Cu-base alloy baseband for coated conductor and preparation method thereof

A technology of coated conductors and base alloys, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problem of the reduction of cubic texture content, the base band is easily oxidized, and the impact on the epitaxial growth of subsequent transition layers and superconducting layers and other issues, to achieve the effect of good oxidation resistance, improved mechanical properties, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

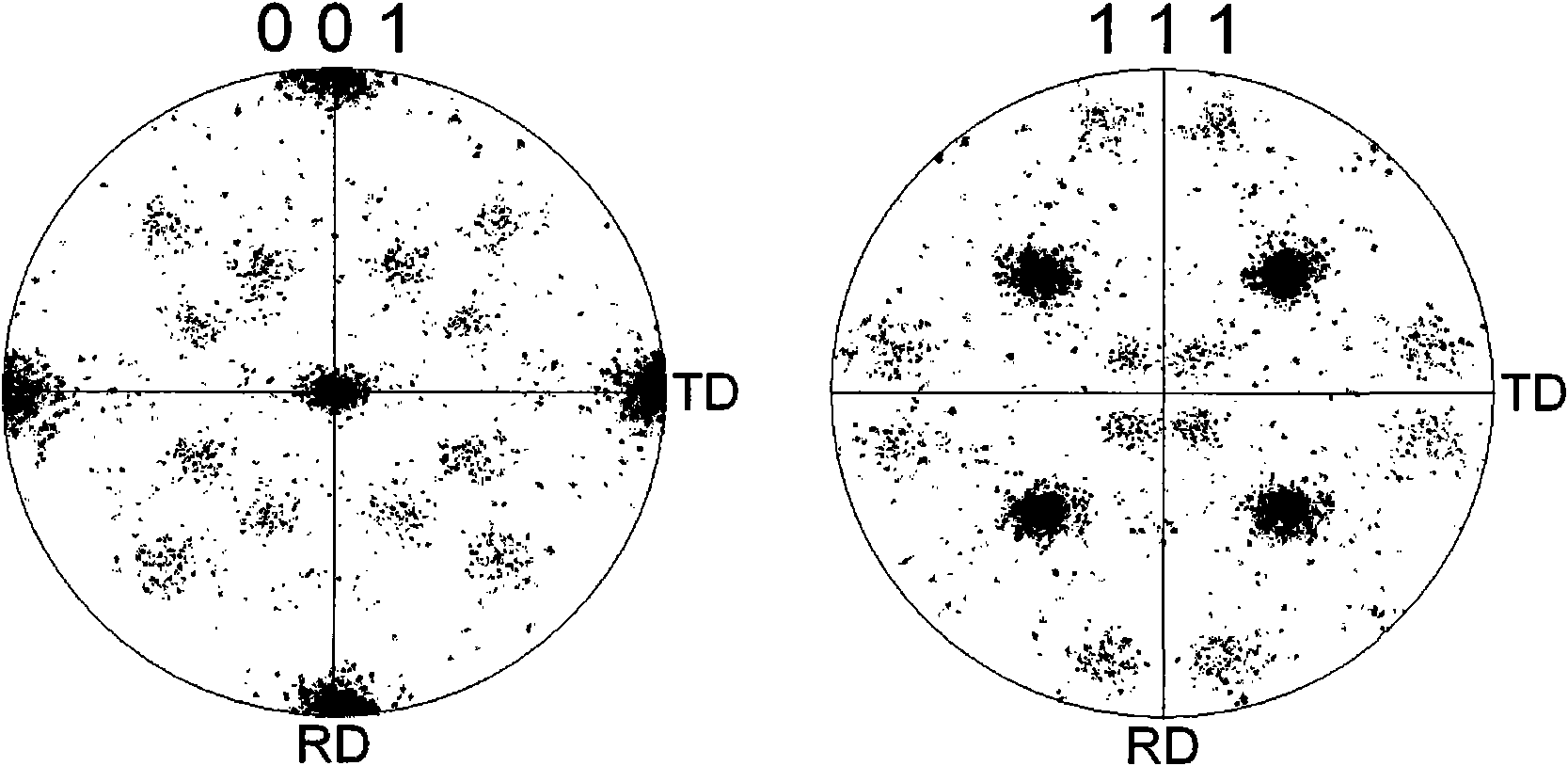

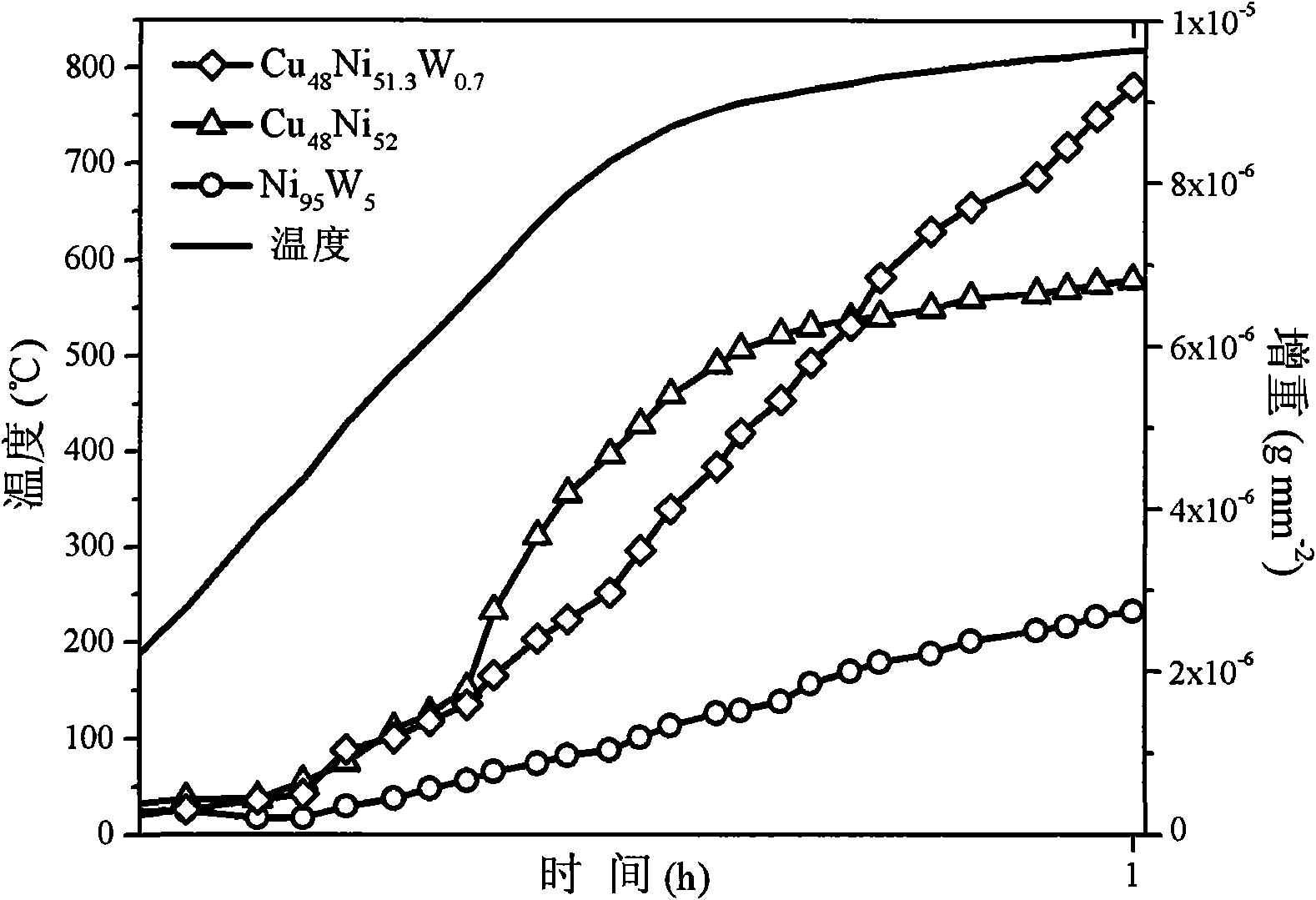

[0025] The high-purity Cu powder, Ni powder and W powder are Cu 48 Ni 51.3 W 0.7 Weigh and mix the powder according to the ratio, and then use a high-energy ball mill for ball milling. After being fully mixed, put the mixed powder into the mold; then the above-mentioned powder that has been placed in the mold is pressed by traditional powder metallurgy cold isostatic pressing Forming, wherein the pressure is 250MPa, holding pressure for 5min; 2 Under the protection of mixed gas or under vacuum conditions, homogenization treatment is carried out at 1000°C, and the sintering time is 10 hours to obtain the initial billet; the initial billet is cold-rolled, and the deformation of each pass is 5-15%. When the deformation is greater than 80%, in Ar / H 2 Mixed gas protection or intermediate heat treatment at 500°C under vacuum conditions, the heat treatment time is 1h; continue rolling the deformed base strip that has been heat-treated, and finally obtain a cold-rolled base strip w...

Embodiment 2

