Dissimilar metal connection method for copper-aluminum pipe

A connection method and technology of dissimilar metals, applied in metal processing equipment, welding equipment, high-frequency current welding equipment, etc., can solve the problems of reducing the mechanical properties of the weld, expensive cesium fluoroaluminate flux, and increasing manufacturing costs. Achieve the effects of improving air tightness and fatigue resistance, good controllability of heating temperature, and low heating peak temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

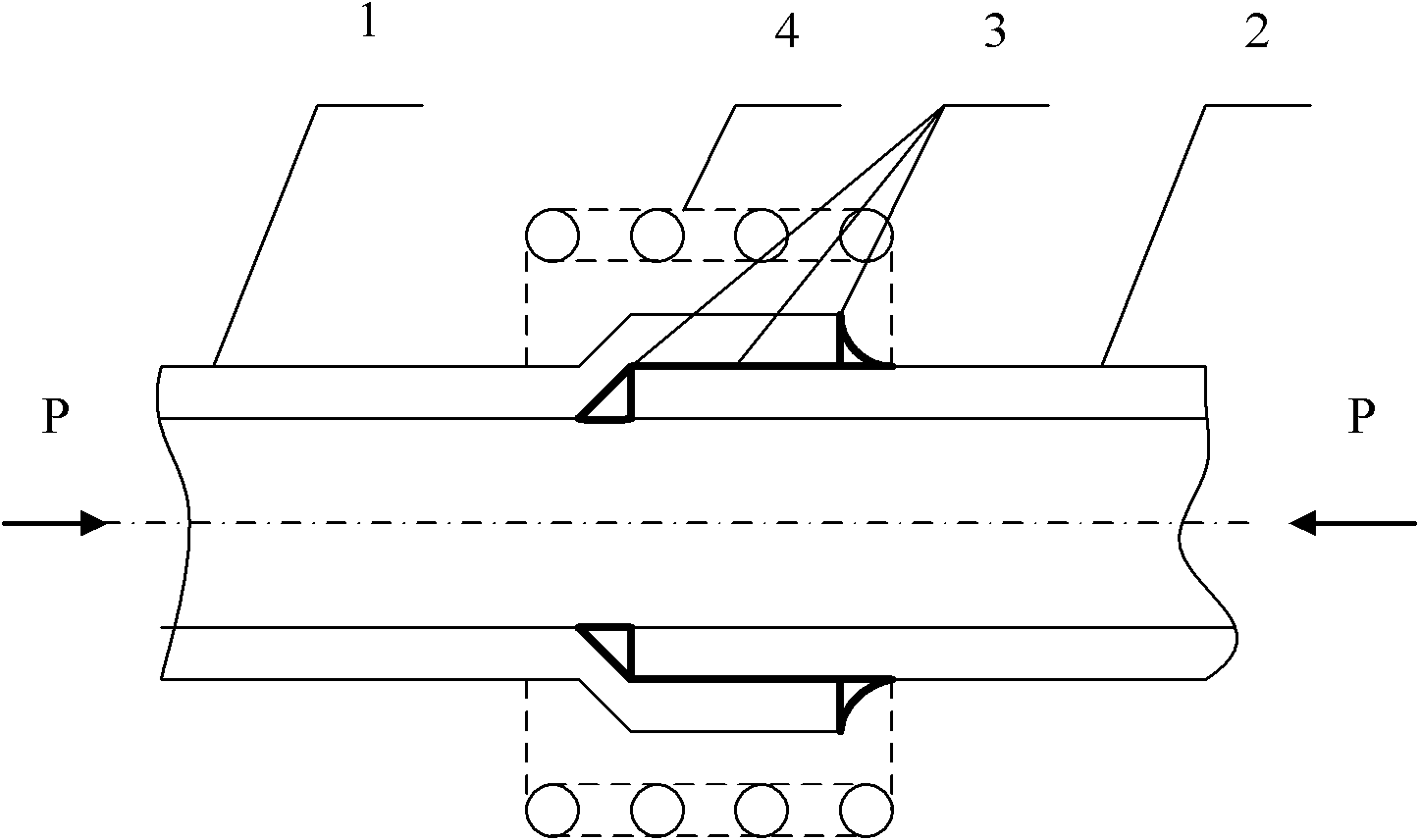

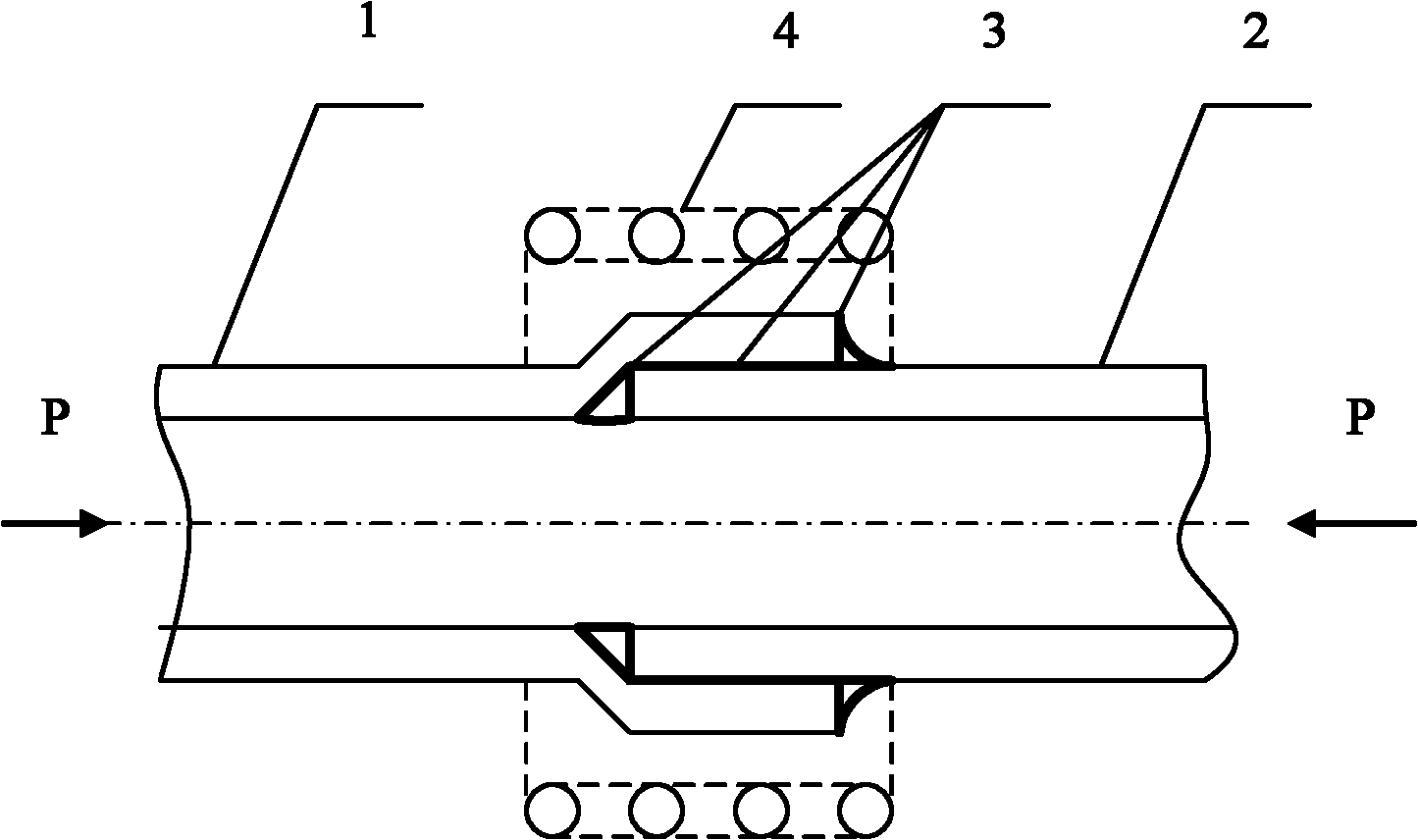

[0018] A copper-aluminum pipe dissimilar metal connection method, such as figure 1 as shown,

[0019] 1) Use copper pipe 1 and aluminum pipe 2 each with an outer diameter of Φ10mm and a wall thickness of 0.8mm, and expand on the surface to be connected of the copper pipe, so that the inner diameter of the expanded part 3 is Φ10mm, take a positive tolerance, and expand The depth is 8mm (that is, the lap length). The outer diameter of the aluminum tube takes a negative tolerance.

[0020] 2) Immerse the surface to be connected of the copper tube 1 into trimethyl borate liquid flux, and coat the surface to be connected (outer surface) of the aluminum tube 2 with potassium fluoroaluminate paste flux. Then insert the aluminum pipe 2 in the copper pipe 1.

[0021] 3) Put the assembled joint into the inductor 4 for heating. When the potassium fluoroaluminate flux melts (560°C, controlled by a temperature controller), apply an axial pressure (6MPa) and maintain it for 1s, then rel...

Embodiment 2

[0024] A copper-aluminum pipe dissimilar metal connection method, such as figure 1 as shown,

