Nonmagnetic texture NiV (nickel vanadium) alloy base band and smelting preparation method thereof

A non-magnetic and alloy technology, applied in the field of non-magnetic textured NiV alloy base strips for coated conductors and its preparation, can solve the problems of decreased stacking fault energy of alloys, unsatisfactory cubic texture content, limited practical application, etc. The effect of cubic texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

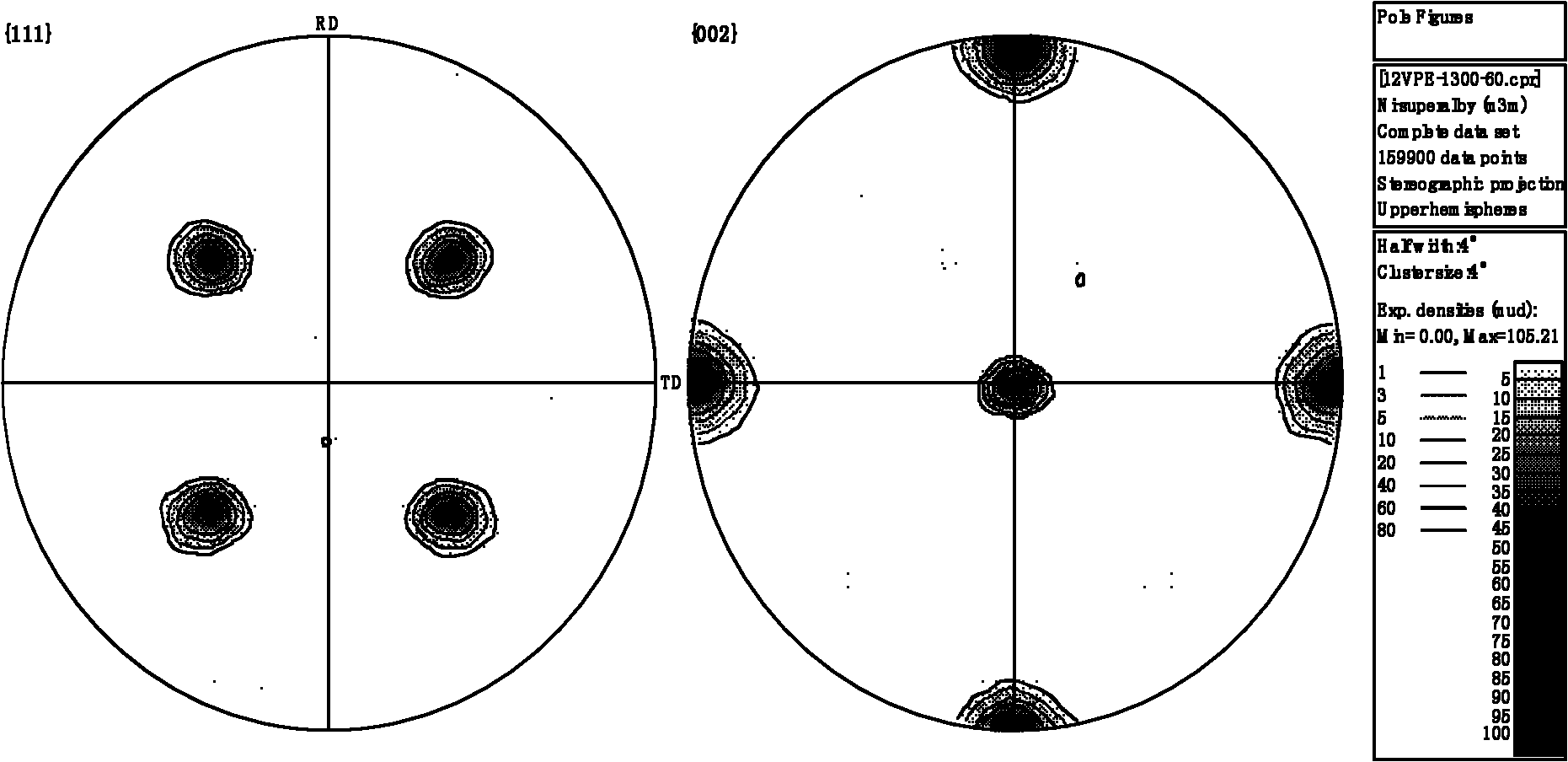

[0021] The Ni block and the V block with a purity of 99.9% are smelted at 1600°C for 10 minutes under vacuum conditions to form a NiV alloy solid solution according to the proportion of V at 12%, and then cast and forged to obtain the NiV alloy. Initial ingot casting; the initial ingot is hot-rolled to obtain the initial ingot; the initial ingot is cold-rolled, and the pass deformation is 5%, and finally a cold-rolled base strip with a total deformation of 98% and a thickness of 80 μm is obtained; Rolled base strip in Ar4%H 2 Anneal at 550° C. for 30 minutes under a protective atmosphere of mixed gas, and then raise the temperature to 1100° C. and anneal for 60 minutes to obtain the final alloy base strip. The (111) and (002) surface pole figures of the alloy baseband are as follows figure 1 shown by figure 1 It can be seen that the alloy substrate has a strong cubic texture.

