheel disc 21 is provided with gear teeth 22, which are used to cooperate with the timing chain, wherein the number of gear teeth 22 It can be arranged according to actual needs. The wheel disc 21 between the gear teeth 22 and the shaft hole 23 is concave, and there are a plurality of arc-shaped weight-reducing holes 24 on the wheel disc cloth, and the weight-reducing holes 24 are evenly distributed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com