Sewing-free upper vamp and manufacture method thereof

A manufacturing method and technology without sewing, which is applied to shoe uppers, footwear, shoe eyelets, etc., can solve the problems of complex manufacturing process, high production cost, and high difficulty, and achieve low processing cost, high production efficiency, and reduced processing difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

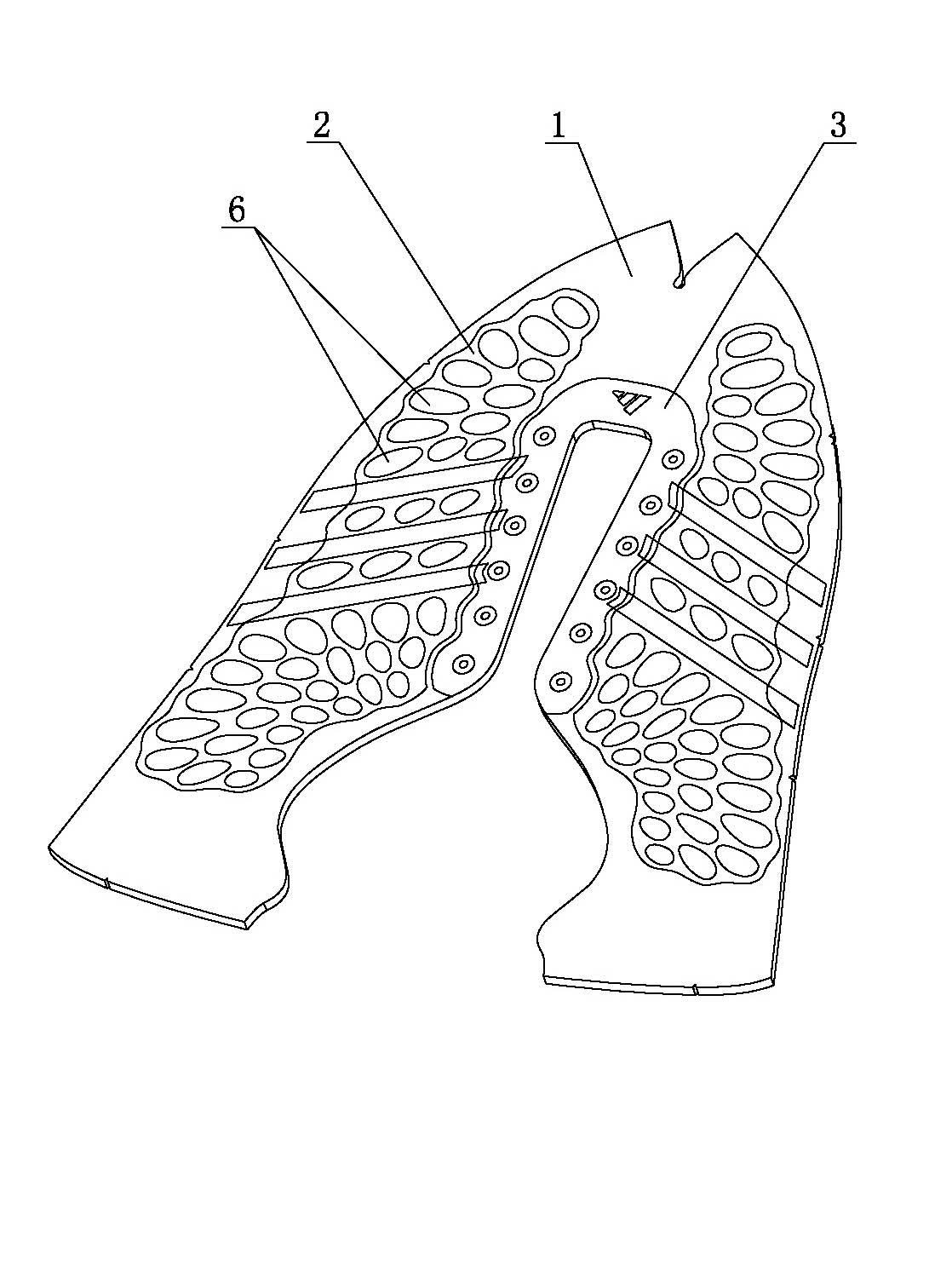

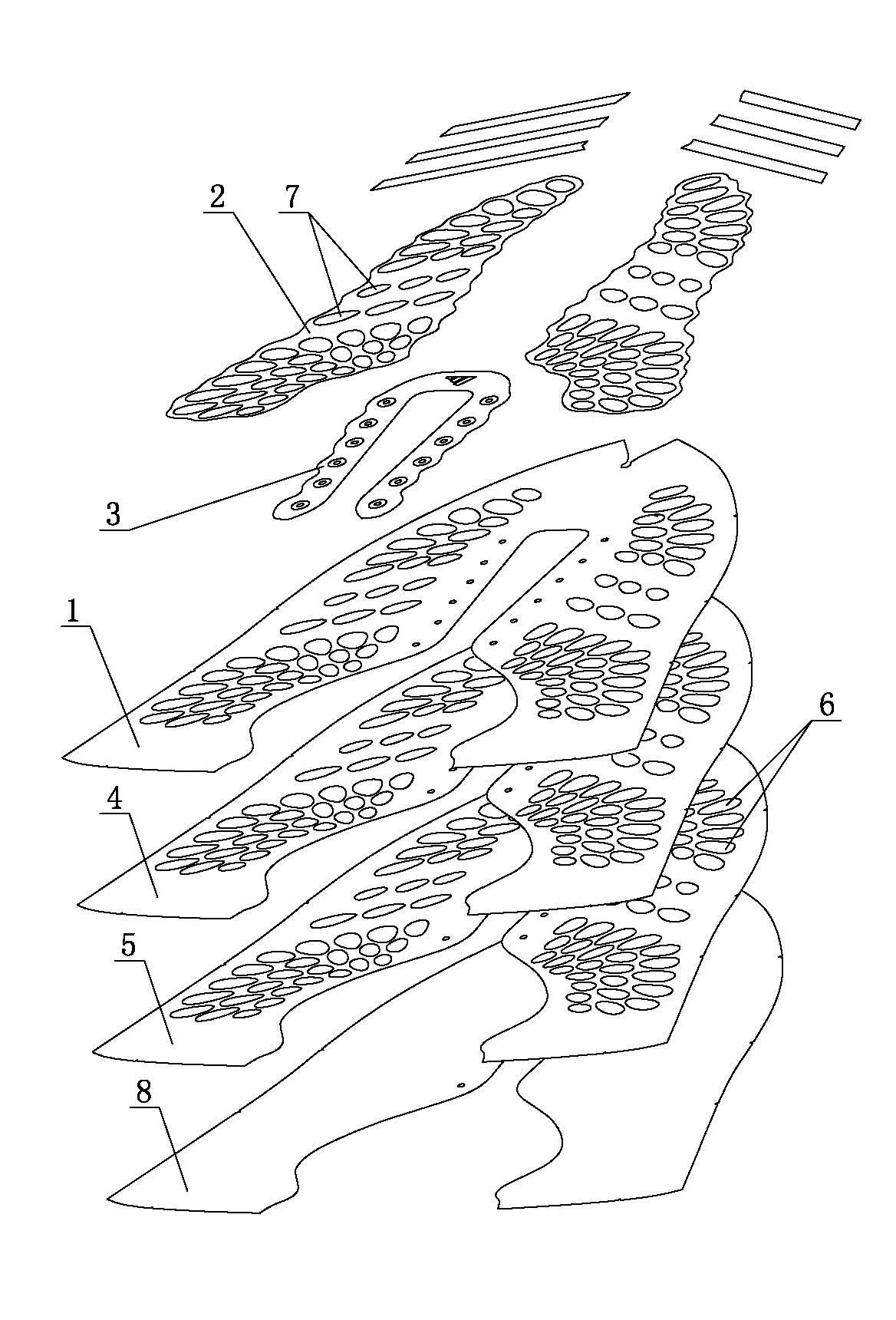

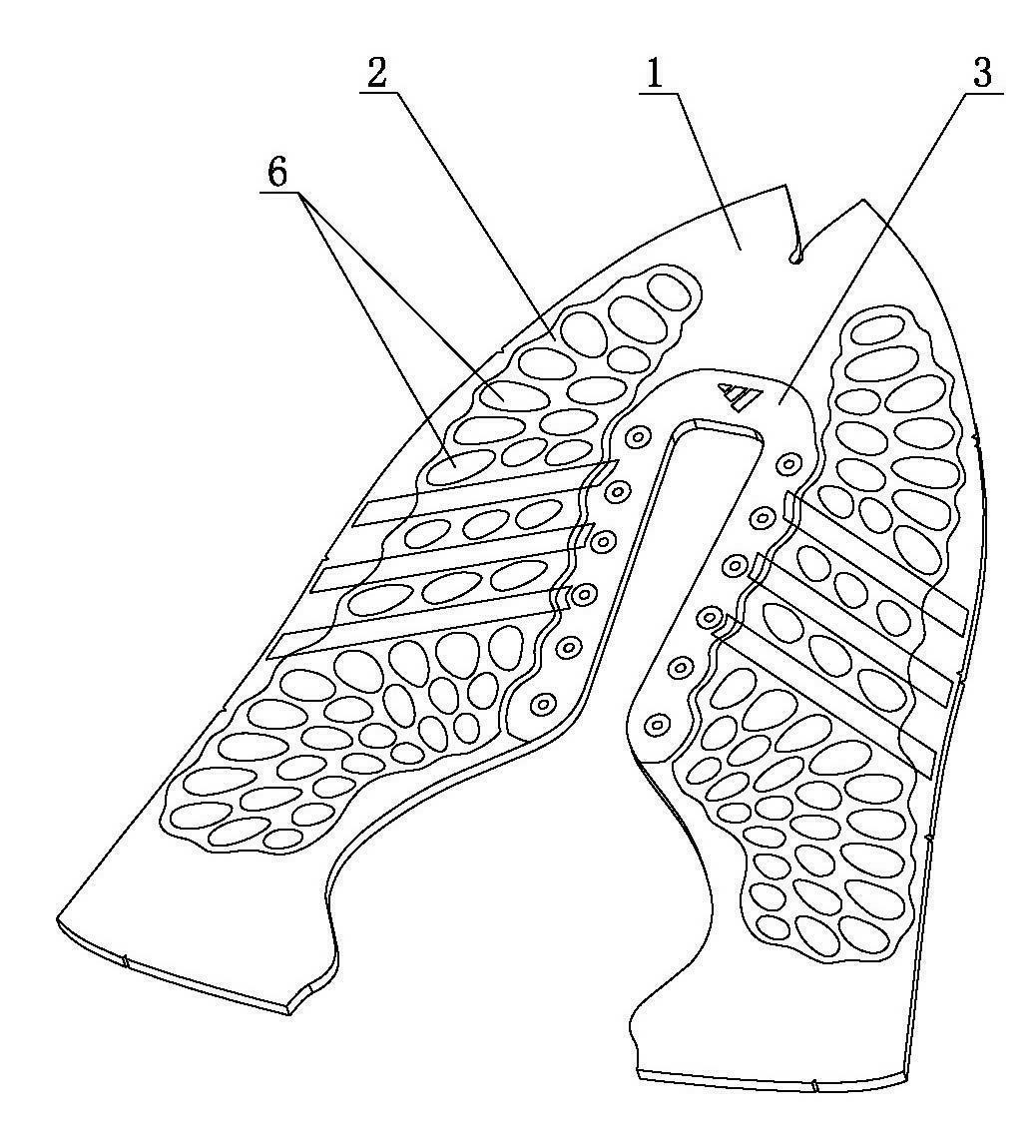

[0034] Such as figure 1 and figure 2 As shown, a non-sewed vamp includes a vamp material 1 and a decorative attachment 2 arranged on the upper surface of the vamp material 1, the upper surface of the vamp material 1 is provided with a shoe eyelet 3, and also includes a thermal Melt adhesive layer 4 and air-permeable layer 5, the upper surface of hot-melt adhesive layer 4 is bonded with the lower surface of shoe upper material 1, the lower surface of hot-melt adhesive layer 4 is bonded with the upper surface of air-permeable layer 5, the air-permeable layer 5 The lower surface is bonded to the upper surface of the inner material layer 8 . The present invention welds a variety of different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com