Preparation method of non-magnetic texture NiV alloy baseband

A non-magnetic, alloy-based technology, applied in the usage of superconductor elements, cable/conductor manufacturing, electrical components, etc., can solve the problems of alloy stacking fault energy reduction, difficult to obtain high cubic texture content, etc., to achieve good cubic texture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

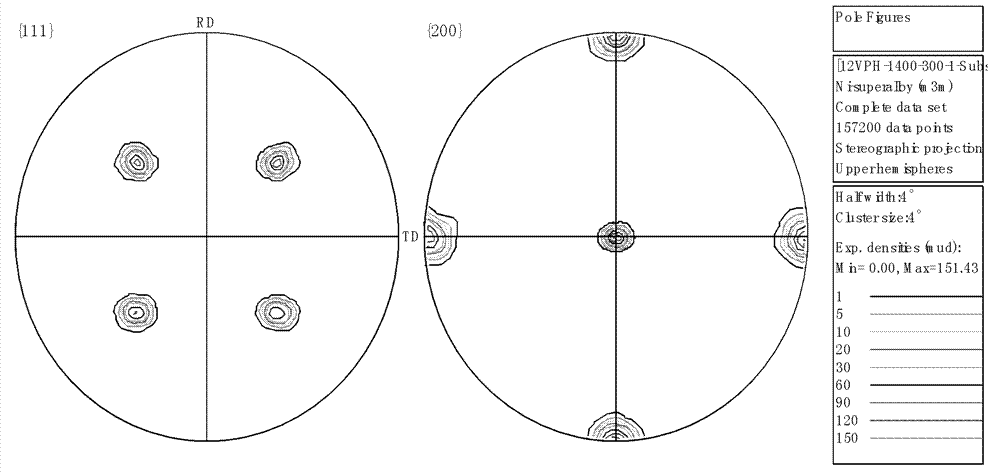

Embodiment 1

[0027] Ni powder and V powder with a purity of 99.9% are Ni 88 V 12 Weigh and mix the powder according to the ratio, and then use a ball mill for ball milling. The ball mill speed is 300rpm, and the total time of ball milling is 10h. After being fully mixed, put the mixed powder into the mold; then put the mold filled with powder Put it into the spark plasma sintering equipment, pressurize and sinter under vacuum conditions, wherein the sintering pressure is 50Mpa, the sintering temperature is 850°C, and the time is 10min to obtain a compact, and then the pressed compact is placed in Ar4%H 2 The homogenization treatment was carried out under the protection condition of mixed gas at 1400°C, and the sintering time was 20 hours to obtain the initial billet; the initial billet was cold-rolled, the deformation amount of each pass was 5%, the total deformation amount was 99%, and the final thickness was 80 μm. Cold-rolled base strip; cold-rolled base strip in Ar4%H 2 Anneal at 550...

