Electromagnetic brake motor with spiral blade fan

A helical blade, electromagnetic braking technology, applied in electric components, control mechanical energy, electromechanical devices, etc., can solve problems such as affecting the service life of electric motors and friction disc electromagnetic components, failing to break through the single friction disc braking, and increasing the difficulty of product production. , to achieve the effect of good braking capacity, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

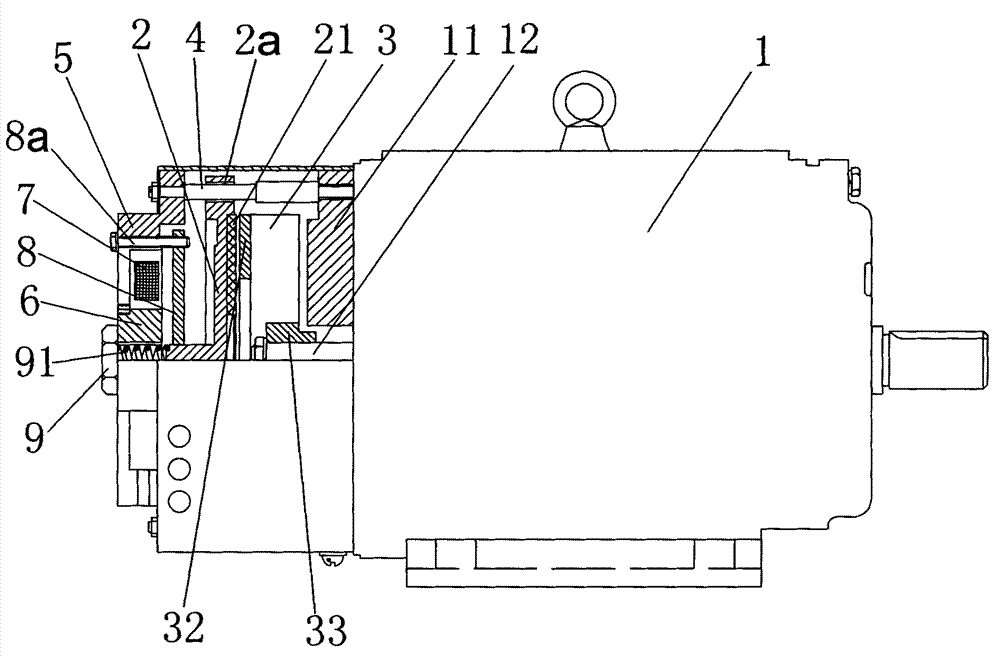

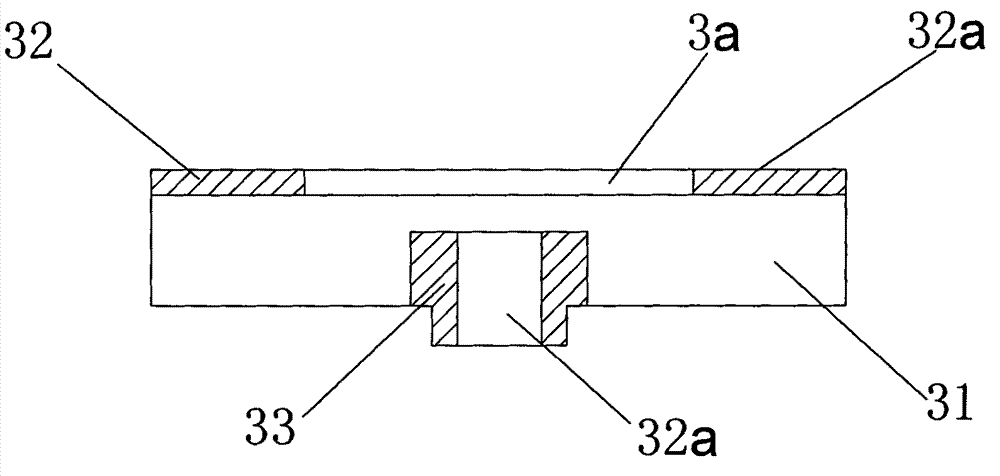

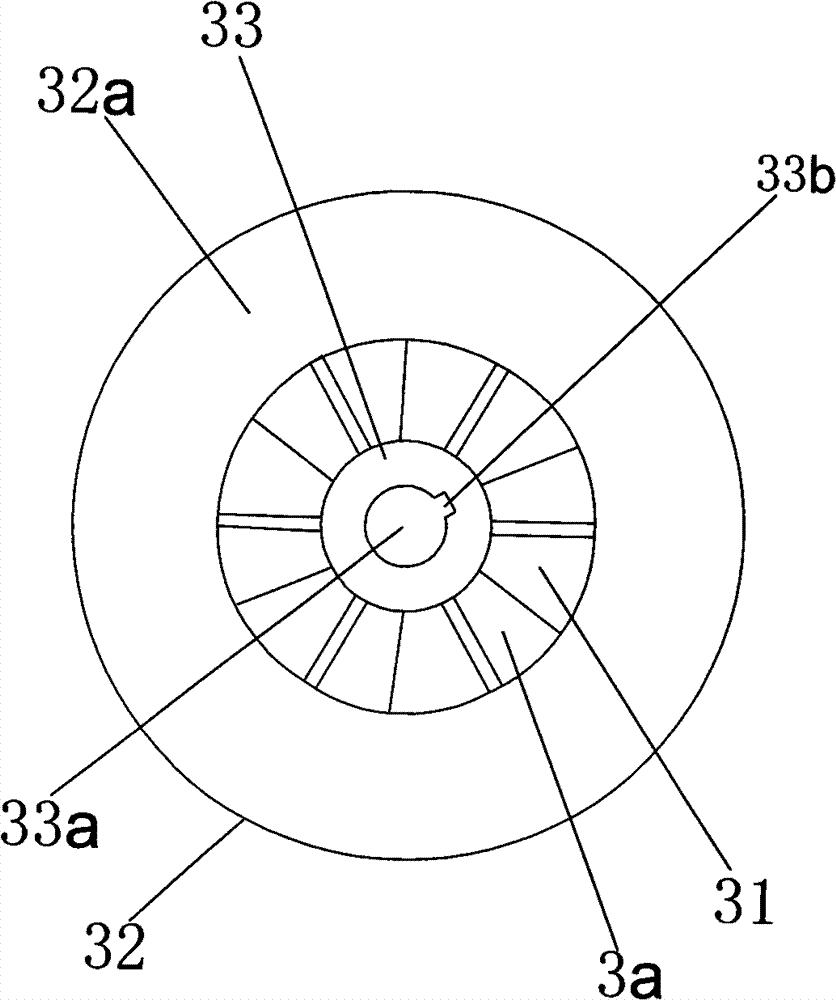

[0022] Figure 1 to Figure 5 Shown as the structural representation of the present invention.

[0023] The reference signs are: motor 1, rear end cover 11, rotating shaft 12, brake disc 2, guide slide hole 2a, asbestos brake plate 21, motor fan 3, air inlet cavity 3a, spiral blade 31, annular Disc 32, braking surface 32a, connecting protrusion 33, assembly through hole 33a, metal keyway 33b, column end cover screw 4, electromagnetic jacket 5, electromagnetic column core 6, electromagnetic coil 7, electromagnetic sucker 8, positioning screw 8a, adjusting bolt 9, pressure spring 91.

[0024] like Figure 1 to Figure 5 As shown, the electromagnetic brake motor with spiral blade fan of the present invention includes an electromagnetic brake fixedly connected to the rear end cover 11 of the motor 1, the electromagnetic brake is slidingly equipped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com