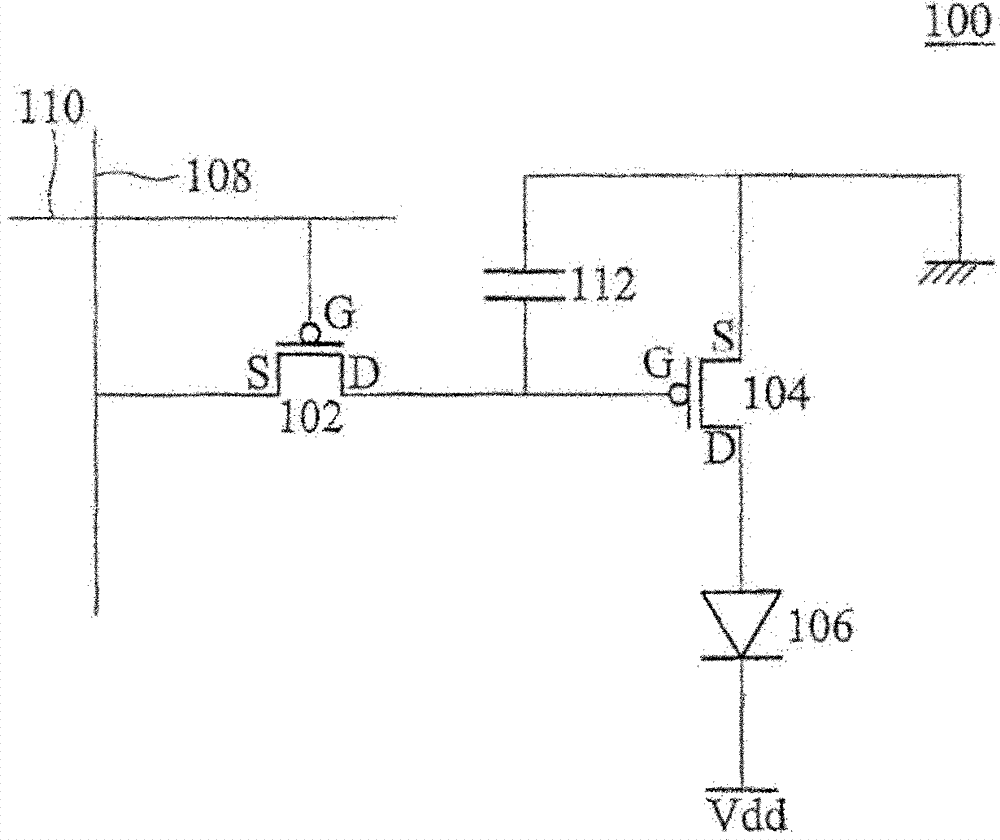

Manufacturing method of organic electroluminescent element and image display system

A technology of electroluminescent components and image display systems, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, and electric solid-state devices, and can solve the problems of large differences in electrical properties of thin-film transistors, so as to increase complexity, increase aperture ratio, Improve the effect of excessive electrical difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

