Underground drainage pipeline leakage detection method and device

A technology for underground drainage and detection methods, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

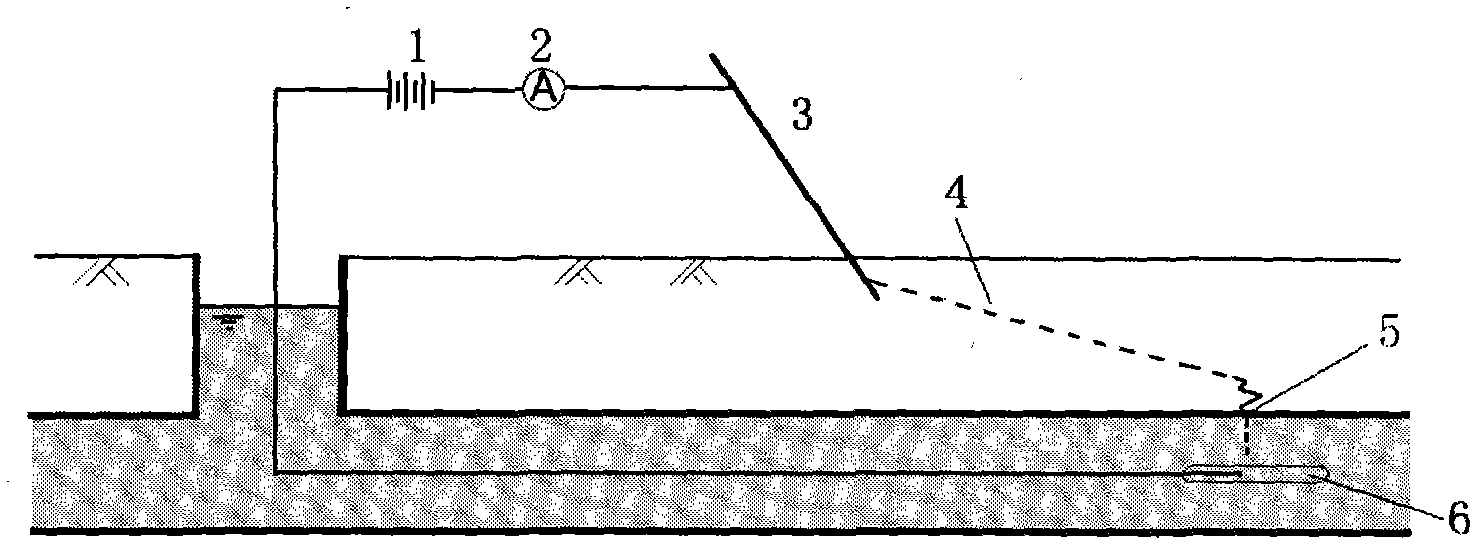

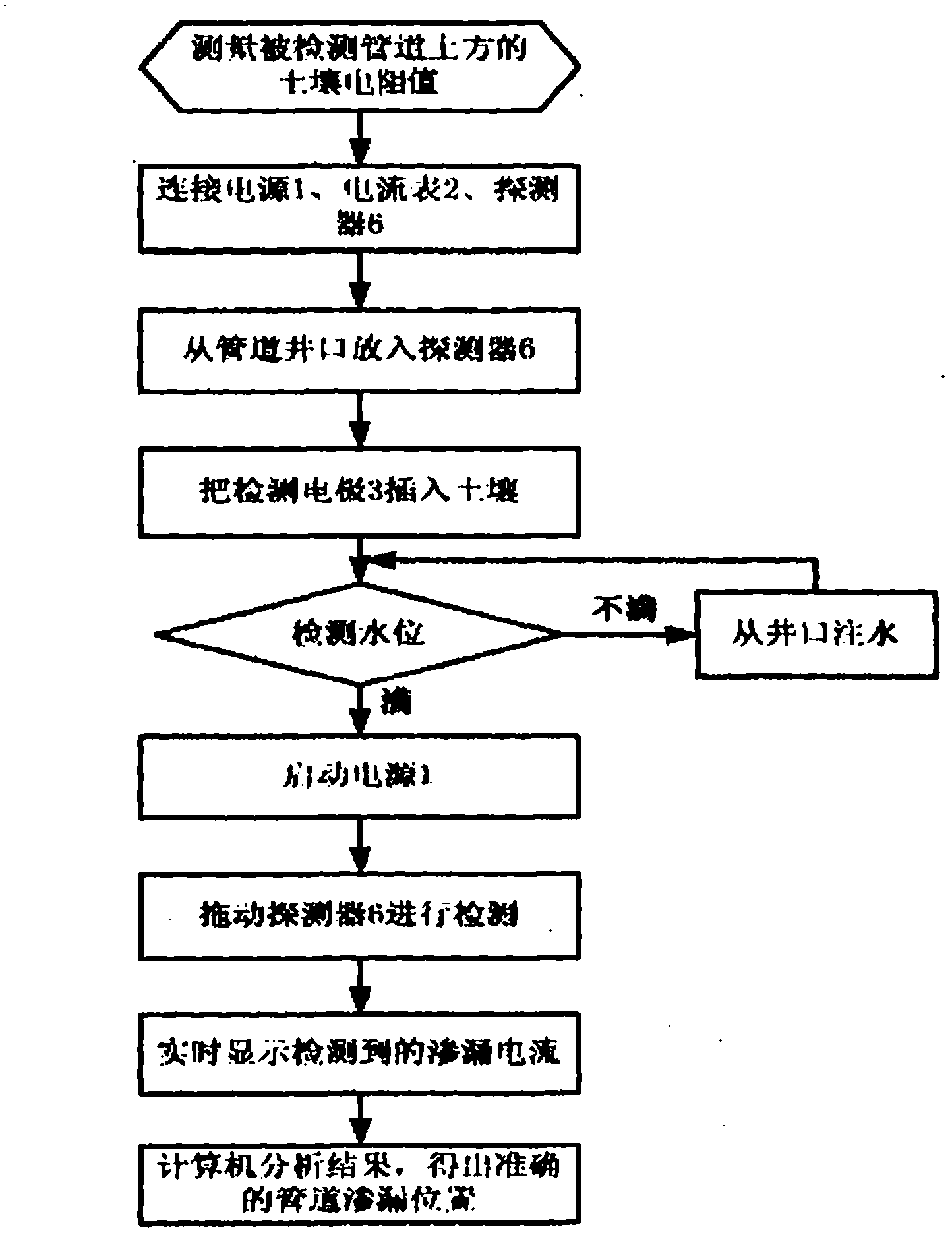

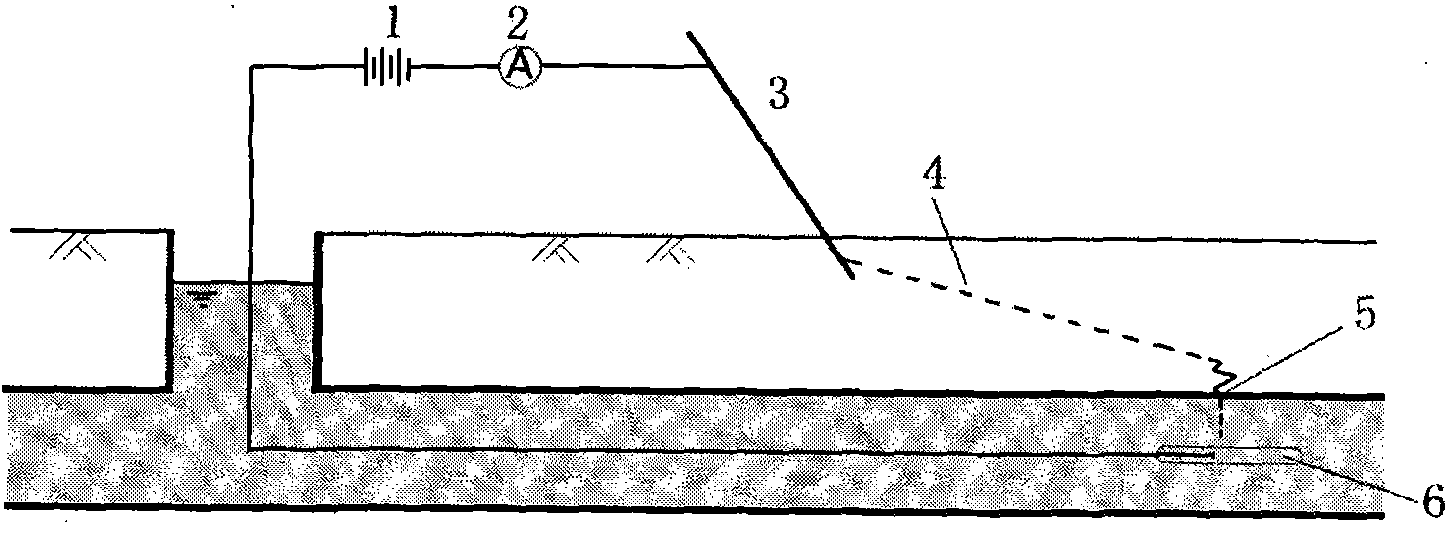

[0034] Such as figure 1 As shown, one end of the power supply 1 is connected to the high-sensitivity ammeter 2, and the other end is connected to the detector 6. The detector 6 is attached with a pressure sensor, and the ammeter 2 is connected to the detection electrode 3. Before the detector is inserted into the pipeline, the entire circuit is in an open state. When the detector is inserted into the pipe and the pipe is filled with water, a closed circuit is formed. In this circuit, the soil exhibits low-resistance characteristics, and the water in the pipeline also exhibits low-resistance characteristics. Although the undamaged pipe wall exhibits high-resistance characteristics, it exhibits low-resistance characteristics when there are damaged points. When the detector moves in a pipeline full of water, under normal circumstances, the loop current formed by the detection electrode, detector, soil, and pipe wall is very small. When the detector moves to the damaged point of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com