Machine neck of vacuum brick extruding machine

A technology of vacuum brick extruder and machine neck, which is applied to ceramic forming machines and manufacturing tools, etc. It can solve problems such as poor lubrication and adjustment of rotary motion to linear motion, and achieve the effects of improving yield, increasing use efficiency, and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

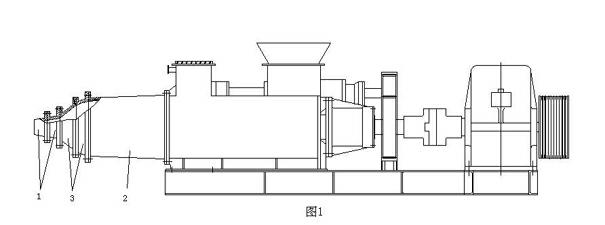

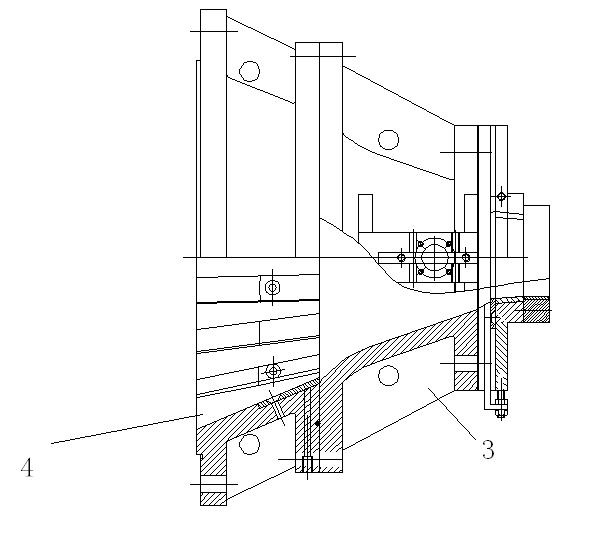

[0024] figure 1 Shown is a schematic diagram of the whole structure of the vacuum tile extruder. The vacuum tile extruder includes a mud cylinder 2. At the discharge end of the mud cylinder 2, a machine head 1 is installed, and the passage between the machine head 1 and the mud cylinder 2 is The compressor neck 3 is connected. Such as figure 2 As shown, the present invention adds a section of transition machine neck 4 between the upstream of compressor neck 3, that is, between mud cylinder 2, so that the overall structure of the machine neck is two-stage.

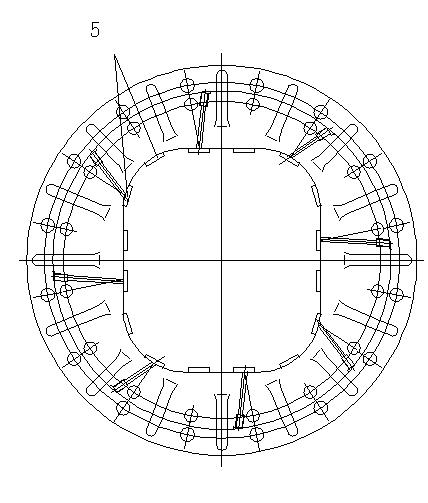

[0025] Such as image 3 , 4 As shown in , the transition machine neck 4 is the same as the compressor neck 3, and also has a conical structure, and its outer periphery and inner hole structure are transition sections between the mud cylinder 2 and the compressor neck 3. And on its inner wall, there are several guiding mechanisms, which can be image 3 , 4 As shown in , the ribs 5 penetrate through the transition neck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com