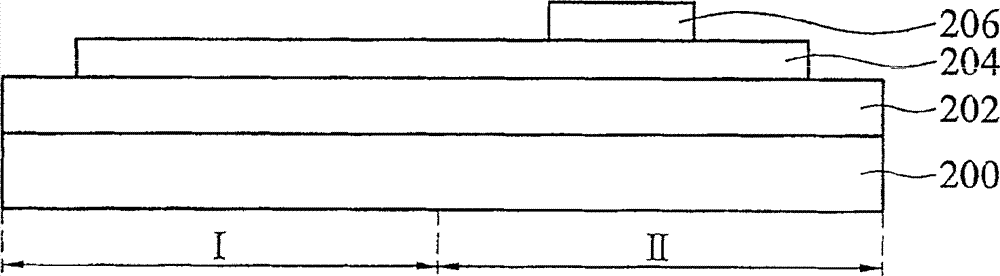

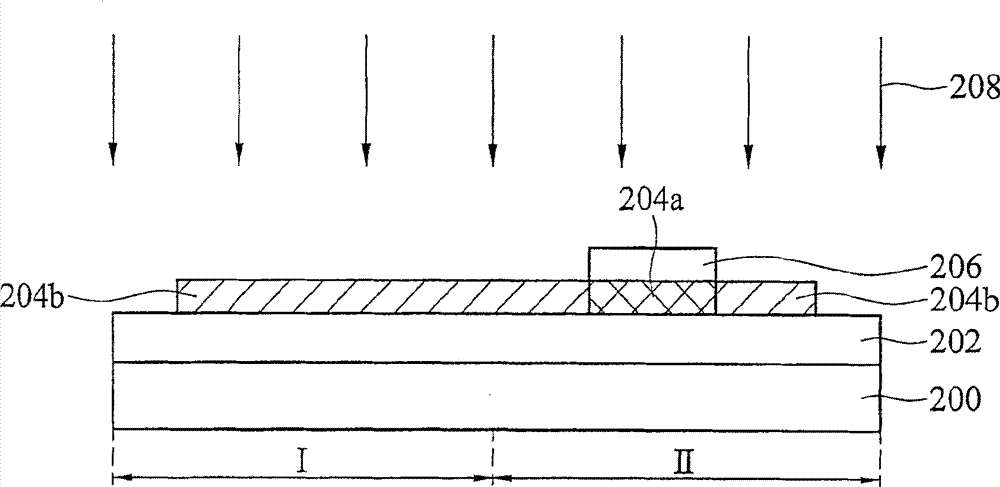

[0023] Figure 2a ~ 2f It is a cross-sectional view illustrating a manufacturing method of an organic electroluminescent element in a preferred embodiment of the present invention.

[0024] Such as Figure 2a As shown, sequentially on the substrate 200 including the first element region (eg, switching thin film transistor (switching thin film transistor) region I) and the second element region (eg, driving thin film transistor (driving thin film transistor) region II) A buffer layer 202 , an amorphous silicon layer 204 and a protection film 206 are formed. Wherein, the protection film 206 is formed on the portion of the amorphous silicon layer 204 in the second device region II; and the protection film 206 includes a material based on silicon, such as silicon oxide (SiOx), silicon nitride (SiNx) , silicon oxynitride (SiOxNy), or a stacked structure of silicon oxide and silicon nitride.

[0025] Such as Figure 2b As shown, an excimer laser annealing process 208 is performe...

no. 2 Embodiment

[0030] Figure 3a ~ 3f It is a cross-sectional view illustrating a manufacturing method of an organic electroluminescent element in another preferred embodiment of the present invention.

[0031] Such as Figure 3a As shown, a buffer layer 302 and an amorphous silicon layer 304 are sequentially formed on a substrate 300 including a switching thin film transistor region I and a driving thin film transistor region II.

[0032] Such as Figure 3b As shown, the amorphous silicon layer 304 is patterned to form a patterned amorphous silicon layer 304b located in the switching thin film transistor region I and a patterned amorphous silicon layer 304a located in the driving thin film transistor region II.

[0033] Such as Figure 3c As shown, a protective film 306 covering the surface of the patterned amorphous silicon layer 304 a and part of the buffer layer 302 is formed. The protective film 306 includes a silicon-based material, such as silicon oxide (SiOx), silicon nitride (Si...

no. 3 Embodiment

[0038] Figure 4a ~ 4g It is a cross-sectional view illustrating a manufacturing method of an organic electroluminescence device in another preferred embodiment of the present invention.

[0039] Such as Figure 4a As shown, a patterned protection film 402 is formed on a substrate 400 including a switching thin film transistor region I and a driving thin film transistor region II. The above-mentioned patterned protective film is located in the region II of the driving thin film transistor. The material of the patterned protection film 402 includes silicon oxide (SiOx), silicon nitride (SiNx), silicon oxynitride (SiOxNy), or a stacked structure thereof.

[0040] Such as Figure 4b As shown, a buffer layer 404 is formed on the patterned protection film 402 and the substrate 400 . Next, an amorphous silicon layer 406 is formed on the buffer layer 404, such as Figure 4c shown.

[0041] Such as Figure 4d As shown, an excimer laser annealing process 408 is performed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com