Coal evaluation method and system

An evaluation method and technology for coal types, which can be applied to measurement devices, instruments, scientific instruments, etc., and can solve the problems of inaccurate simulation of industrial devices, long evaluation period, and large investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

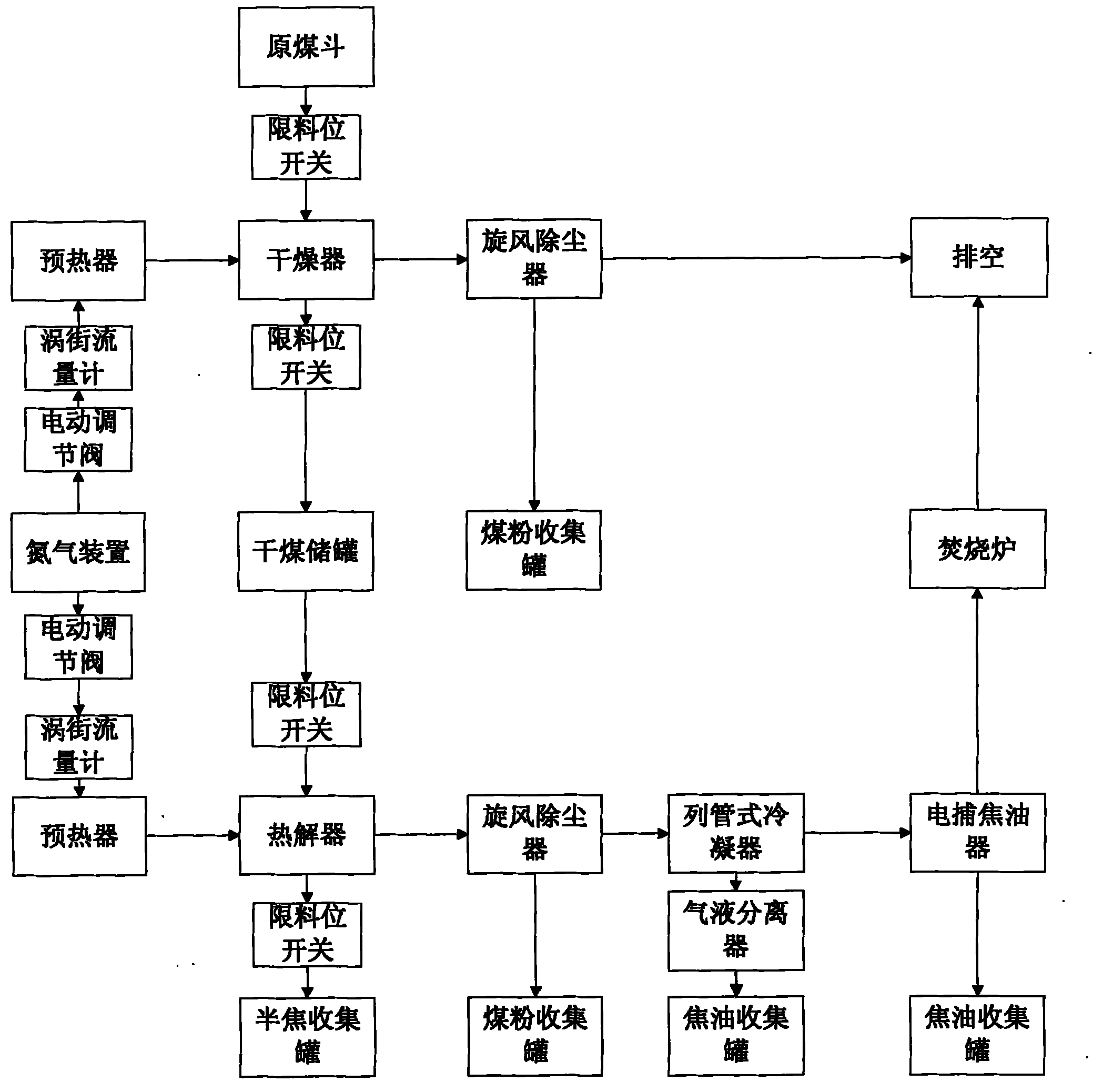

Method used

Image

Examples

Embodiment 1

[0061] Examples of coal type evaluation in Huolinhe Coal Mine, Inner Mongolia:

[0062] Put 10kg of coal samples from the Huolinhe mining area in Inner Mongolia into the raw coal hopper of the coal type evaluation system of the present invention, at first according to the properties of the coal, the control system determines the size of the required gas flow, and first in the control computer of the SPU system Input dry gas flow rate 15m 3 / h, 16m 3 / h, 18m 3 / h, 20m 3 / h, drying gas temperature 150°C, 180°C, 200°C, 220°C, 250°C, when the gas flow rate measured by the vortex flowmeter reaches the set flow rate, and the temperature measured by the thermometer at the inlet of the dryer reaches the set temperature, the control is turned on The material-limiting level switch under the raw coal hopper unloads the coal sample into the dryer of the coal type evaluation system of the present invention for drying, and the drying time is 80min, 90min, 100min, 110min, 120min, and 130m...

