Preparation method of reclaimed self-heat-insulation building block

A technology of self-insulating blocks and waste utilization, which is applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of unreliable connection between block base and core material, cumbersome production process, long production process, etc., and achieve simple and clear production process , Easy construction and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is further described below in conjunction with embodiment and accompanying drawing.

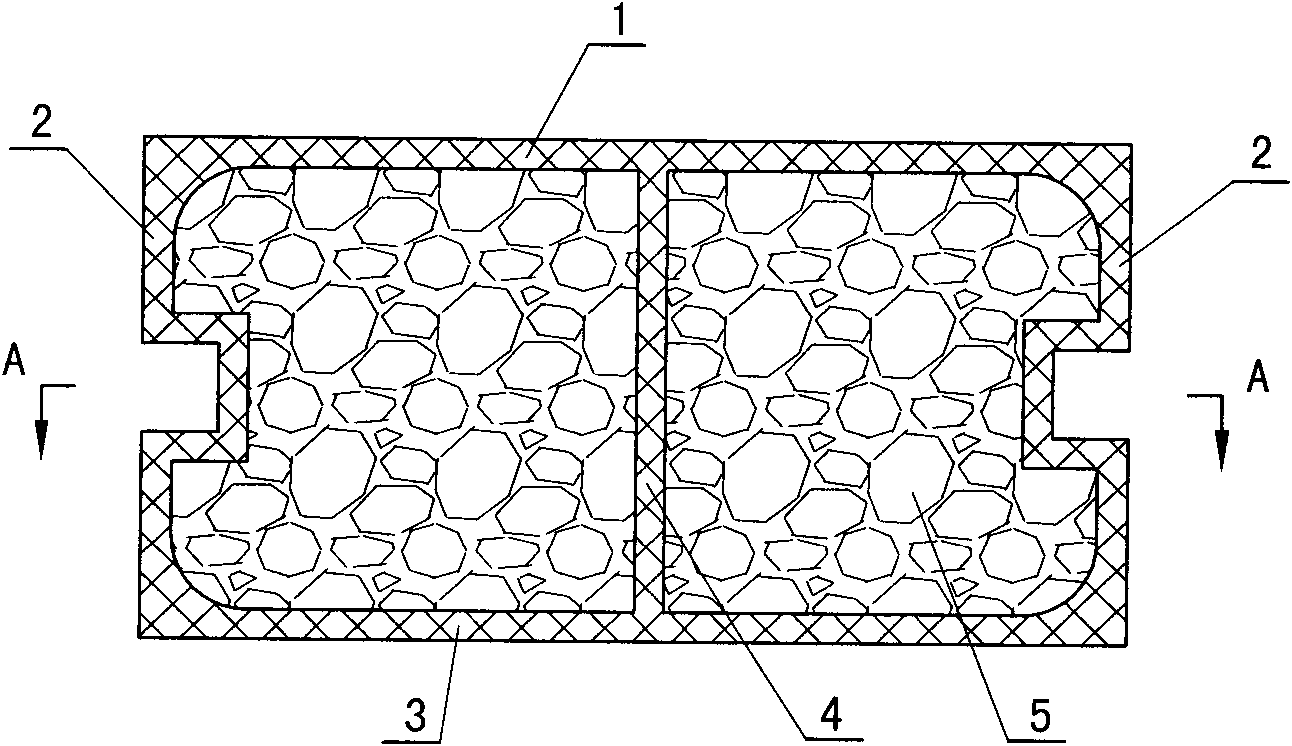

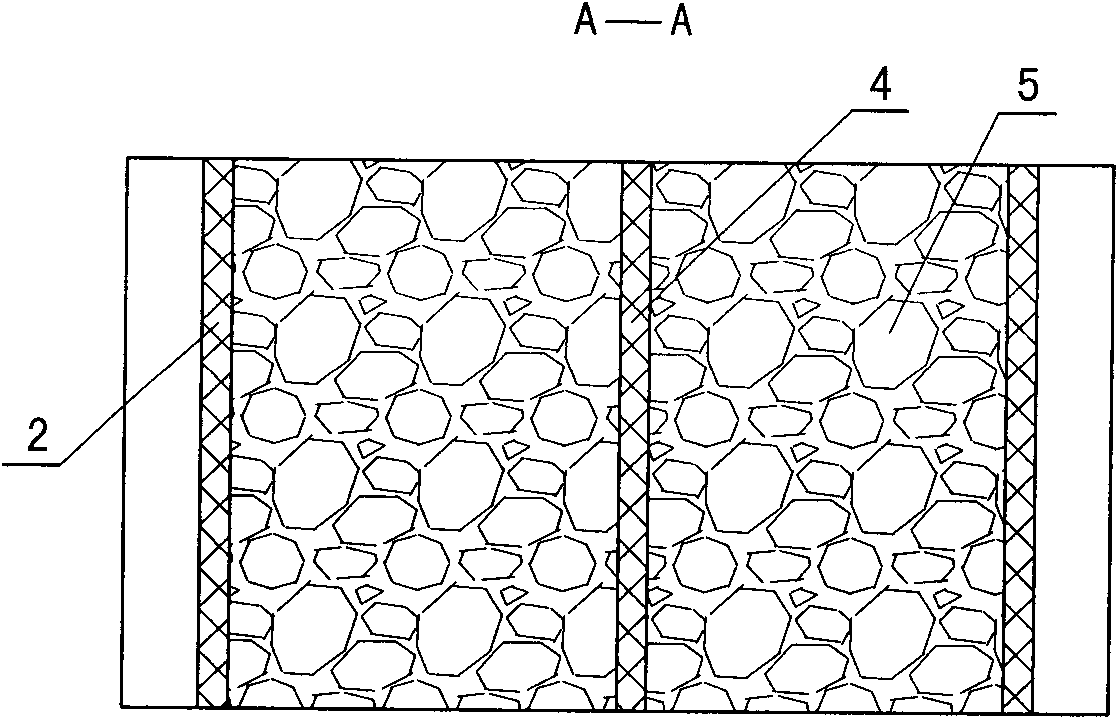

[0023] see figure 1 , figure 2

[0024] One of the blocks prepared by the present invention is constructed by an outer wall 1, an inner wall 3, and an end rib 2 into a