Optical isolator and isolation method

An implementation method and reverse isolation technology, which can be used in instruments, optics, nonlinear optics, etc., can solve the problems of difficulty in making optical isolators, and achieve the effect of increasing the spectral range and simplifying the system structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

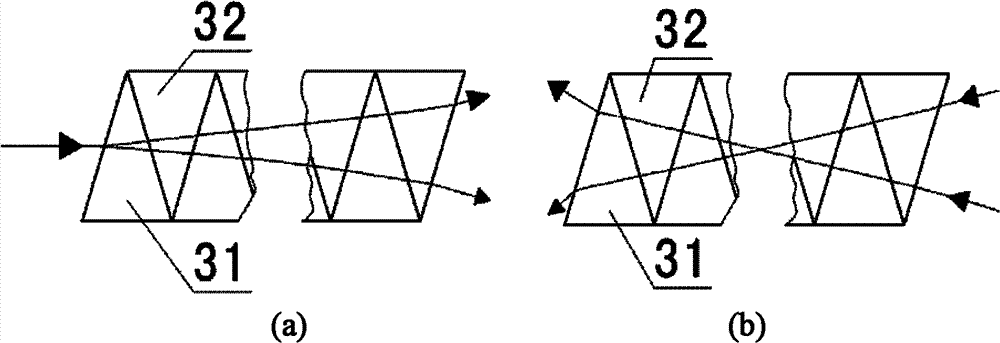

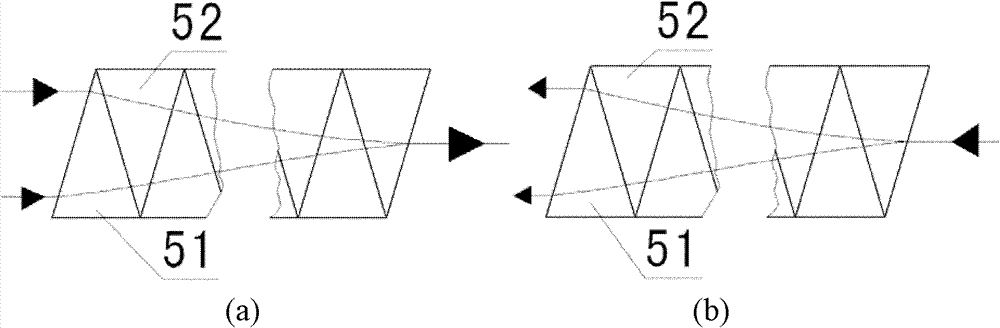

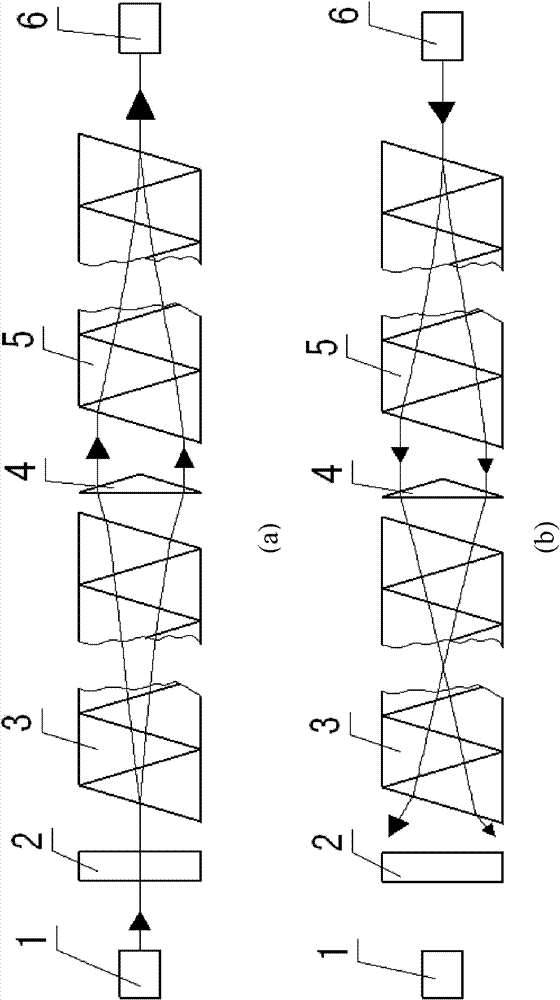

[0032] An optical isolator that allows light to pass unimpeded during forward transmission, but cannot return along the original optical path during reverse transmission, and cannot enter the input end. The isolator uses the non-reciprocal circular birefringence characteristics of magneto-optical glass and a wedge-shaped refractive crystal. The refraction collimation function and the reciprocal circle birefringence characteristic of the natural optical rotation crystal to realize the function of the optical isolator. The task of the present invention is achieved through the following schemes: incident fiber 1, polarizer 2, magneto-optical wedge glass group 3, tapered refractive prism 4, natural-rotation wedge crystal group 5, exit fiber 6, magnetic ring (magnet tube) 9) The optical path device composed of 9 is fixed in the inner packaging tube 10, and they are all on the same optical axis. The inner packaging tube 10 is covered with a sealed metal shell and the outer packaging s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com