Embodiment 2

[0069] Example of coal type evaluation in Xiaonangou Coal Mine, Shaanxi:

[0070] Pack 10kg of coal samples from the Xiaonangou mining area in Shaanxi into the coal type evaluation system of the present invention, first set the gas flow rate at 15m according to the properties of the coal 3 / h, 16m 3 / h, 18m 3 / h, 20m 3 / h, the drying gas temperature is 150°C, 180°C, 200°C, 230°C, 250°C, and the moisture content is measured respectively when the drying time is 80min, 90min, 100min, 110min, 120min, and 130min. When the nitrogen drying temperature is 230 ℃, the flow rate of dry nitrogen is 16m 3 / h, and the moisture content of the coal sample when the drying time is 100min is 5.8% (below 6%), and the corresponding parameters are determined to be the best drying experimental parameters. Also set the gas flow rate to 13m 3 / h, 14m 3 / h, 15m 3 / h, 16m 3 / h, the pyrolysis gas temperature is 550°C, 590°C, 620°C, 650°C, when the pyrolysis time is 40min, 50min, 60min, 70min, 80m...

Embodiment 3

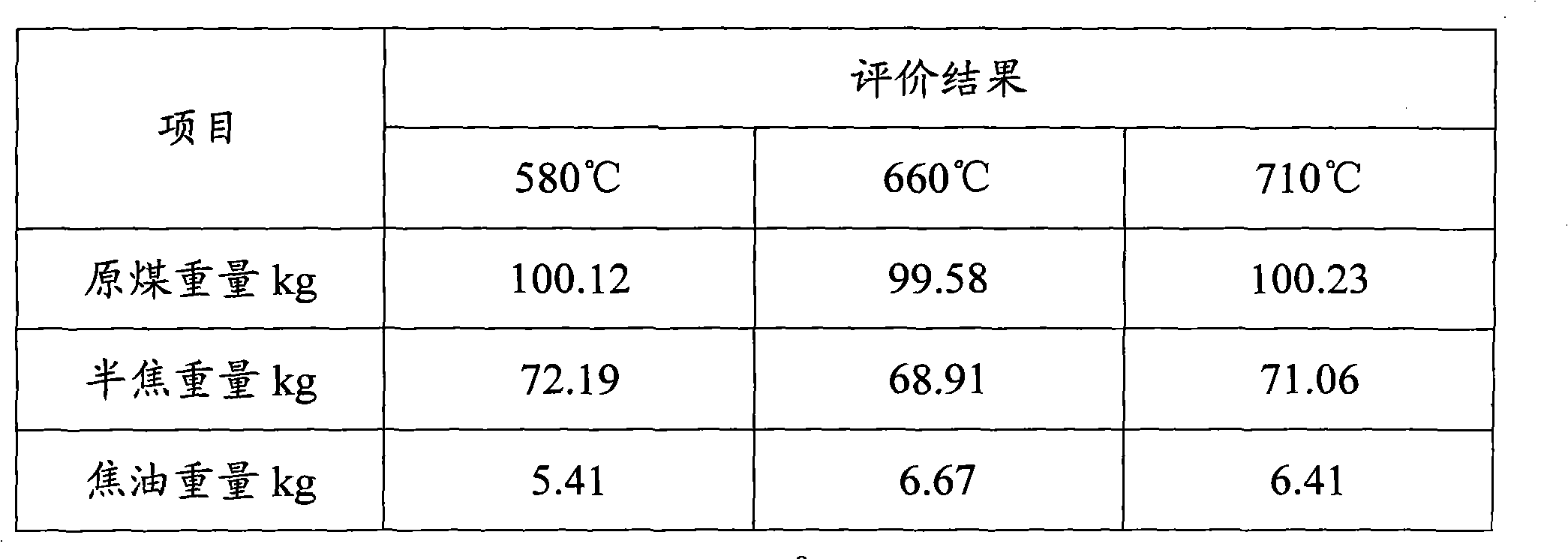