block base body with a cavity, and an inner rib 4 is arranged in the cavity, and the two ends of the inner rib 4 are connected with the outer wall 1, the end rib 2, respectively. The inner side of the inner wall 3 is connected, and the core block 5 is filled in the cavity.

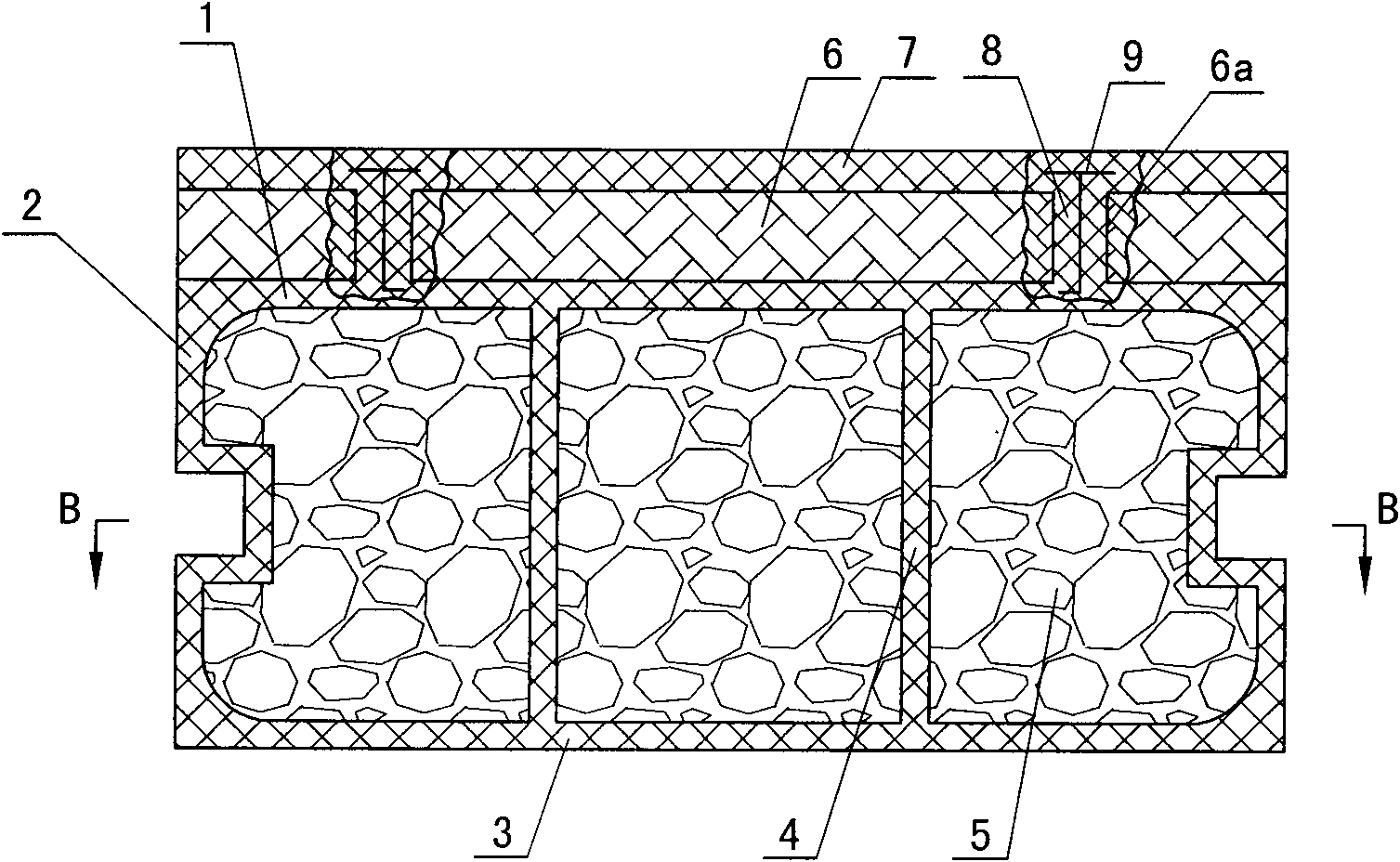

[0025] see image 3 , Figure 4

[0026] The second block prepared by the present invention consists of an outer wall 1, an inner wall 3, and an end rib 2 to form a block matrix with a cavity, and an inner rib 4 is arranged in the cavity, and the two ends of the inner rib 4 are connected to the outer wall 1 and the inner wall respectively. The inside of 3 is connected, and the core block 5 is filled in the cavity, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com