Batch-type label printing machine with laminating device

A laminating device, intermittent technology, applied in printing presses, rotary printing presses, general parts of printing machinery, etc., can solve the problems of inability to adjust the indentation position, affecting the quality of label products, long extrusion time, etc. Simple, easy to operate, and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

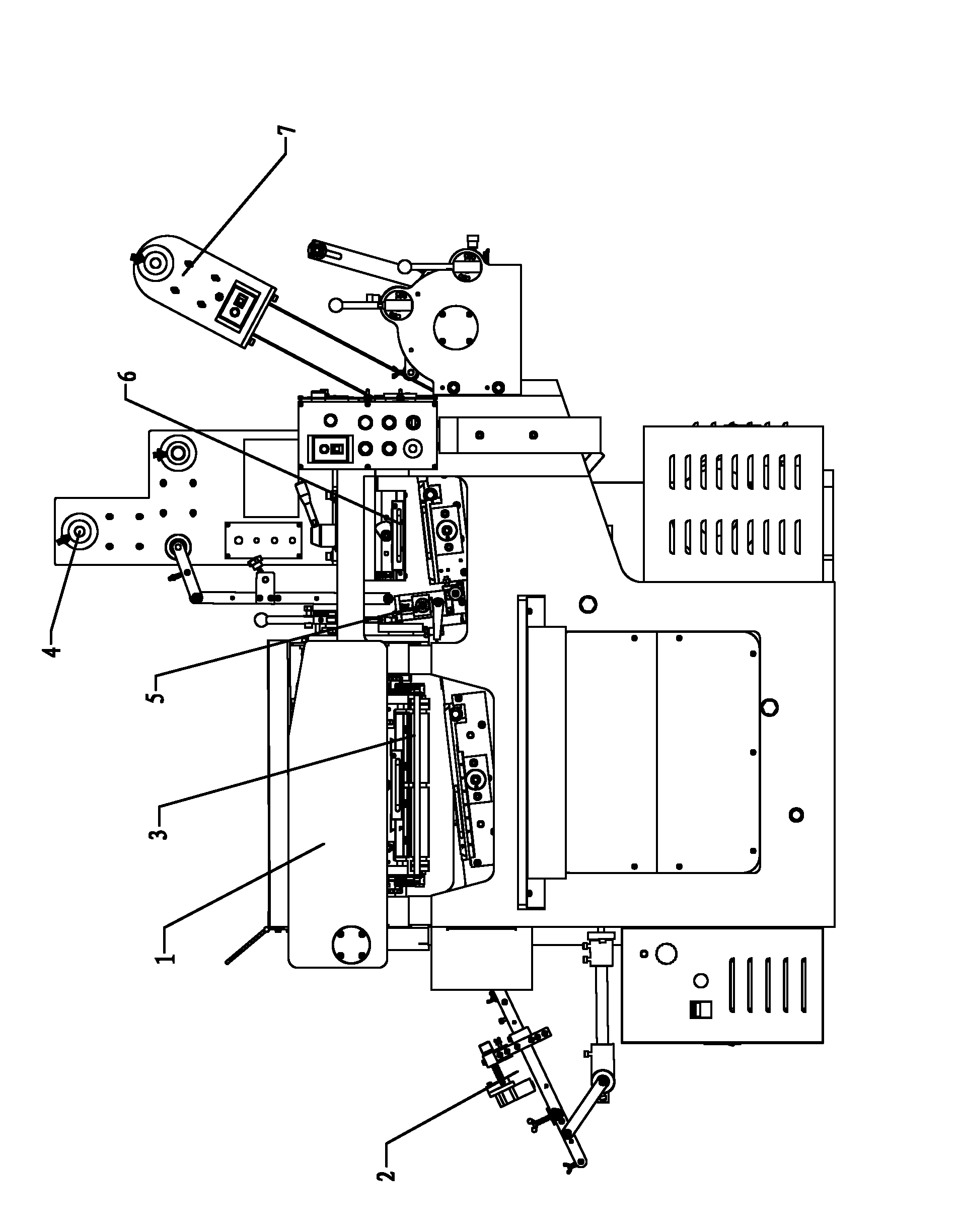

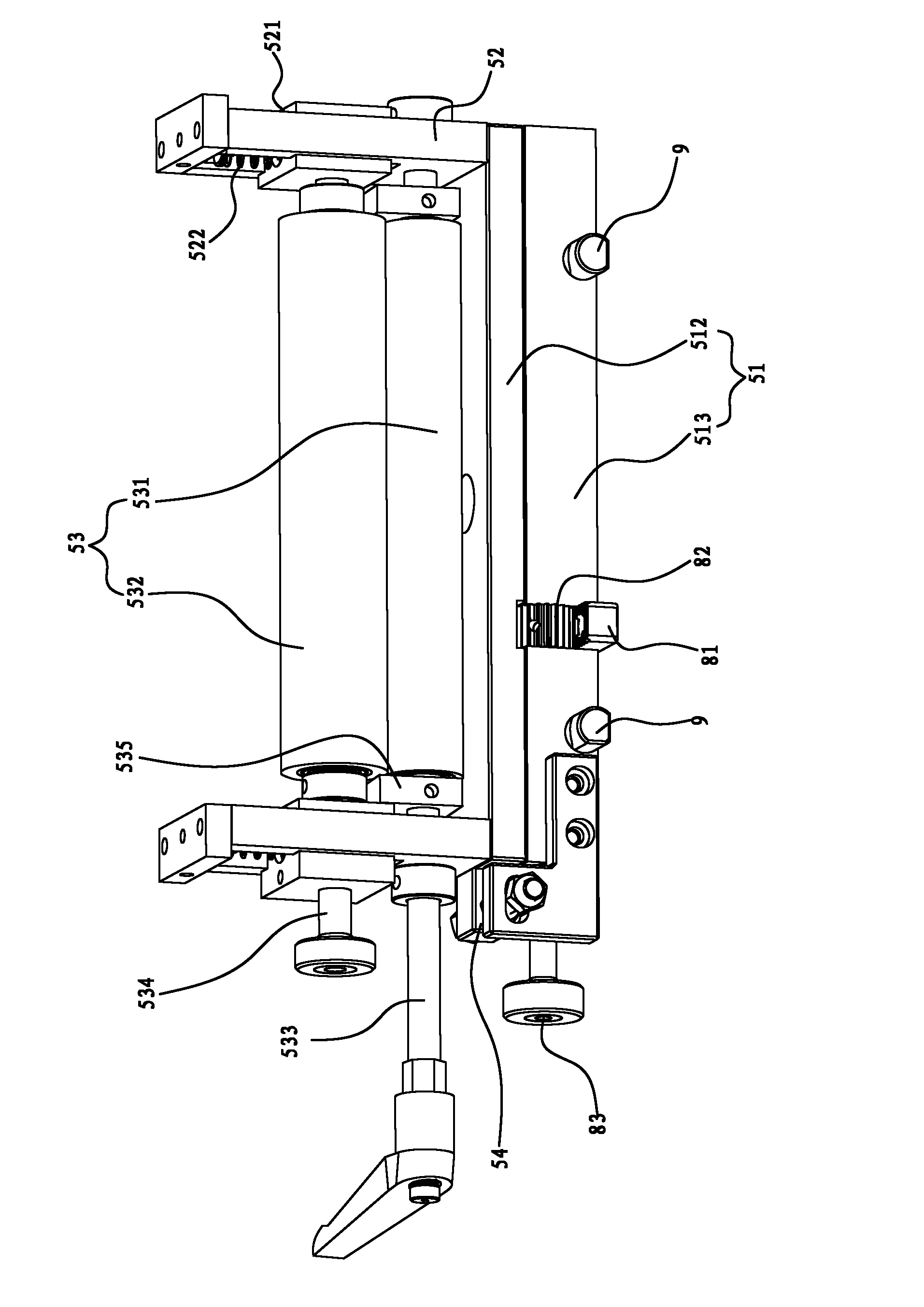

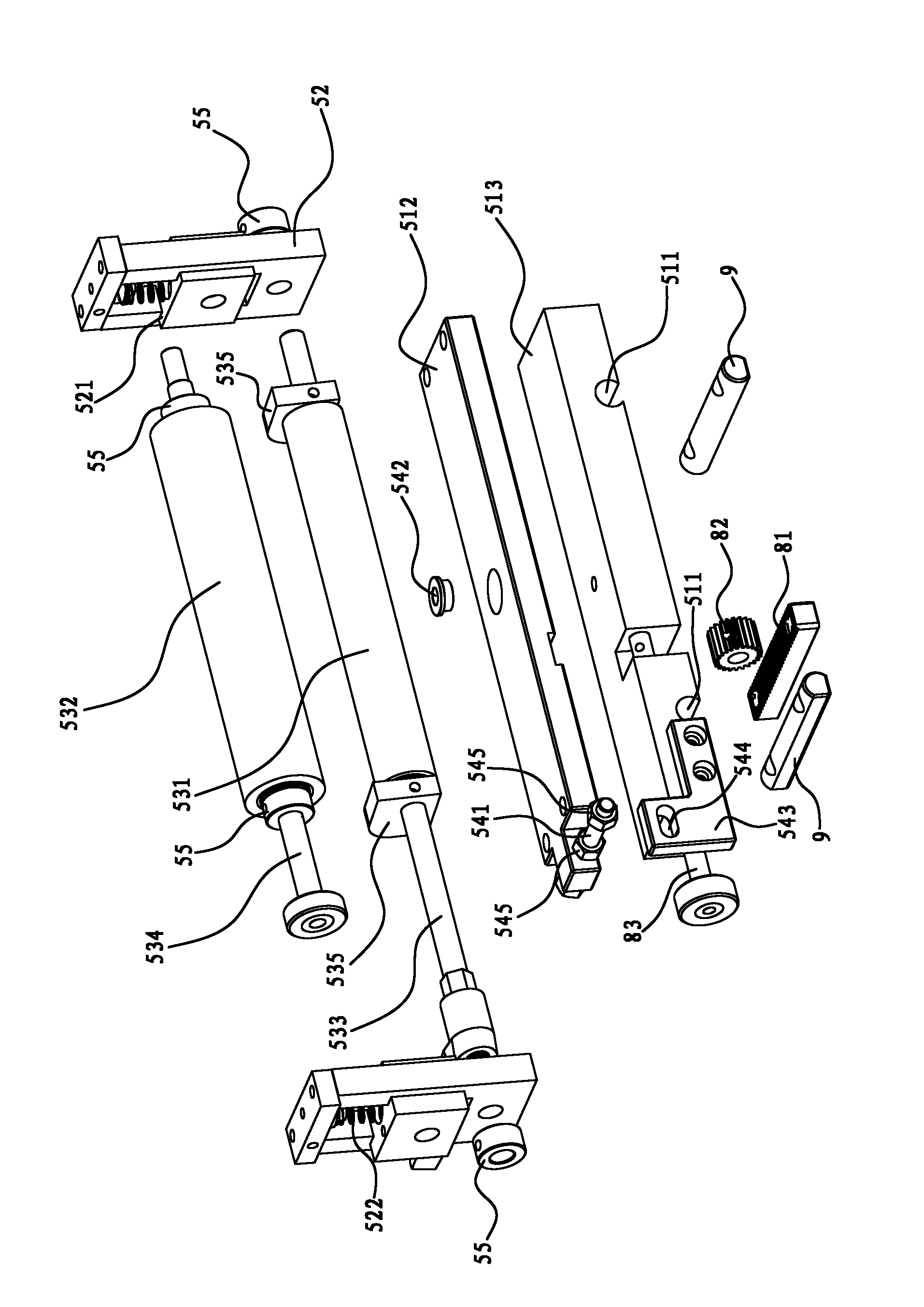

[0026] Below in conjunction with accompanying drawing, the present invention will be further described, see figure 1 , figure 2 , image 3 with Figure 4 As shown, this is a preferred embodiment of the present invention.

[0027] An intermittent label printing machine with a laminating device, comprising a frame 1, the frame 1 is sequentially provided with a raw material unwinding device 2, a printing device 3, a laminating device, a die-cutting device 6 and a winding device 7, Described laminating device comprises film material unwinding roller group 4 and laminating roller group 5, and described laminating roller group 5 comprises base 51, roll stand 52 and laminating roller wheel pair 53, and described roll stand 52 is fixed on The base 51, the film-coating roller pair 53 is pivotally arranged on the roll frame 52, a position adjustment device is arranged between the base 51 and the frame 1, and the base 51 passes through the position adjustment device along the The fe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap