Winding core and wafer-processing belt wound on same

A technology of wafer processing and winding cores, which is applied in the fields of electrical components, novolak epoxy resin adhesives, semiconductor/solid-state device manufacturing, etc., can solve the problems of limited support layer width, narrow support layer width, influence, etc., to achieve Effect of reducing winding pressure and suppressing transfer marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

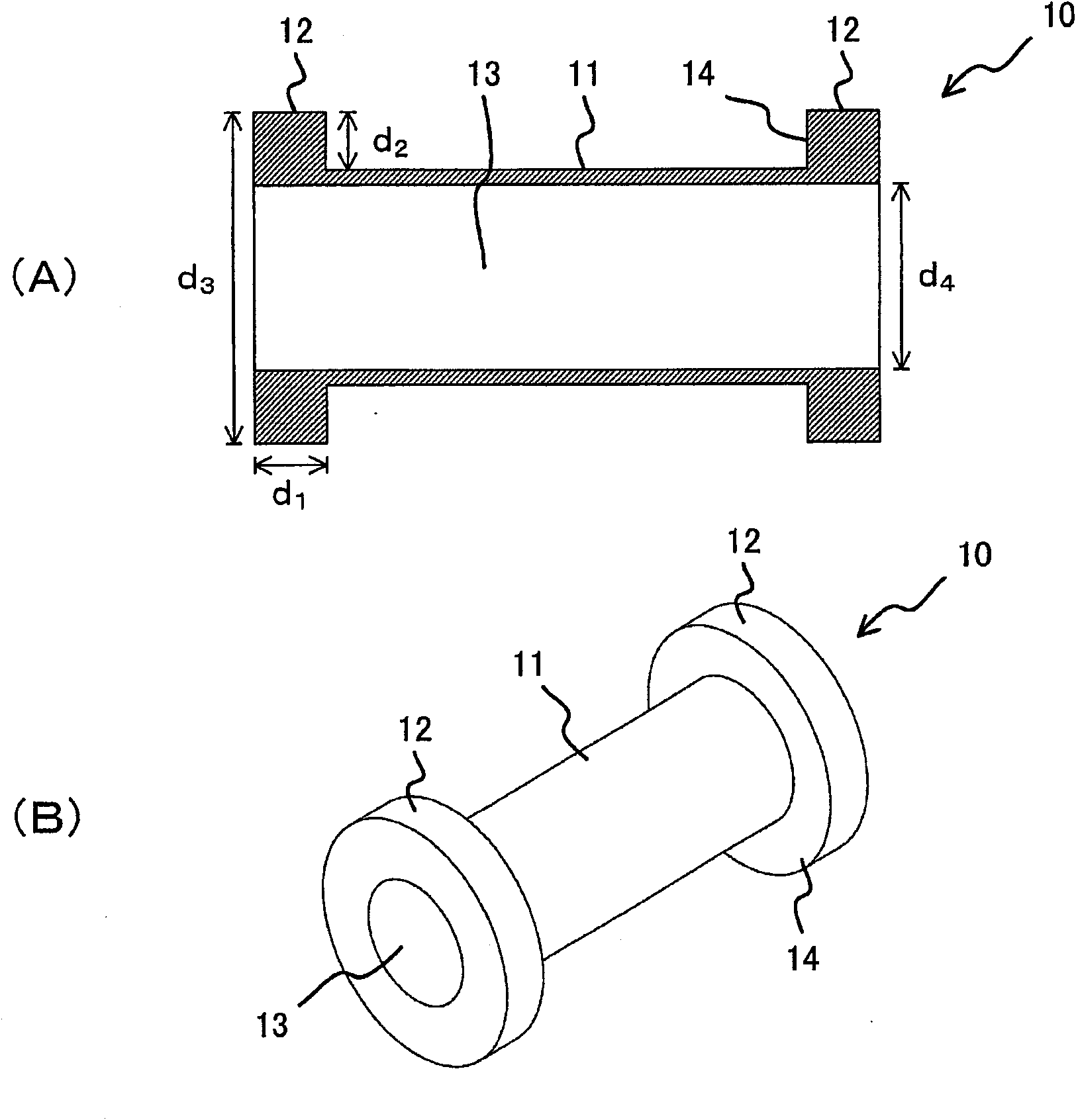

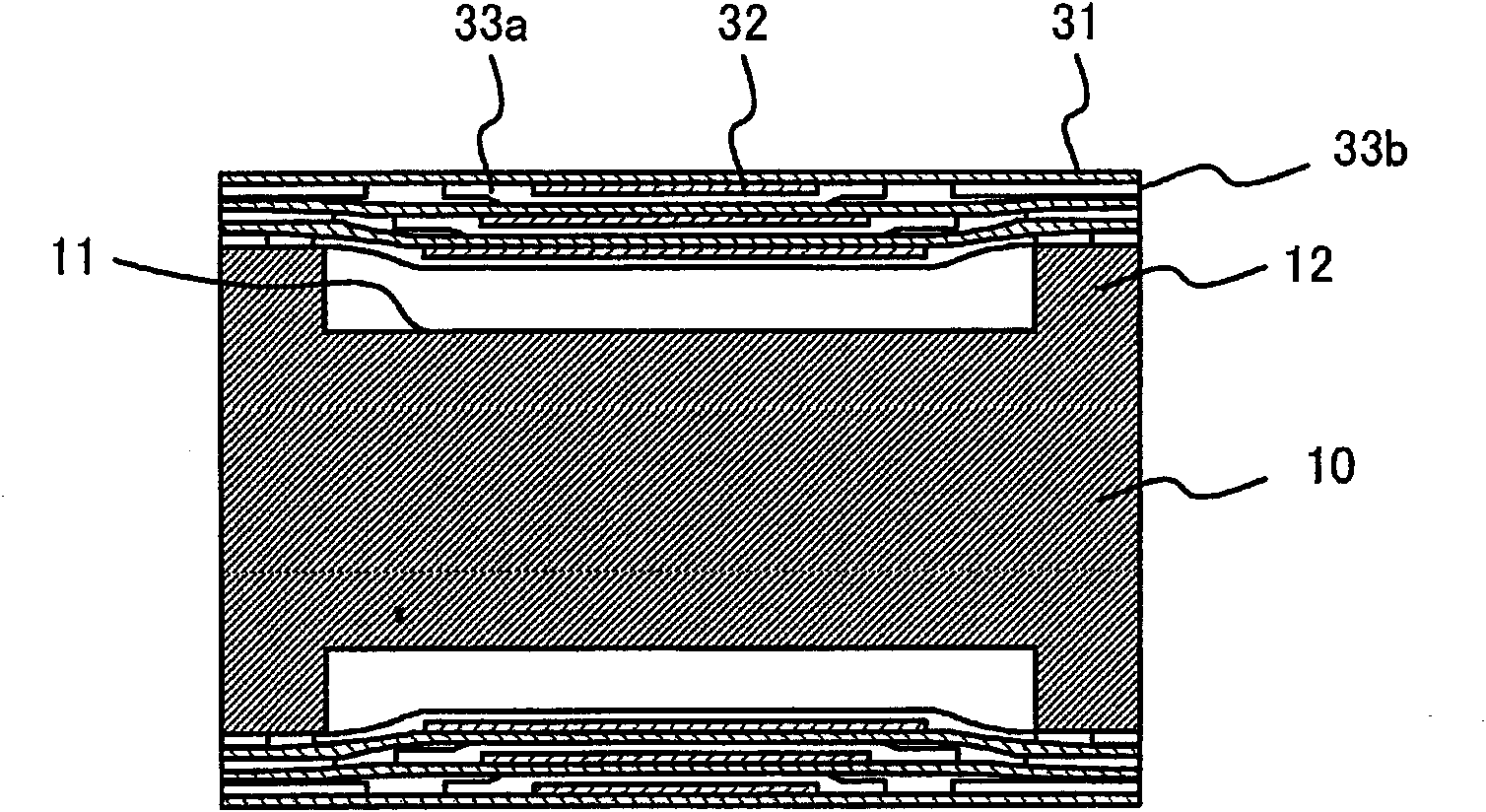

[0066] Such as figure 1 As shown, the winding core 10 of this embodiment is a dumbbell-shaped winding core in which a small-diameter relaxation portion 11 and a large-diameter support portion 12 are formed on the winding surface side of the wafer processing tape. The relaxation portion 11 is provided at a position corresponding to the tape for wafer processing (constituted by the adhesive layer and the label portion of the adhesive film covering the adhesive layer), and the supporting portion 12 supports the peripheral portion 33b of the adhesive film on the outside of the relaxation portion 11. way to form. In addition, a cylindrical hollow portion 13 is formed at the rotation center of the winding core.

[0067] The material of the winding core is not particularly limited, and ABS resin, vinyl chloride resin, iron, and the like can be selected from the viewpoint of ease of handling, weight, and the like.

[0068] (Easy Department 11)

[0069] Such as figure 1 As shown,...

no. 2 approach

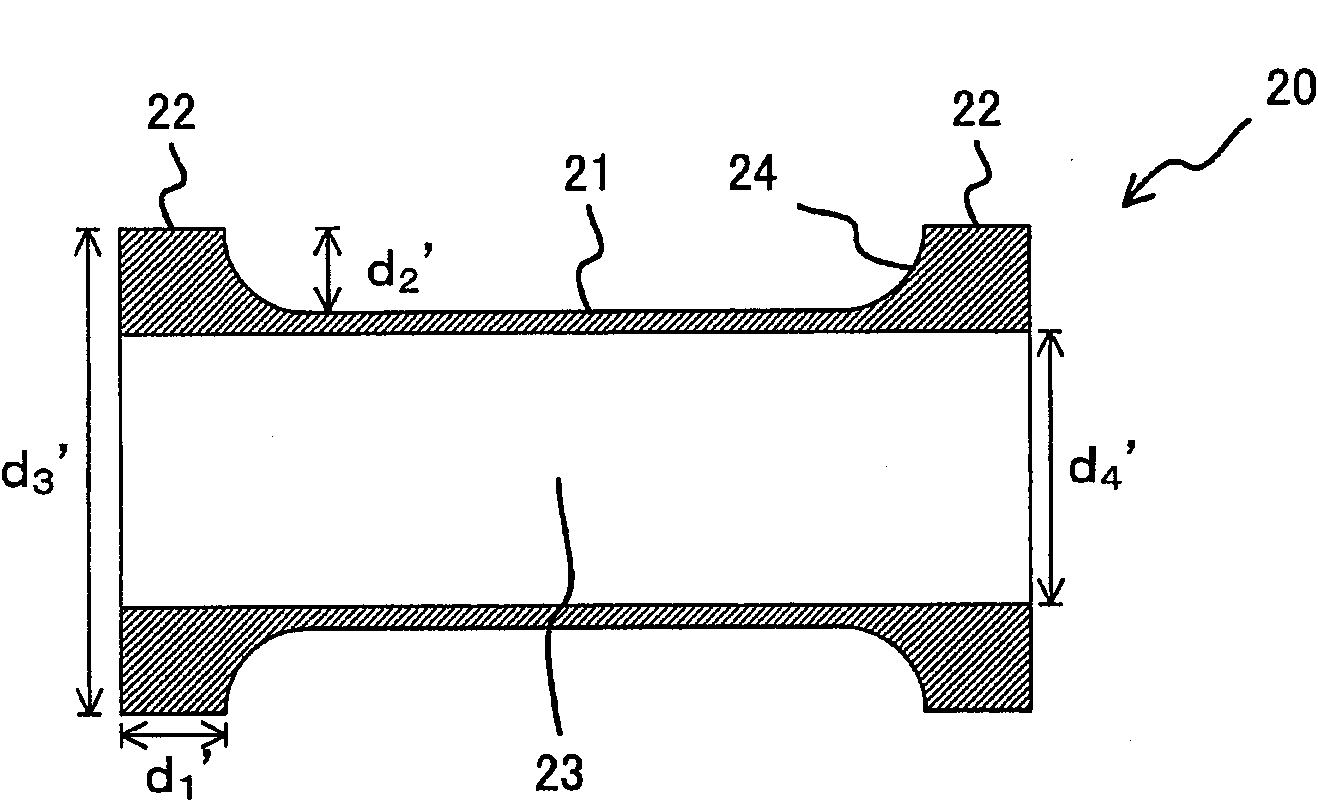

[0076] The winding core 20 of the second embodiment is a winding core in which the relaxation portion side portion 14 of the winding core 10 of the first embodiment is formed into a curved surface. image 3 A cross-sectional view of the winding core 20 of the second embodiment is shown. The winding core 20 is a deformed dumbbell-shaped winding core in which a relaxation portion 21 with a small diameter and a support portion 22 with a large diameter are formed on the winding surface side of the wafer processing tape. Such as image 3 As shown, the relaxation portion 21 is formed by the relaxation portion 21 , which is a cylindrical surface with a smaller diameter than the support portion 22 with respect to the rotation center axis of the winding core 20 , and the relaxation portion side 24 , which is a curved surface continuously curved from the relaxation portion 21 .

[0077]The relaxation portion 21 is provided at a position corresponding to the adhesive layer of the dicing...

Embodiment 1

[0092] Make the diameter of the supporting part (d 3 ) is set to 148mm, the width of the support part (d 1 ) is set to 30mm, and the depth of the relaxation part from the surface of the support part to the surface of the relaxation part (d 2 ) is set to 1.0mm, the diameter of the cavity (d 4 ) was set to 76.2 mm, and the length of the core in the longitudinal direction was set to 290 mm. Furthermore, a dumbbell-shaped core in which the center of the support portion, the relaxation portion, and the hollow portion coincided with the core rotation center was used as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com