Profile stretching fixture and horizontal profile stretching testing machine

A fixture and profile technology, applied in the field of profile tensile fixtures and horizontal profile tensile testing machines, can solve problems such as difficult handling, inability to perform breaking tests, and inability to complete detection of mining profiles, to simplify the structure and avoid straightness. Not good, the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

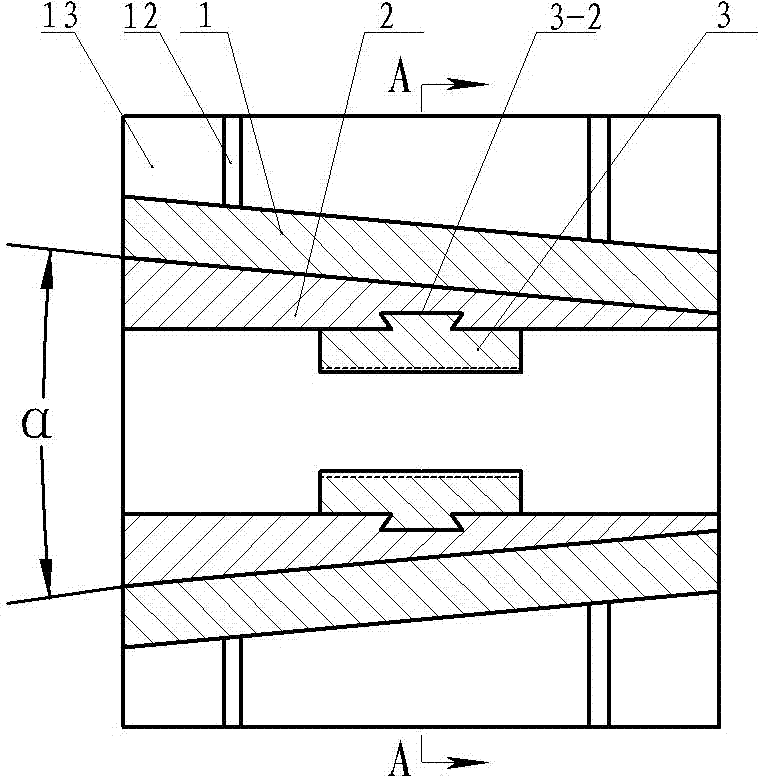

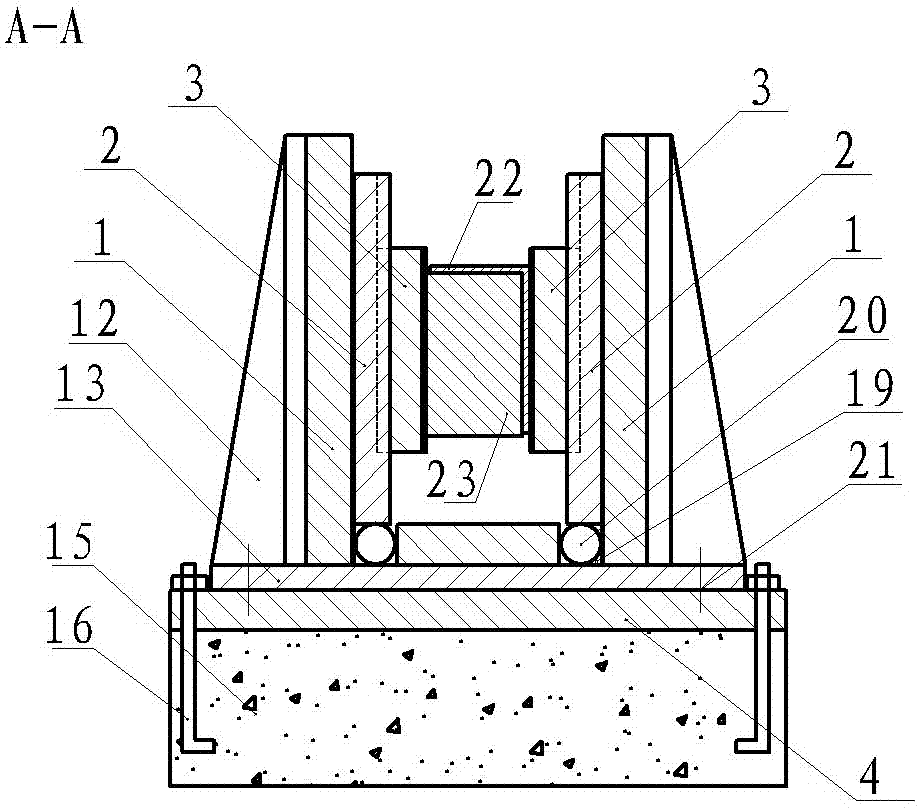

[0038] Embodiment one: see figure 1 , figure 2 , image 3 . A profile stretching fixture, vertically fixing two vertical plates 1 on the bottom plate 13, the outer surfaces of the two vertical plates 1 are not limited but the inner surfaces are inclined and symmetrical, the angle between the inner surfaces of the two vertical plates 1 is inclined is α, and 13°≤α≤23°.

[0039] Two symmetrical wedge-shaped slide plates 2 are respectively matched and attached to the inner surfaces of the two vertical plates 1, so that the angle between the outer surfaces of the two wedge-shaped slide plates 2 is also α, and also satisfies 13°≤α≤23°. The inner surfaces of the two wedge-shaped slide plates 2 are parallel to each other.

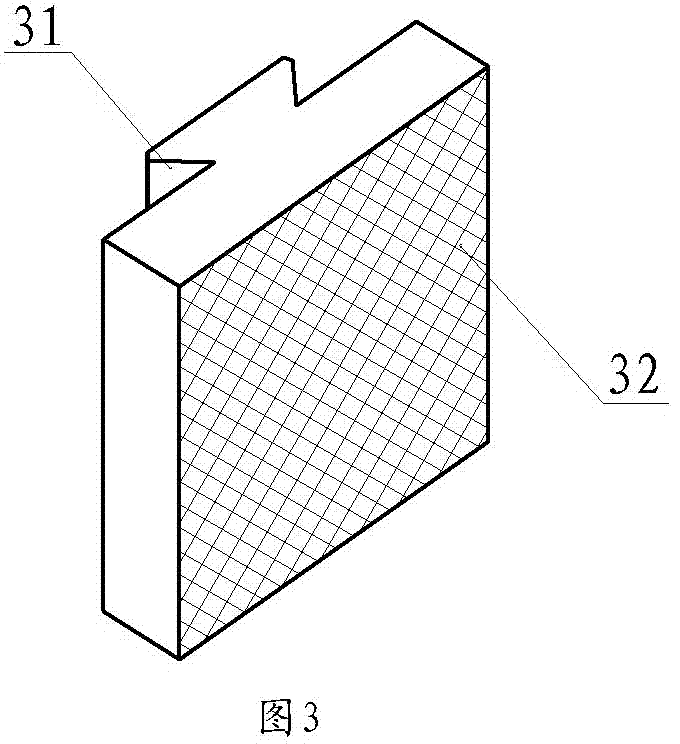

[0040] The inner surface of each wedge-shaped sliding plate 2 and the clamping block 3 are connected together through a vertically arranged dovetail groove and a dovetail strip 31 matching structure.

[0041] The inner surfaces of the two clamping blocks 3 a...

Embodiment 2

[0044] Embodiment two: see figure 1 , image 3 , Figure 4 . The content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the lower part of the wedge-shaped slider 2 is directly in contact with the bottom plate 13 and is in friction fit. For the determination of the center of gravity of the unequal-edge profile, the method of adding a rigid backing plate 33 between the wedge-shaped slider 2 on one side and the vertical plate 1 is used to adjust the coincidence of the center of gravity of the unequal-edge angle steel and the center of the axis.

Embodiment 3

[0045] Embodiment three: see figure 1 , figure 2 , image 3 . A profile stretching jig, the jig is the same as the first embodiment, and will not be repeated, the difference is that the angle between the inner surfaces of the two vertical plates 1 is α, and 15°≤α≤20°. Therefore, the angle between the outer surfaces of the two wedge-shaped slide plates 2 is also α, and 15°≤α≤20°. The range of the friction 31 surface width L is 230 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com