Embodiment 2

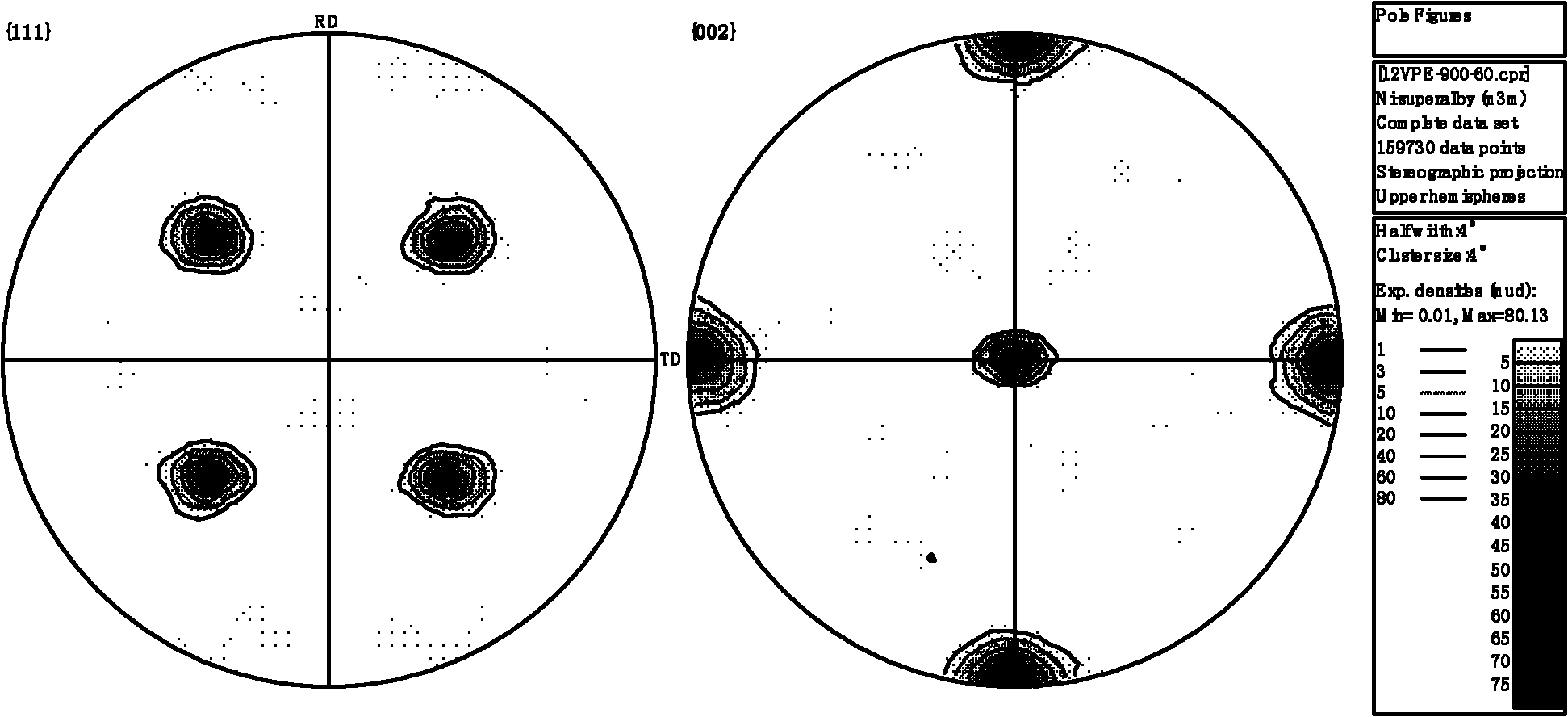

[0023] The Ni block and the V block with a purity of 99.99% are smelted at 1600°C for 10 minutes under vacuum conditions to form a NiV alloy solid solution according to the proportion of V at 11%, and then cast and forged to obtain the NiV alloy. Initial ingot casting; the initial ingot is hot-rolled to obtain the initial ingot; the initial ingot is cold-rolled, the pass deformation is 10%, and the final cold-rolled base strip with a total deformation of 95% and a thickness of 60 μm is obtained; Rolled base strip in Ar4%H 2 Anneal at 550° C. for 30 minutes under a protective atmosphere of mixed gas, and then raise the temperature to 900° C. and anneal for 90 minutes to obtain the final alloy base strip. The (111) and (002) surface pole figures of the alloy baseband are as follows figure 2 shown by figure 2 It can be seen that the alloy substrate has a strong cubic texture.

