Method and device for starting megawatt-level double-fed motor

A doubly-fed motor and starting device technology, which is applied to the starter of a single multi-phase induction motor, motor generator/starter, single-grid parallel feeding arrangement, etc., can solve the problem of high system cost, impact, increased system cost, etc. problem, to achieve the effect of simple grid connection and speed regulation process, simple system structure and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

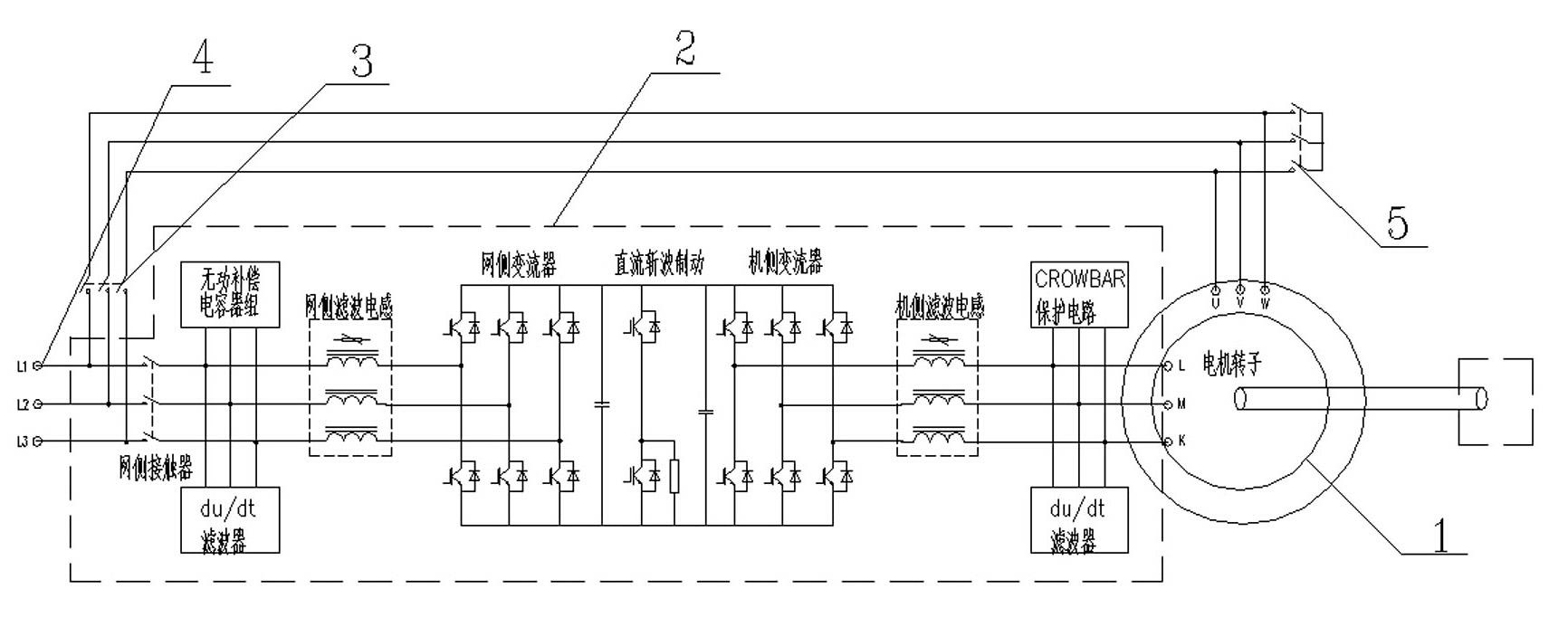

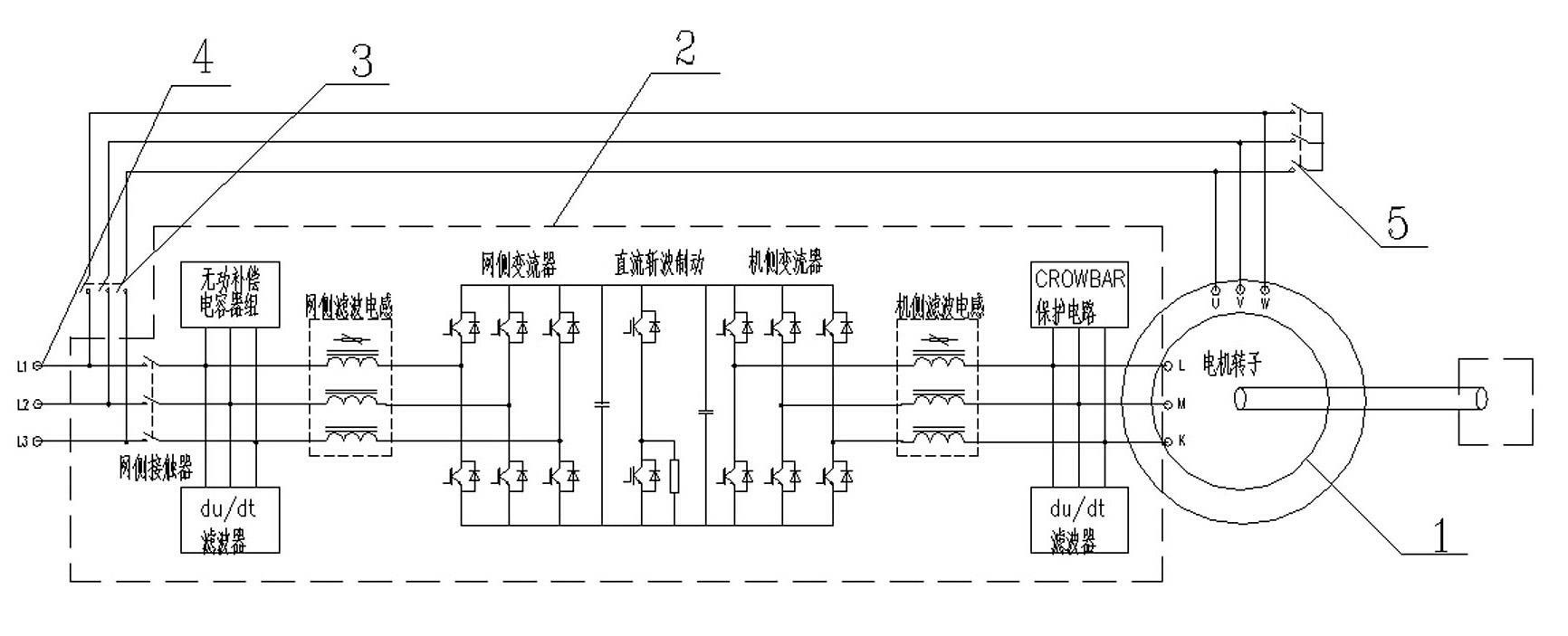

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

[0010] It can be seen from the accompanying drawings that the present invention relates to a method for starting a megawatt-level doubly-fed (wound rotor) motor. (Voltage) generates a rotating magnetic field, so that the stator winding short-circuited by the stator short-circuit contactor generates an induced current and a stator magnetic field, so that the motor generates electromagnetic torque to drive the rotor to rotate, and realizes the zero-speed start of the doubly-fed (wound rotor) motor.

[0011] As one of the specific implementations of the above method, on the basis of a conventional doubly-fed (wound rotor) motor rotor side frequency converter to realize the frequency conversion speed control device of the motor, by adding a stator short-circuit contactor 5 on the stator side, when After the rotor speed reaches the flexible grid-connected speed of the doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com