[0025] 1) Use a section of copper tube 1 and aluminum tube 2 with an outer diameter of Φ30mm and a wall thickness of 1.2mm, and expand on the surface to be connected of the copper tube, so that the inner diameter of the expanded part 3 is Φ30mm, take a positive tolerance, and expand The depth is 15mm (that is, the lap length). The outer diameter of the aluminum tube takes a negative tolerance.

[0026] 2) Immerse the surface to be connected of the copper tube 1 into trimethyl borate liquid flux, and coat the surface to be connected (outer surface) of the aluminum tube 2 with potassium fluoroaluminate paste flux. Then insert the aluminum pipe 2 in the copper pipe 1.

[0027] 3) Put the assembled joint into the inductor 4 for heating. When the potassium fluoroaluminate flux melts (560°C, controlled by a temperature controller), apply an axial pressure (8MPa) and maintain it for 2s,...

Embodiment 3

[0030] A copper-aluminum pipe dissimilar metal connection method, such as figure 1 as shown,

[0031] 1) Use copper tube 1 and aluminum tube 2 each with an outer diameter of Φ60mm and a wall thickness of 3.0mm, and expand on the surface to be connected of the copper tube 1, so that the inner diameter of the flared part 3 is Φ60mm, take a positive tolerance, expand The mouth depth is 25mm (that is, the lap length). The outer diameter of the aluminum tube takes a negative tolerance.

[0032] 2) Immerse the surface to be connected of the copper tube 1 into trimethyl borate liquid flux, and coat the surface to be connected (outer surface) of the aluminum tube 2 with potassium fluoroaluminate paste flux. Then insert the aluminum pipe 2 in the copper pipe 1.

[0033] 3) Put the assembled joint into the inductor 4 for heating. When the potassium fluoroaluminate flux melts (560°C, controlled by a temperature controller), apply axial pressure (9MPa) and maintain it for 3s, then rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com