Steel box structure of combined bridge deck

A combined bridge and panel technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as fatigue performance, thermal stability, difficult construction, high unit price of pavement materials, and difficulty in anti-corrosion coating inside the box, etc., to achieve Strong durability, easy processing, and easier corrosion protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

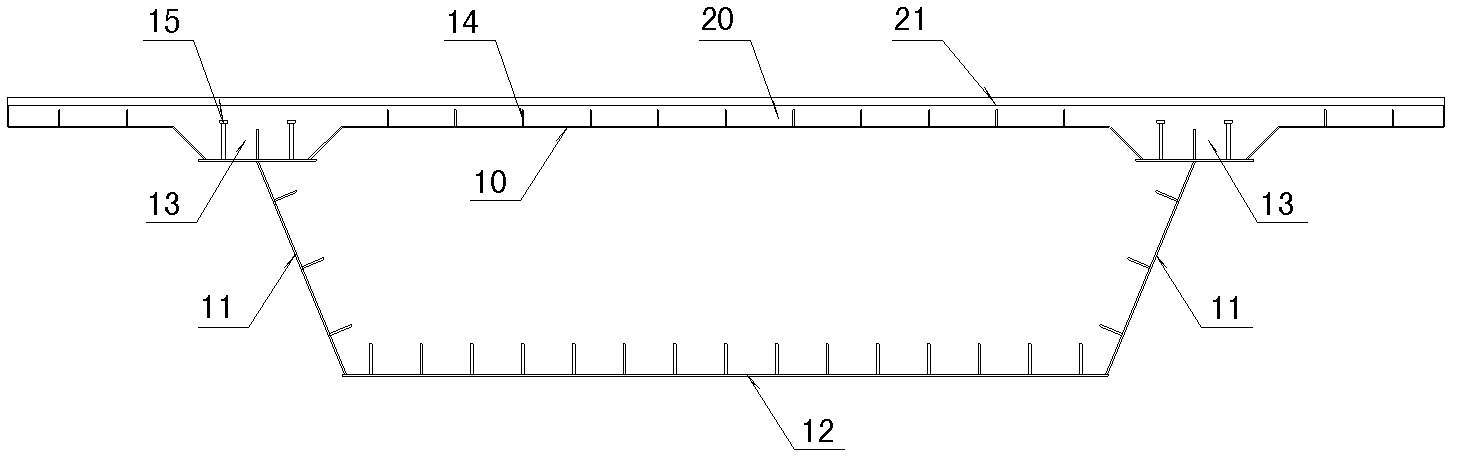

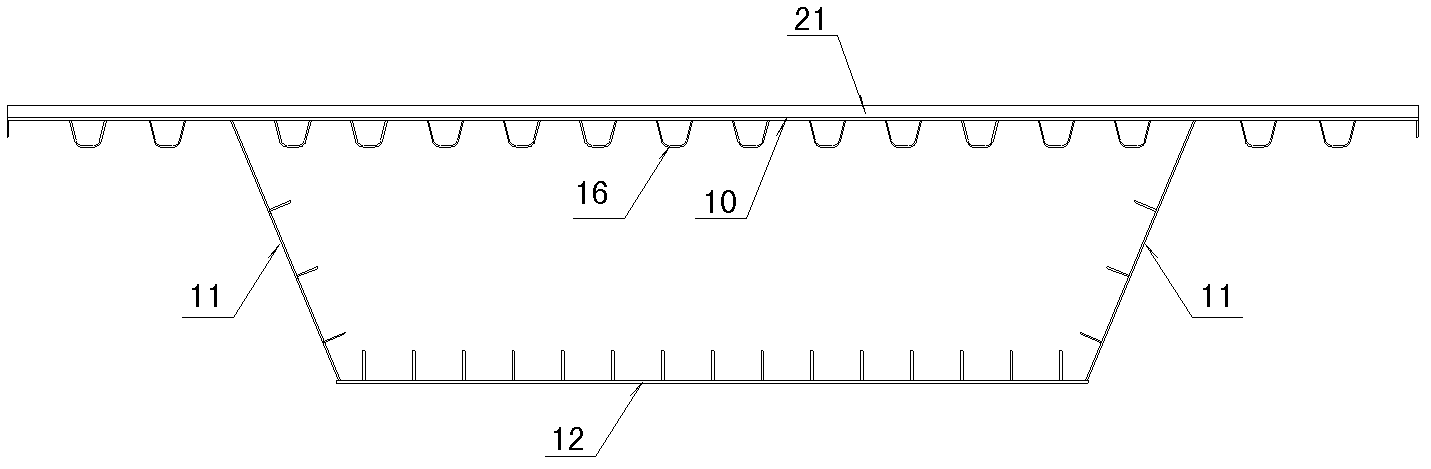

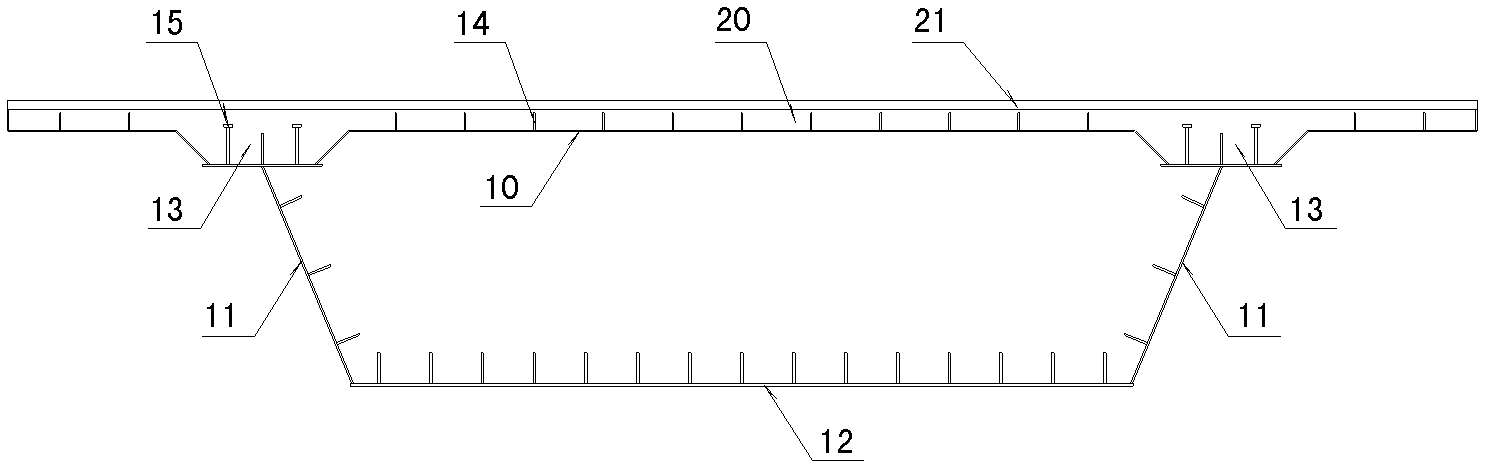

[0012] refer to figure 1 , the composite bridge deck steel box structure of the present invention, the steel box girder is constituted by the bridge deck steel bottom plate 10, two side webs 11 and the bottom plate 12, the bridge deck steel bottom plate 10 is fixedly connected with the two side webs 11, and the diaphragm. The upper surface of the bridge deck steel bottom plate 10 is fixed with vertical shear plates 14 at intervals along the bridge direction or across the bridge direction, and a reinforced concrete layer 20 is poured on the bridge deck steel bottom plate 10 . The shear plate 14 doubles as a longitudinal plate rib or a transverse plate rib.

[0013] The invention effectively solves the technical problems of fatigue performance, thermal stability and combination of paving layer and steel bridge deck in the existing steel box structure bri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com