Embodiment 3

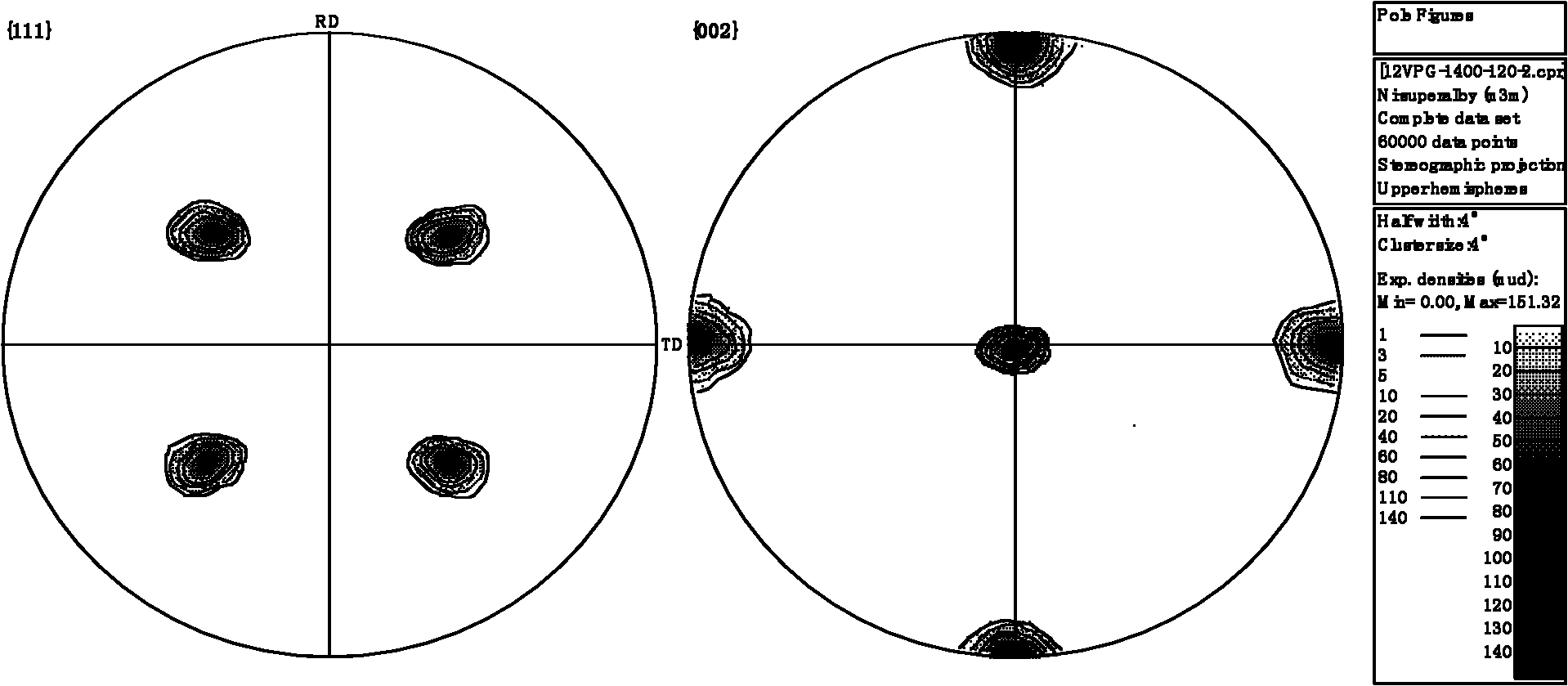

[0025] The Ni block and the V block with a purity of 99.9% are smelted at 1600°C for 10 minutes under vacuum conditions to form a NiV alloy solid solution according to the proportion of V at 9%, and then cast and forged to obtain the NiV alloy. Initial ingot casting; the initial ingot is hot-rolled to obtain the initial ingot; the initial ingot is cold-rolled, and the pass deformation is 15%, and finally a cold-rolled base strip with a total deformation of 95% and a thickness of 120 μm is obtained; Rolled base strip in Ar4%H 2 Anneal at 550° C. for 30 minutes under a protective atmosphere of mixed gas, and then raise the temperature to 1050° C. and anneal for 30 minutes to obtain the final alloy base strip. The (111) and (002) surface pole figures of the alloy baseband are as follows image 3 shown by image 3 It can be seen that the alloy substrate has a strong cubic texture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com