Embodiment 2

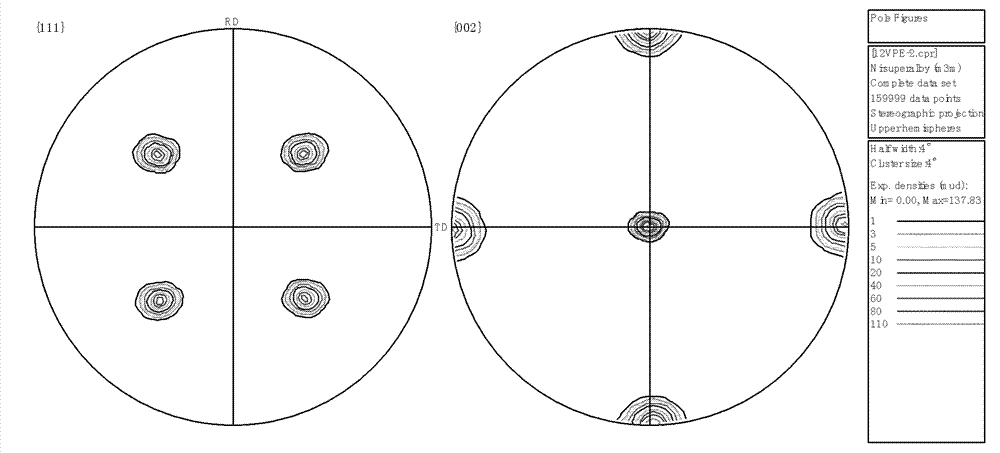

[0029] Ni powder and V powder with a purity of 99.99% are Ni 90.5 V 9.5 Weigh and mix the powder according to the ratio, and then use a ball mill for ball milling. The ball mill speed is 150rpm, and the total time of ball milling is 15h. After being fully mixed, put the mixed powder into the mold; then put the mold filled with powder Put it into the spark plasma sintering equipment, pressurize and sinter under vacuum conditions, wherein the sintering pressure is 30Mpa, the sintering temperature is 1000°C, and the time is 5min to obtain compacts, and then the pressed compacts are sintered under vacuum conditions at 1200°C Carry out homogenization treatment, the sintering time is 22h, obtain initial billet; Carry out cold rolling to initial billet, pass deformation amount is 10%, total deformation amount is 95%, finally obtain the cold-rolled base strip alloy base strip with the thickness of 90 μm; Rolled base strip in Ar4%H 2 Anneal at 550° C. for 30 minutes under a protectiv...

Embodiment 3

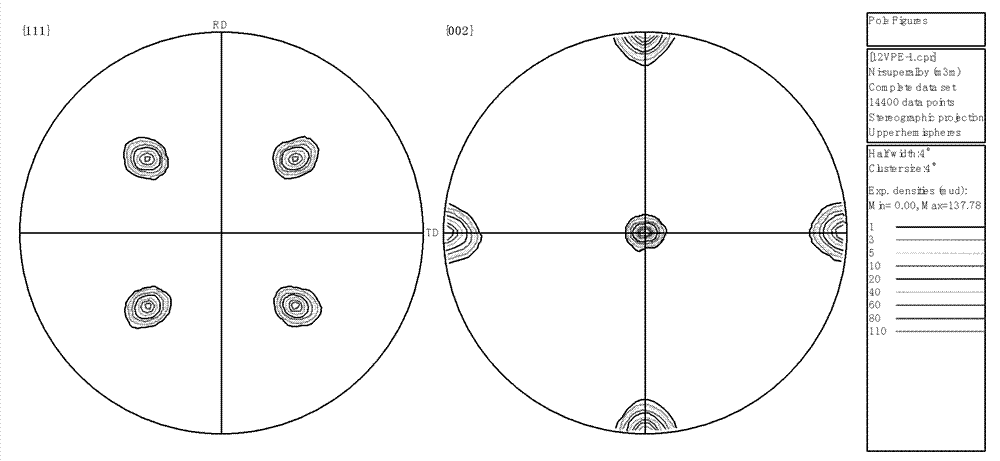

[0031] Ni powder and V powder with a purity of 99.9% are Ni 91 V 9 Weigh and mix the powder according to the ratio, and then use a ball mill for ball milling. The ball mill speed is 250rpm, and the total time of ball milling is 12h. After being fully mixed, put the mixed powder into the mold; then put the mold filled with powder Put it into the spark plasma sintering equipment, pressurize and sinter under vacuum conditions, wherein, the sintering pressure is 50Mpa, the sintering temperature is 900°C, and the time is 10min to obtain a compact, and then the pressed compact is placed in Ar4%H 2 The homogenization treatment was carried out at 1000°C under the protection of mixed gas, and the sintering time was 25 hours to obtain the initial billet; the initial billet was cold-rolled, the deformation amount of each pass was 5%, the total deformation amount was 95%, and the final thickness was 60 μm. Cold-rolled base strip; cold-rolled base strip in Ar4%H 2 Anneal at 550° C. for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com