Energy feedback type power unit cascaded high voltage frequency converter

A high-voltage inverter and power unit technology, applied in the direction of converting AC power input into AC power output, irreversible DC power input into AC power output, and output power conversion devices, etc. Coordinated action, bulky and other problems, to achieve the effect of reducing volume and weight, perfect and feasible plan, and eliminating low-frequency pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The product of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments of the present invention.

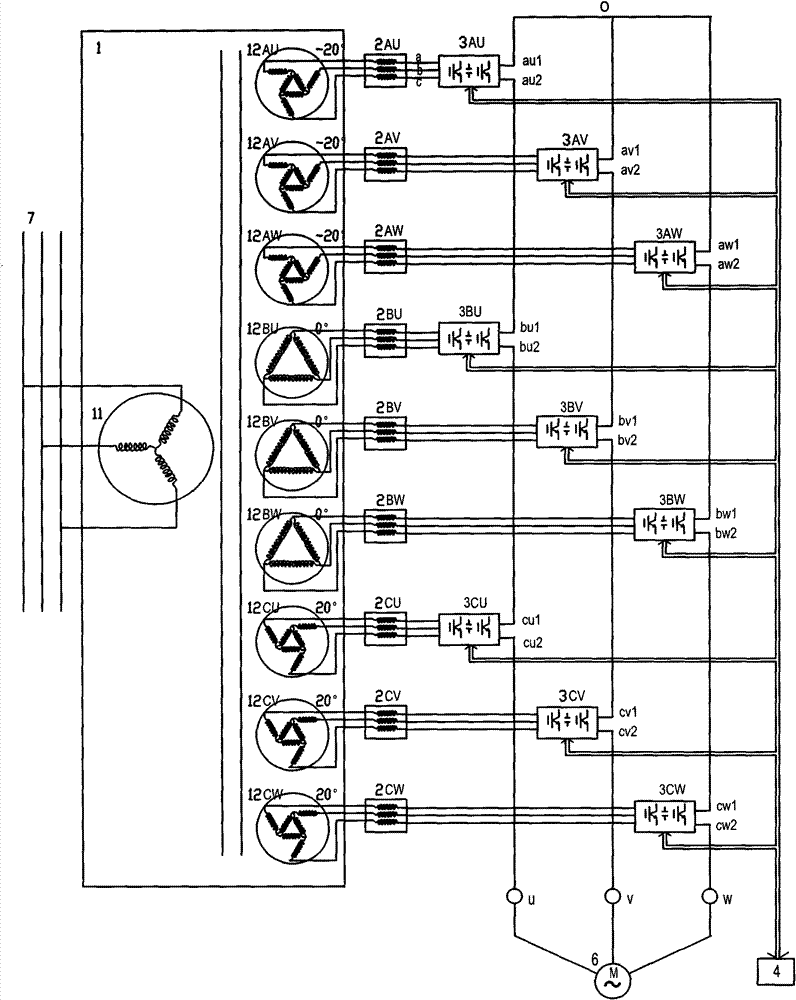

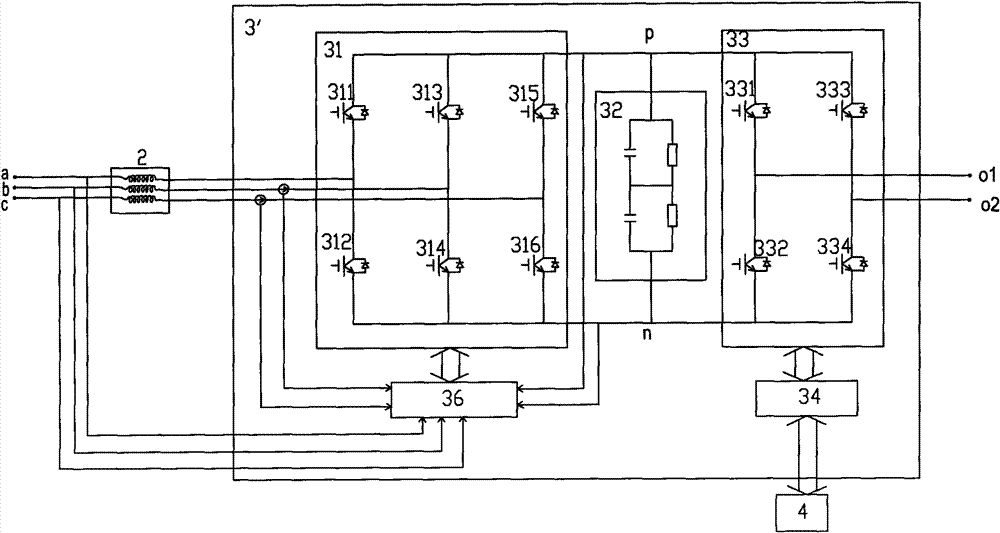

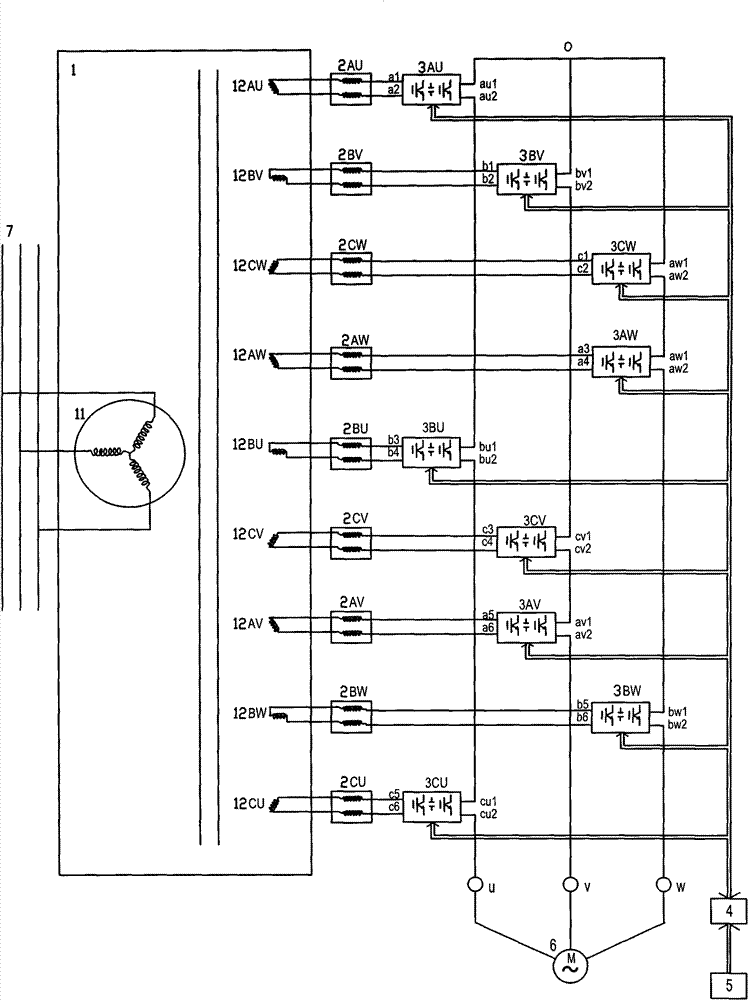

[0056] Here, an energy feedback type high-voltage inverter with three power units connected in series for each phase is used as an example for illustration, as shown in Figure 2A Shown is the schematic diagram of its main circuit wiring, Figure 2B It is the circuit composition of the power unit. The shown high-voltage frequency converter includes a main transformer 1 , 9 reactors (such as 2AU), 9 power units (such as 3AU), a main controller 4 and a sensor circuit 5 .

[0057] The main transformer 1 shown is a three-phase multi-secondary winding transformer, and its primary winding 11 is connected to the three-phase high-voltage power grid 7, and all the secondary windings (such as 12AU) are used as a group, including the same three circuits (such as 12AU / 12BV / 12CW ), each secondary winding (such as 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com