Universal piston temperature measuring device for combustion engine

A technology for temperature measurement and internal combustion engine, which is applied in the direction of measuring device, internal combustion engine test, and electric device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

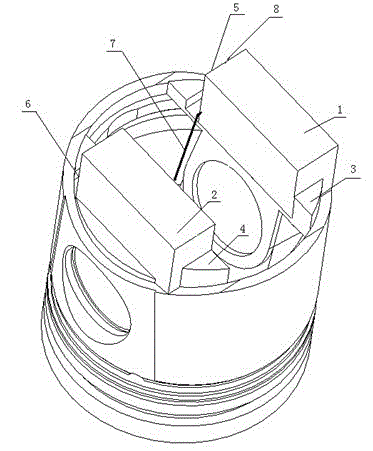

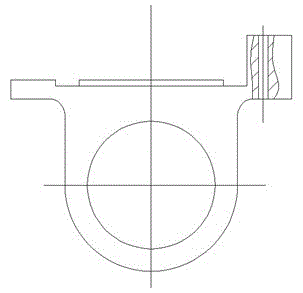

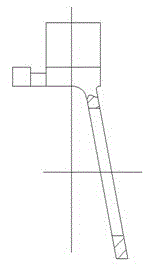

[0030] The side edges a of the first and second insulation boxes 1 and 2 are 0.8mm away from the outer surface of the piston. The shape of the insulation box is a cuboid. The outer wall of the insulation box is made of 0.8mm stainless steel, and the inner wall of the insulation box is made of 2 layers of insulation board and 2-layer mica sheet design; wherein the size of the temperature insulation box 1 is 54mm×22mm×50mm, and the inner cavity of the temperature insulation box 1 is a cuboid, and its size is 43mm× 18mm×37mm; the dimensions of the temperature box 2 are 60mm×22mm×50mm in length×width×height; The distance between each insulation box = 40mm.

[0031] The fixed seat 3,4 lower ends have circular holes, and its size is identical with the piston pin hole; The seat surface has a rectangular plane, and the seat surface size of the fixed seat 3 is 56mm * 21mm, and the seat surface size of the fixed seat 4 is 60mm * 21mm. The fixed seat 3 and the temperature insulation box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com