Large particle impact dust falling device for air inlet of electrostatic precipitator of boiler

A technology of electrostatic precipitator and dust suppression device, which is applied in the direction of electrostatic separation, separation of dispersed particles, chemical instruments and methods, etc., can solve the problem of not blocking large particle dust dust suppression device, etc., and achieves simple structure, convenient manufacture and installation, and wide applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

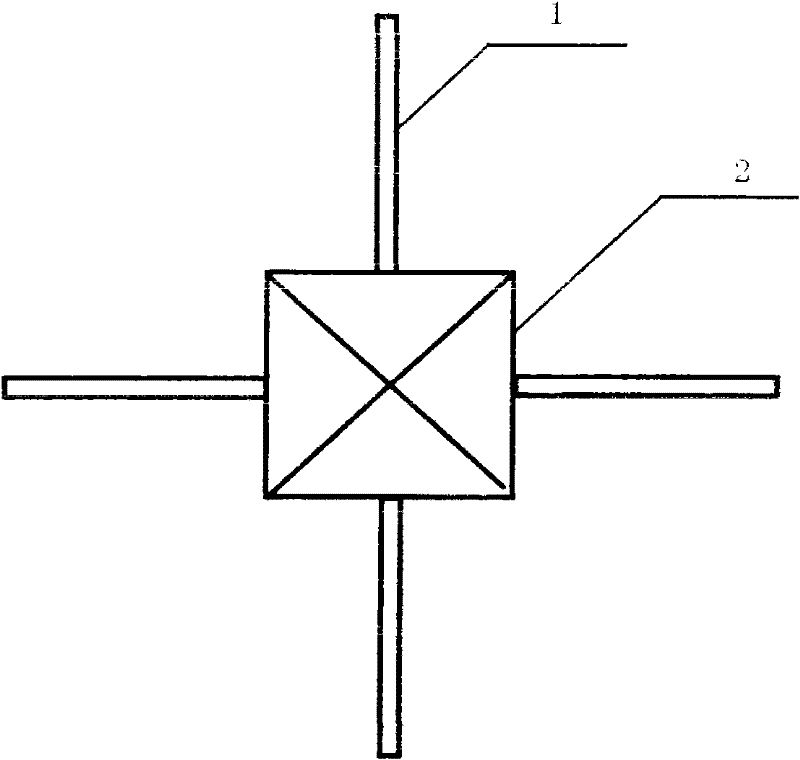

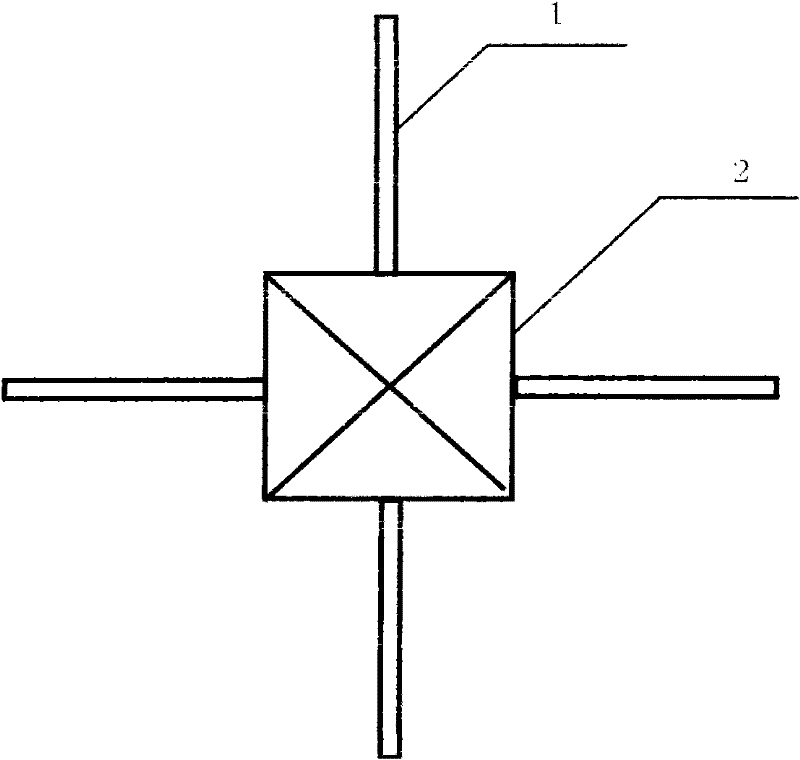

[0017] As shown in the accompanying drawings, the main body 1 of the large particle collision dust-reducing device at the air inlet of the boiler electrostatic precipitator disclosed by the present invention is a square cone structure composed of 4 triangular collision plates, the head of the square cone is closed, and the rear part is open. The angle is set according to the square cone angle of the air inlet of the electrostatic precipitator, and the support device 2 is fixedly connected with the air inlet of the electrostatic precipitator on the cone. The installation is determined according to the size of the air inlet of the electrostatic precipitator and related dimensions. distance.

[0018] When the large particle dust enters the inlet of the electrostatic precipitator, it first touches the large particle collision device of the square cone interface, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com