Method for manufacturing street lamp and LED (light emitting diode) streetlamp for implementing method

A technology for LED street lamps and street lamps, which is applied to lampshades, lighting and heating equipment, components of lighting devices, etc., can solve the problems affecting the effective illumination range and illuminance of street lamps, inconvenient light distribution, and difficult light, etc., to increase light efficiency. Utilization rate, light distribution convenience, and the effect of enhancing illumination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

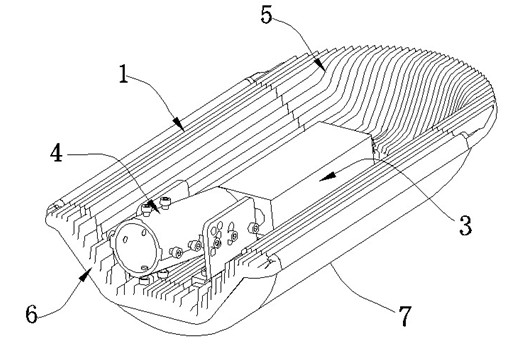

[0057] Example: see Figure 1 to Figure 7 , the embodiment of the present invention provides a street lamp preparation method, which includes the following steps:

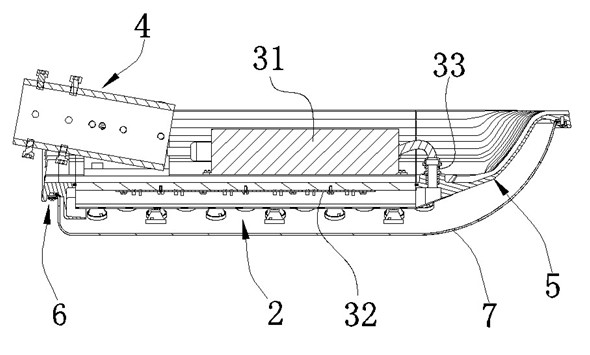

[0058] (1) Prepare the aluminum profile, extrude it and process it into a base 1 with an arc-shaped cross section. The lower surface of the base 1 is arc-shaped convex to form a light distribution surface; the upper surface is correspondingly arc-shaped and concave into, forming a cooling chamber, the cooling chamber is provided with a number of longitudinal fins;

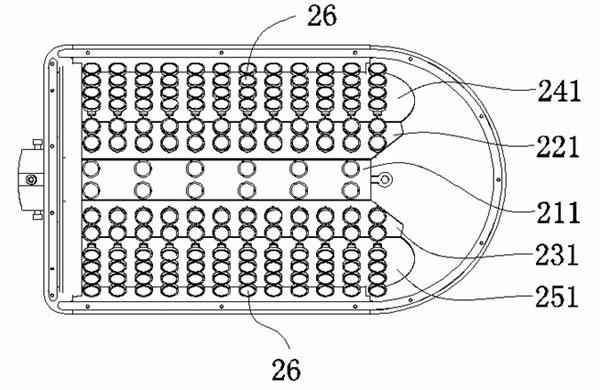

[0059] (2) Prepare a plurality of light-emitting modules 2, arrange these light-emitting modules 2 on the light distribution surface of the base 1 in sequence, and adjust the light intensity of each light-emitting module one by one according to the required light distribution requirements. Irradiation angle to increase the illuminance within the effective irradiation range;

[0060] (3) Installing a driving module 3 capable of driving the light emitti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com