Recording apparatus and recording method

A technology of recording equipment and recording head, applied in printing and other directions, can solve problems such as disordered discharge direction, impossibility of ink discharge, bad ink discharge, etc., and achieve the effect of suppressing absorption and suppressing bad discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

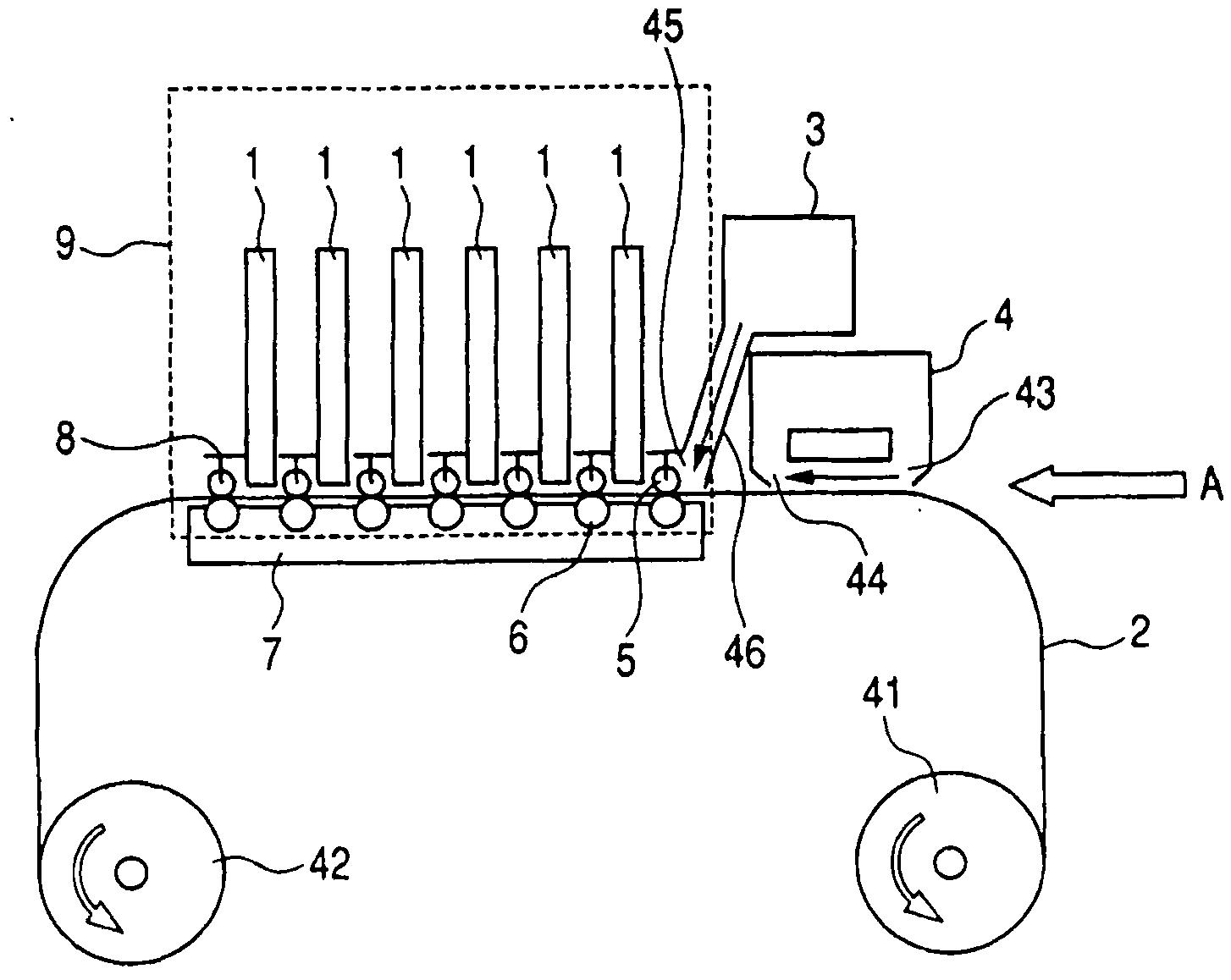

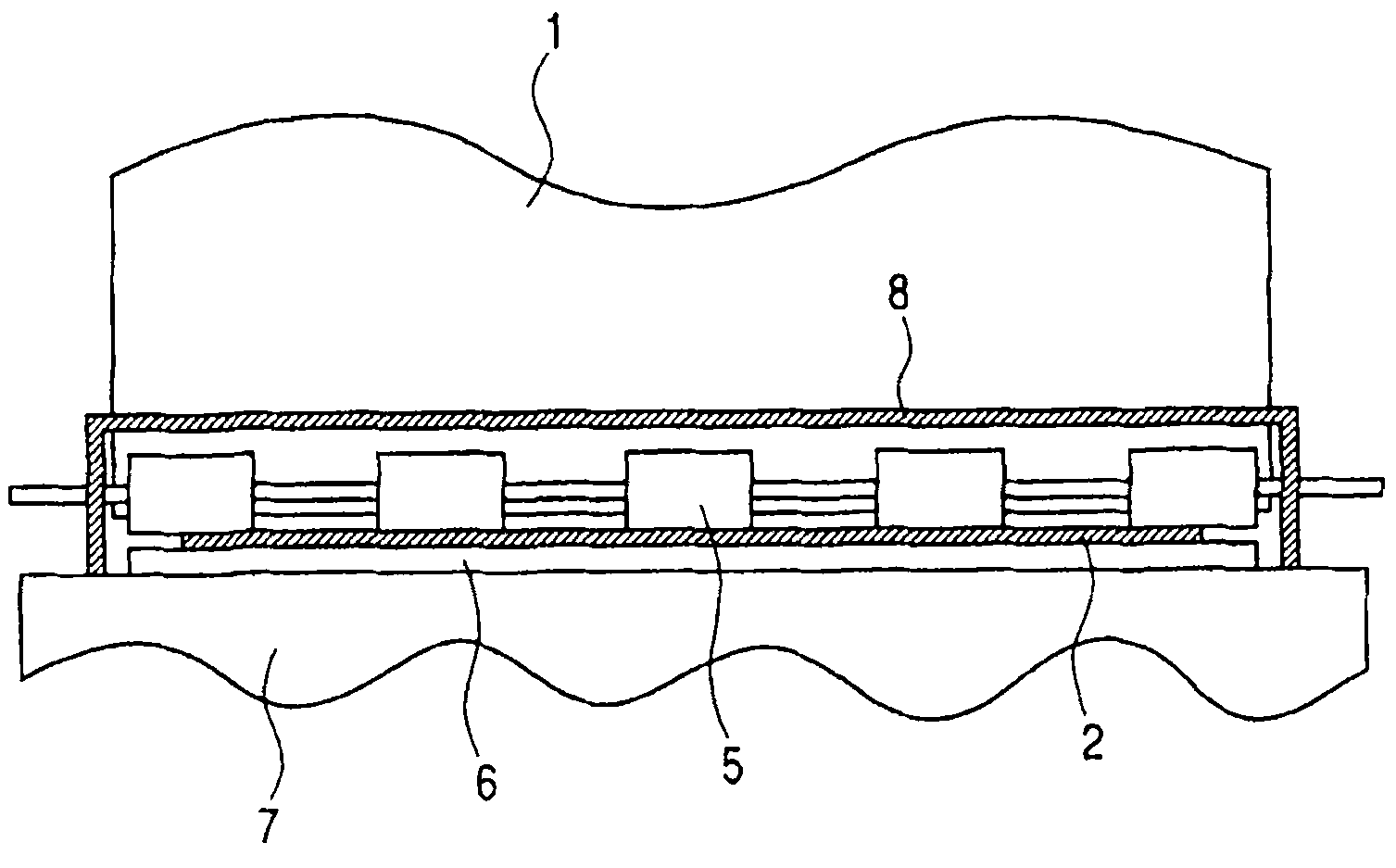

[0049] Assume that the recording head 1 is a six-color recording head 1 of black, cyan, photo-cyan, magenta, photo-magenta, and yellow, which has a recording width of 15.24 cm (6 inches). A glossy roll paper for inkjet recording with a width of 12.70 cm (5 inches) was set as Sheet 2, and continuous image recording with an image size of 12.70 cm×17.78 cm (5×7 inches) was performed. At this time, the ambient temperature around the inkjet recording apparatus was 25 degrees Celsius, and the relative humidity was 55%. When the moisture content of the roll paper as sheet 2 was measured using an electronic hygrometer (main body: MR-200, probe: KG-PA) manufactured by Sanko Electronic Laboratory Co., Ltd. When measured, the moisture content was about 6%. After renewing the ink in the nozzles by performing "waste discharge" of the recording head 1 inside the caps before recording an image, the caps are emptied and the recording heads 1 are moved to the image recording position.

[005...

example 2

[0055]In Example 2, recording was performed on the sheet 2 in the same manner as in Example 1, except that the gas at a temperature of 40 degrees Celsius and a relative humidity of 60% (30.6 g / m3 in absolute humidity) was used as the gas supplied by the first supply unit. 4 humidified said gas. In addition, the amount of moisture supplied to the roll paper at this time was about 0.24 g / sec. When the moisture content of the roll paper humidified by the first supply unit 4 was measured, the moisture content was about 15%.

[0056] Furthermore, in a state where the humidified gas from the first supply unit 4 and the second supply unit 3 is supplied, the temperature and relative humidity near the tip of the recording head 1 are measured. As a result, in the recording head 1 on the most upstream side, the temperature was 30 degrees Celsius and the relative humidity was 95%, and in the recording head 1 on the most downstream side, the temperature was 30 degrees Celsius and the rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com