Reflector for illumination device of motor vehicle and manufacturing method

A lighting device and reflector technology, applied in the reflector field, can solve the problems of difficulty, expensive reflector painting, fine structure installation, etc., and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

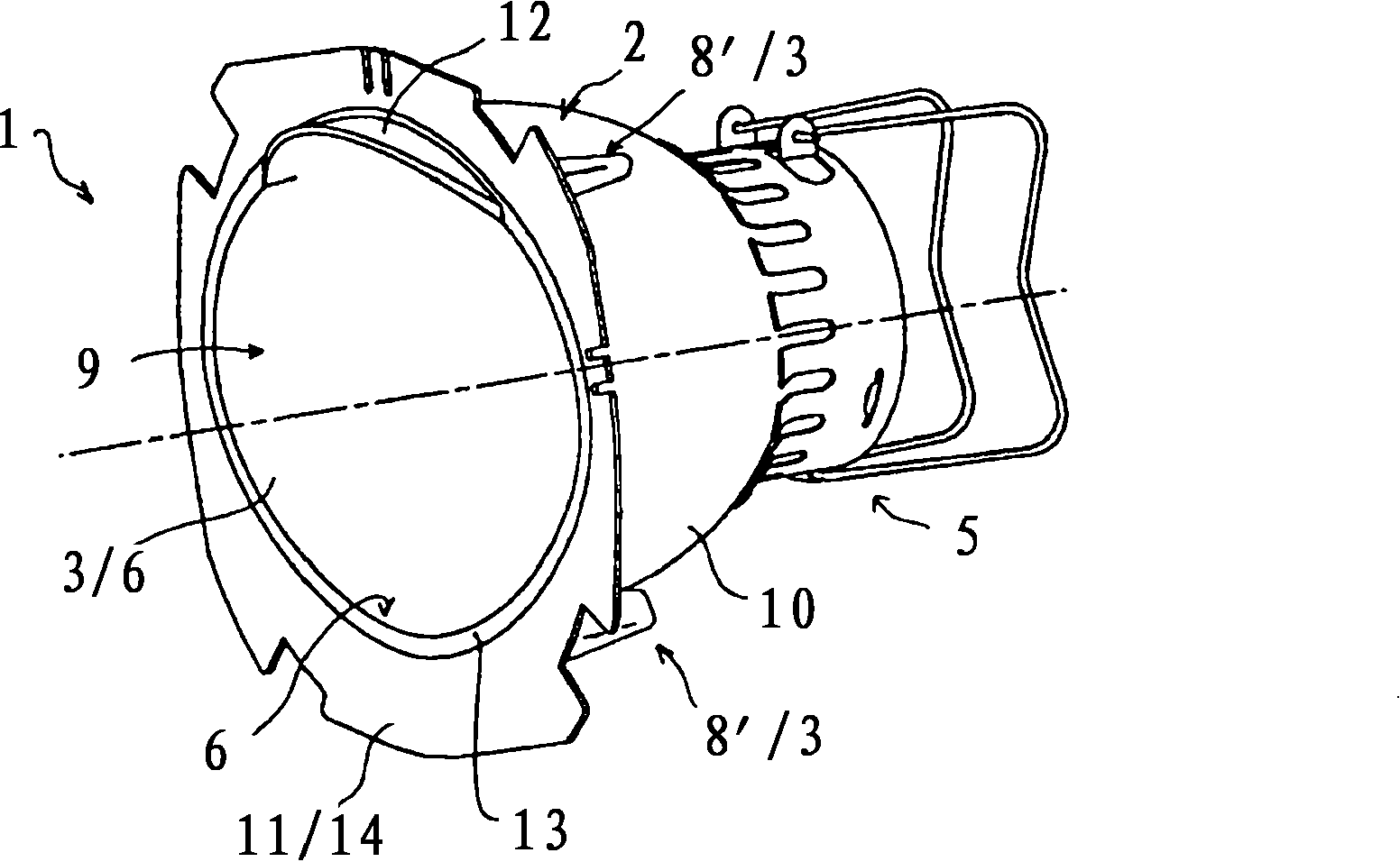

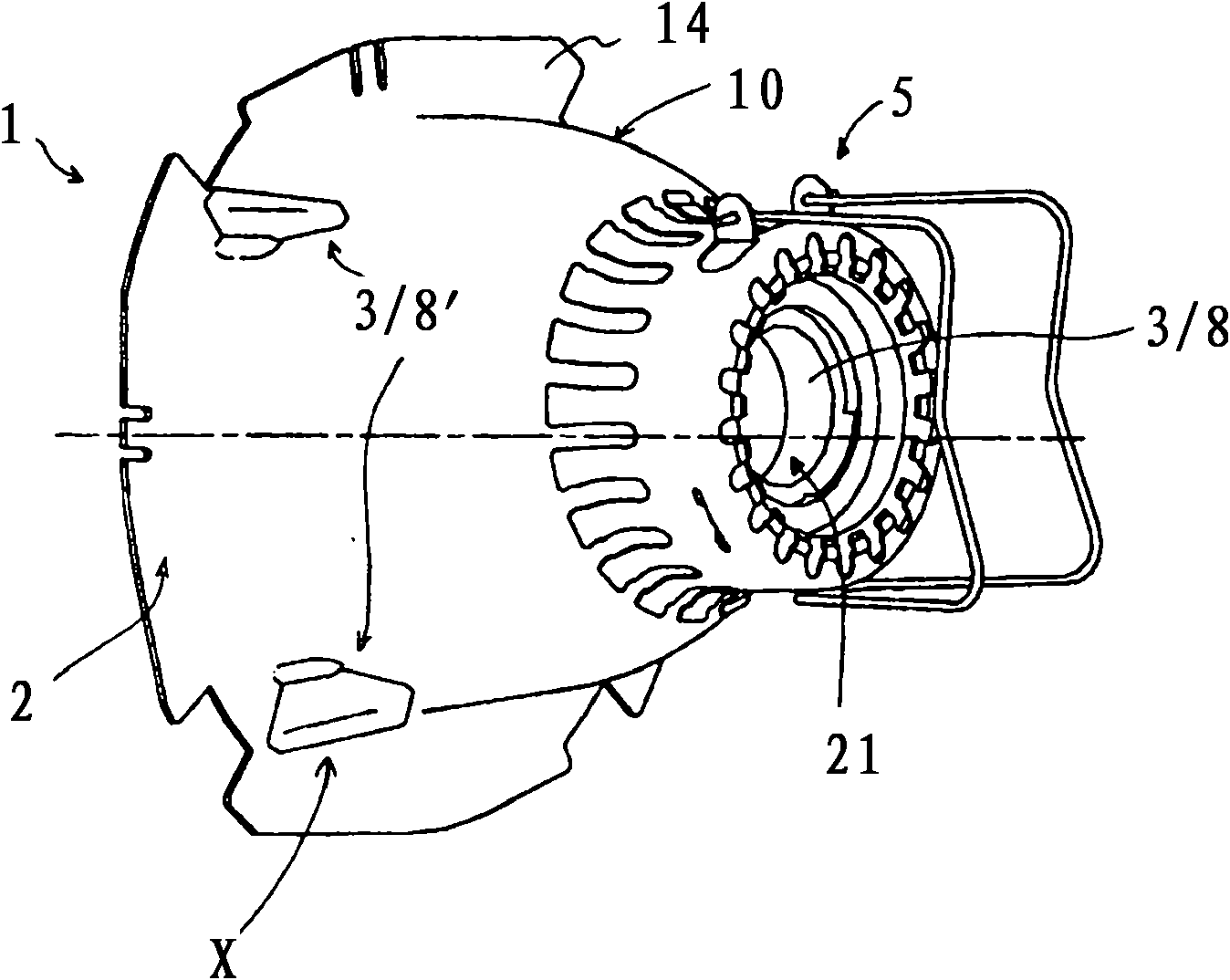

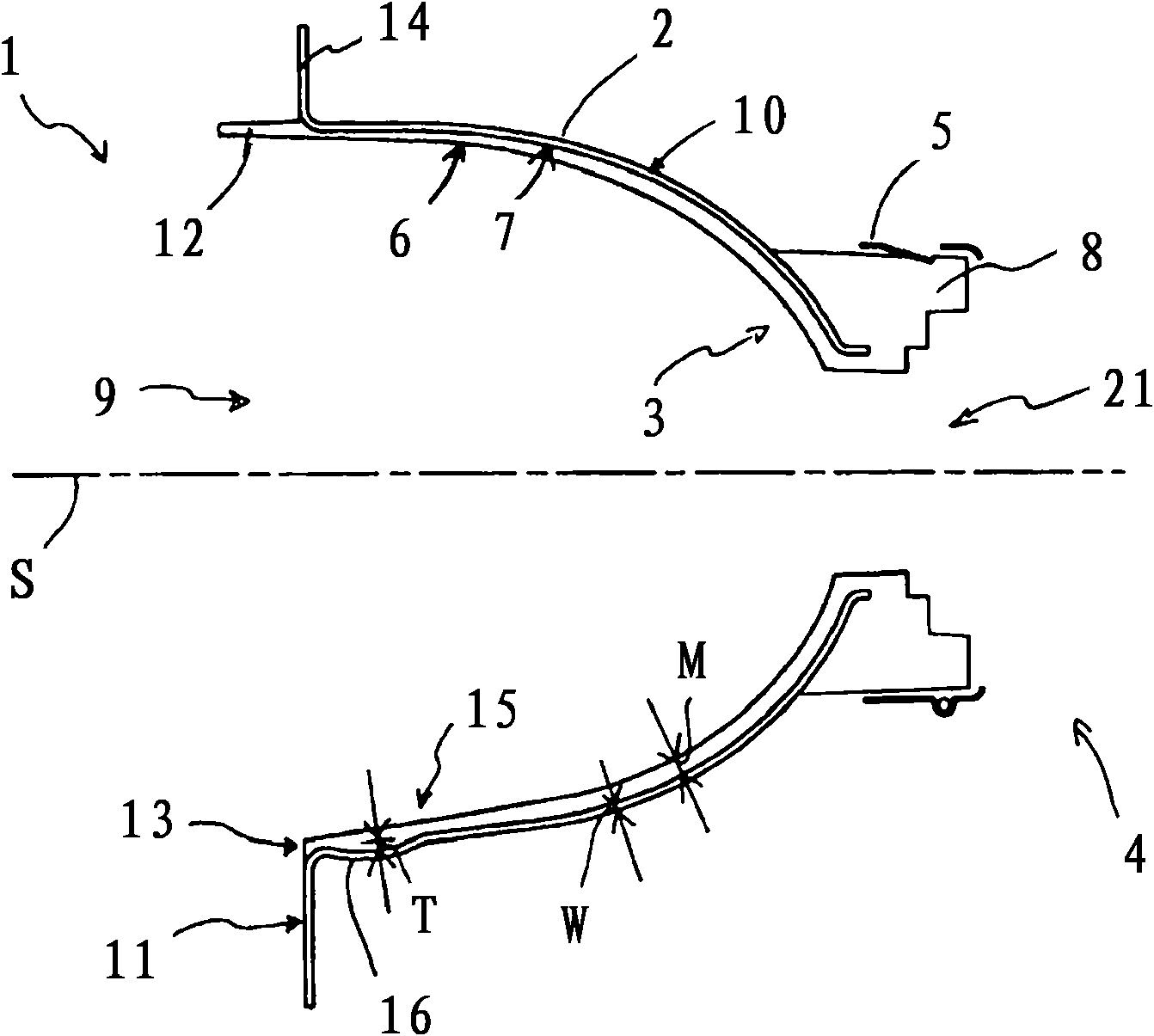

[0026] The reflector 1 for the lighting device of the automobile mainly comprises a bowl-shaped base body 2, an injection molding element 3 applied on the bowl-shaped base body 2, and a support 5 for a lamp, said support being mounted on a lamp holder of the base body Compatible with base body 2 in zone 4. The injection-molded element 3 forms a reflective surface 6 which is applied in a planar manner to the inner side 7 of the base body 2 . The lighting device can be designed as a headlight or as a signal light.

[0027] In addition to the reflective surface 6 , the injection molded element 3 also has further shaped sections, which are designed as connecting sections 8 , 8 ′ for connecting the reflector 1 to other functional components not shown. In the socket region 4 of the reflector 1 , the connecting section 8 is formed forming the opening 21 in such a way that a light source (not shown) can be positioned precisely and coaxially with the base body 2 and held on the reflec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com