[0027] Cu powder, Ni powder and W powder are Cu powder by atomic percentage 50 Ni 48.5 W 1.5 Weigh and mix the powder according to the ratio, and then grind it with a high-energy ball mill. After it is fully mixed, put the mixed powder into the mold; Forming, wherein the pressure is 250MPa, holding pressure for 5min; 2 Under the protection of mixed gas or under vacuum conditions, the homogenization treatment is carried out at 1100°C, and the sintering time is 15 hours to obtain the initial billet; the initial billet is cold-rolled, the deformation of each pass is 5-15%, and the total deformation is greater than 95%. Get the cold-rolled base strip that thickness is 80um; The cold-rolled base strip is in Ar / H 2 Anneal at 200° C. for 30 minutes under a protective atmosphere of mixed gas, and then raise the temperature to 900° C. and anneal for 120 minutes to obtain the final alloy base strip.

Embodiment 3

[0029] Cu powder, Ni powder and W powder are Cu powder by atomic percentage 60 Ni 37 W 3 The proportion of powder is weighed and mixed, and then ground by a high-energy ball mill. After being fully mixed, the mixed powder is put into a mold; Sintering under pressure, wherein the sintering pressure is 50Mpa, the sintering temperature is 800°C, and the time is 5min to obtain a compact, and then the compacted compact is placed in Ar / H 2 Homogenization treatment is carried out under the protection of mixed gas or vacuum at 1000°C, and the sintering time is 1h to obtain the initial billet; the initial billet is cold-rolled, with a deformation of 5-15% in each pass and a total deformation of more than 95%. Get the cold-rolled base strip that thickness is 90um; The cold-rolled base strip is in Ar / H 2 Anneal at 300° C. for 30 minutes under a protective atmosphere of mixed gas, and then raise the temperature to 900° C. and anneal for 120 minutes to obtain the final alloy base strip....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com