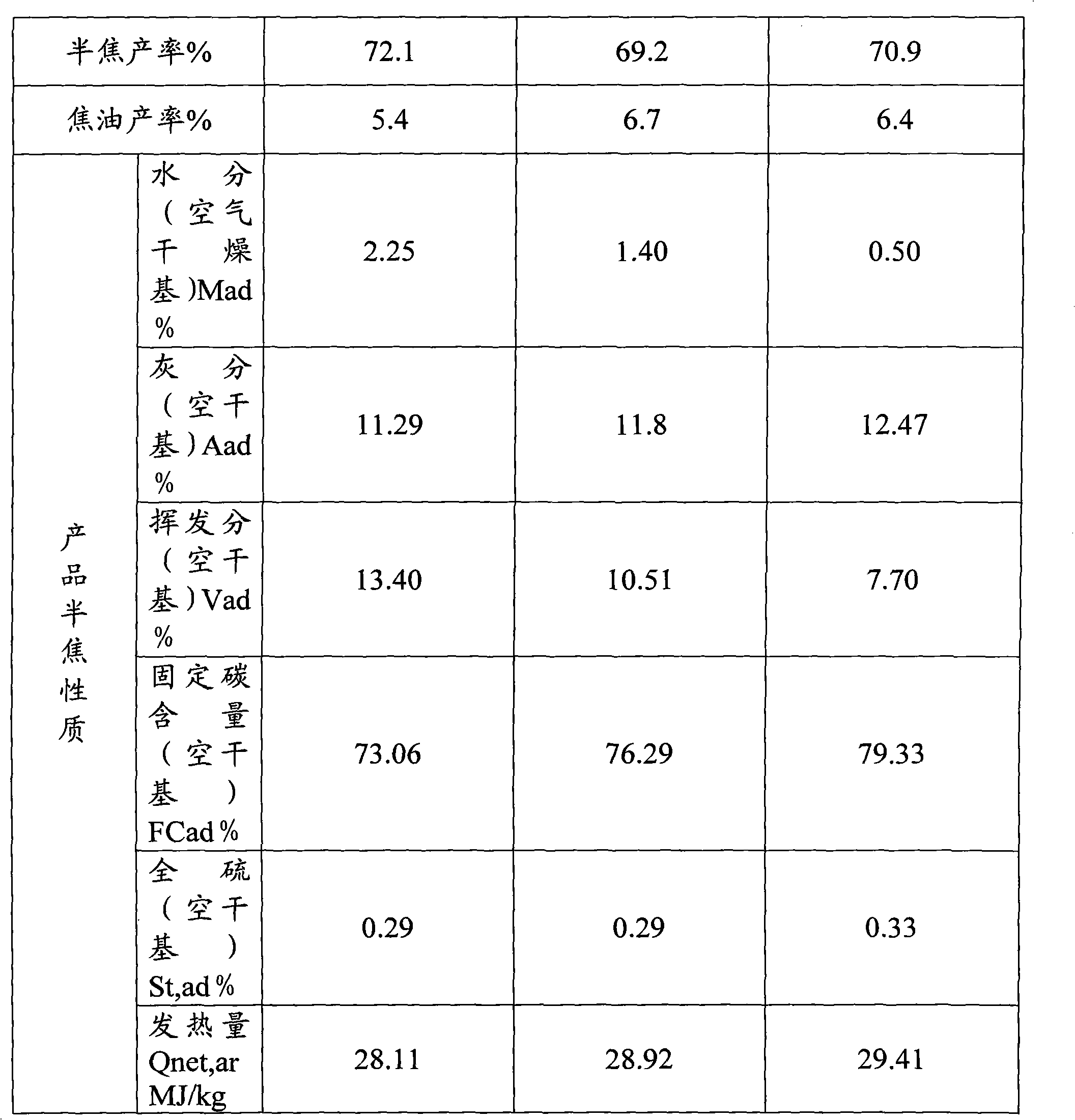

[0074] Example of coal type evaluation in Yongfeng Coal Mine, Yunnan:

[0075] First, according to the nature of the coal, first set the gas flow rate to 12m 3 / h, 15m 3 / h, 16m 3 / h, 18m 3 / h drying gas temperature 150°C, 180°C, 200°C, 220°C, 250°C, put 10kg of coal samples from Yongfeng Coal Mine in Yunnan into the coal type evaluation system of the present invention, and the drying time is 100min, 110min, 120min, 130min respectively , 140min, and 150min to measure the moisture content of the coal sample, and the dry gas temperature is 180°C, and the dry nitrogen flow rate is 15m 3 , when the drying time is 130min, the moisture content of the coal sample is determined to be 5.9% (below 6%), and the corresponding parameters are determined to be the best drying experimental parameters. Set the gas flow rate to 8m in turn 3 / h, 10m 3 / h, 12m 3 / h, 14m 3 / h, 16m 3 / h, pyrolysis gas temperature 580 ℃, 600 ℃, 660 ℃, 680 ℃, 700 ℃, when the pyrolysis time is respectively 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com